Description

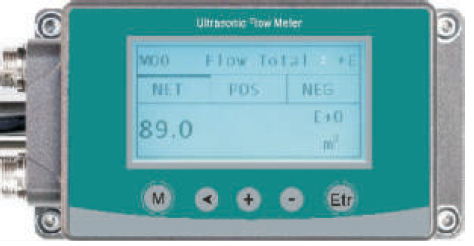

An ultrasonic flow meter is a type of flow meter that measures the velocity of a fluid with ultrasound to calculate volume flow. Using ultrasonic flow meter, the meter can measure the average velocity along the path of a beam of ultrasound.

By averaging the difference in measured transit time between pulses of ultrasound into and against direction of the flow.

It can also be done by measuring the frequency shift from the Doppler effect. Ultrasonic flow meters are affected by acoustics of the fluid and are impacted by temperature, density, viscosity and suspended particulates on the flow meter.

They vary in price but are inexpensive to use and maintain because they lack moving parts, unlike mechanical meters.

In-line sensors also have

- Guaranteed accuracy thanks to traceable factory calibration

- Robust industrial design in accordance with ASME and EN

- Short inlet runs

- For pipelines up to 8″

Ultrasonic Flow Meter Features:

- The unique isolated sensor design allows for replacement without breaking the process seal

- Increase plant availability and reduce potential leak points with a gasket-free meter body with no moving parts

- Eliminate downtime and maintenance costs associated with plugged impulse lines with a non-clog meter body design

- Achieve vibration immunity with a mass balanced sensor and Adaptive Digital Signal Processing with visual filtering

- A standard internal signal generator included in every meter simplifies electronics verification

- All meters arrive pre-configured and hydrostatically tested, hence making them ready and easy to install

- Simplify SIS compliance with available dual and quad Vortex

Also, If this flow meter does not meet your application requirements pls select the following: Coriolis or mass, Vortex , Turbine or electromagnetic.

Industries ranging from oil & gas and municipal/wastewater to building automation and factory automation to solar and semicon.

Finally, Pls Request a quote on ultrasonic flow meters for your application, or Contact SRS to learn more.

Q&A

A Q&A, or Question and Answer session, is a common format used to exchange information and address specific queries related to a particular topic. In the context of Ultrasonic Flow Meters, a Q&A session could involve individuals asking questions about the functioning, installation, calibration, troubleshooting, and other aspects of Q&A Ultrasonic Flow Meters.

In a Q&A, experts or knowledgeable individuals provide answers to these questions and share insights, best practices, and technical knowledge related to Ultrasonic Flow Meters. This can help attendees gain a better understanding of Ultrasonic Flow Meters and address any concerns or uncertainties they may have.

Q&A Ultrasonic flow meters are instruments used to measure the flow rate of liquids or gases in pipes or ducts. They use ultrasonic technology to determine the velocity of the fluid flow and calculate the volumetric flow rate.

Here are some commonly asked questions about ultrasonic flow meters:

Q: What are ultrasonic flow meters?

A: An ultrasonic flow meter is a type of flow meter that measures the flow of liquids or gases by transmitting ultrasonic sound waves through the fluid and measuring the time it takes for the waves to travel from one transducer to another.

Q: How do ultrasonic flow meters work?

A: Ultrasonic flow meters typically consist of two transducers that are placed on opposite sides of a pipe or channel. One transducer sends ultrasonic sound waves through the fluid, while the other transducer receives the sound waves. By measuring the time it takes for the sound waves to travel between the two transducers, the ultrasonic flow meter can calculate the velocity of the fluid and the flow rate.

Q: What are some applications of ultrasonic flow meters?

A: Ultrasonic flow meters are commonly used in a variety of industries, including water and wastewater treatment, chemical processing, oil and gas production, and HVAC systems. They are often used to measure the flow of liquids and gases in pipelines. It is also use to measure the flow in tanks, boilers, and other process equipment.

Q: What are the advantages of using ultrasonic flow meters?

A: Ultrasonic flow meters offer several advantages over other types of flow meters, including high accuracy, non-invasiveness, and the ability to measure flow without the need for a straight pipe run. They are also well-suited for use in applications where the fluid being measured contains solids or bubbles, as ultrasonic sound waves can penetrate through these particles and bubbles.

Q: What factors should be considered when selecting an ultrasonic flow meter?

