Flow

What are Flow Meters?

Flow measurement is the quantification of bulk fluid movement. The flow can be measured in a variety of ways. Positive-displacement flow meters accumulate a fixed volume of fluid and then count the number of times the volume is filled to measure flow.

Other flow measurement methods rely on forces produced by the flowing stream as it overcomes a known constriction, to indirectly calculate flow. Flow may be measured by measuring the velocity of fluid over a known area.

Many flow meters can resolve this issue. You can use Ultrasonic, Turbine, Vortex, Electromagnetic, and Coriolis types.

Types of Flow Meters SRS DIRECT is offering?

Vortex Flow Meter

Vortex Flow Meters. A vortex flow meter is suitable for flow rate or flow totalization measurements in industrial grade, brass, or all plastic models.

Its sensitivity to variations is low in process conditions and low wear relative to other types of flow meters.

Ultrasonic Flow Meter

An ultrasonic flow meter is a type of flow meter that measures the velocity of a fluid with ultrasound to calculate volume flow. Using ultrasonic transducers, the flow meter can measure the average velocity. It can also measure along the path of an emitted beam of ultrasound.

It does this by averaging the difference in measured transit time between the pulses of ultrasound propagating into and against the direction of the flow. Moreover, it uses it to measure the frequency shift from the Doppler effect.

Also, Ultrasonic flow meters are affected by the acoustic properties of the fluid and can be impacted by temperature, density, viscosity, and suspended particulates depending on the exact flow meter.

They vary greatly in purchase price but are often inexpensive to use and maintain. This is because they do not use moving parts, unlike mechanical flow meters.

Turbine Flow Meter

The Turbine flow meter is a machine that calculates the flow and pressure of liquid passed by the wheel placed in the liquid or gas. In general, the case turbine flow is known as the axial turbine.

Mass Coriolis Flow Meter

How Coriolis Mass Flowmeters Work

Coriolis mass flowmeters measure the force resulting from the acceleration caused by mass moving toward (or away from) a center of rotation. This effect can be experienced when riding a merry-go-round.

It is where moving toward the center will cause a person to have to “lean into” the rotation to maintain balance.

As related to flowmeters, the effect can be demonstrated by flowing water in a loop