A: When selecting an ultrasonic flow meter, several factors should be considered, including the specific application. This is the type of fluid being measured, the flow rate and range, and the required accuracy and resolution. Other factors to consider include the operating temperature and pressure range. Also, the type of output signal required, and the installation and maintenance requirements.

Q: What are some limitations of Q&A Ultrasonic Flow Meters?

A: One limitation of ultrasonic flow meters is that they may not be suitable for use with highly viscous fluids. Because the sound waves may be absorbed or scattered by the fluid. Additionally, ultrasonic flow meters may not be as accurate as other types of flow meters at low flow rates. At low flow rates, they may be more prone to errors in applications where the fluid is turbulent. It may also be an issue if it contains high levels of suspended solids or bubbles. Finally, ultrasonic flow meters may be more expensive than other types of flow meters. Especially in particular for larger pipe sizes or high-pressure applications.

Q: What are the different types of ultrasonic flow meters?

A: There are two main types of ultrasonic flow meters: transit-time and Doppler flow meters. Transit-time flow meters measure the time it takes for an ultrasonic signal to travel upstream and downstream through the fluid. Once it travels, it uses this information to calculate the velocity and flow rate. Doppler flow meters, on the other hand, use the Doppler effect to measure the frequency shift of an Ultrasonic Flow meter signal. This signal is reflected off the particles in the fluid. This frequency shift is then used to calculate the velocity and flow rate of the fluid.

Q: How do ultrasonic flow meters compare to other types of flow meters?

A: Compared to other types of flow meters, ultrasonic flow meters are generally more accurate and reliable than mechanical flow meters. More accurate than turbine or variable area flow meters. They are also non-invasive and can be used to measure flow without the need for cutting into the pipe or interrupting the flow. However, ultrasonic flow meters may not be as accurate as magnetic flow meters in some applications. They are particularly accurate in applications with low-conductivity fluids or fluids with high levels of suspended solids. Additionally, ultrasonic flow meters may be more expensive than some other types of flow meters. they are more expensive, for larger pipe sizes or high-pressure applications.

Q: What are some installation considerations for ultrasonic flow meters?

A: When installing an ultrasonic flow meter, several factors should be considered, including the pipe diameter and material. The presence of obstructions or bends in the pipe and the orientation and spacing of the transducers. For accurate flow measurement, it is important to ensure that the ultrasonic signal is not affected by air pockets. Another issue to make sure that don’t affect the ultrasonic signal is turbulence in the fluid. Additionally, it may be necessary to install the ultrasonic flow meter in a location. Must be set up so that is easily accessible for maintenance or calibration.

Q: What are some maintenance requirements for ultrasonic flow meters?

A: Q&A Ultrasonic Flow Meters typically require little maintenance, but regular calibration is recommended to ensure accurate flow measurement. Additionally, it may be necessary to periodically clean the transducers or remove any obstructions in the flow stream. If you don’t, that could interfere with the ultrasonic signal. Finally, it is important to follow the manufacturer’s guidelines for installation, operation, and maintenance. This will ensure reliable and accurate flow measurement.

Buy Ultrasonic Flow Meters?

Advantages / Disadvantages

Advantages of Ultrasonic Flow Meters:

- Non-intrusive: Ultrasonic flow meters do not require cutting into pipes, making them suitable for non-invasive flow measurement, reducing potential leaks and installation time.

- Versatile: They can be used for a wide range of liquids, including clean, dirty, aerated, and corrosive fluids, as well as for various pipe sizes and materials.

- Accurate: Ultrasonic flow meters provide high accuracy and repeatability, often within a range of 0.5% to 1% of the measured value.

- Low maintenance: Generally, these meters require minimal maintenance, contributing to reduced operational costs and downtime.

Disadvantages of Ultrasonic Flow Meters:

- Cost: Ultrasonic flow meters may have a higher initial purchase cost compared to some other flow meter technologies, which can be a consideration in the selection process.

- Sophistication: They require skilled installation and setup to ensure proper functioning and accurate measurements, which may require specialized expertise.

- External noise: In some cases, external noise or vibrations near the pipe can interfere with the ultrasonic signals, potentially affecting measurement accuracy.

- Flow profile sensitivity: Ultrasonic flow meters may require a fully developed flow profile to ensure accurate measurements, which can be a limitation in some piping configurations.

These advantages and disadvantages should be considered when evaluating the suitability of ultrasonic flow meters for specific applications.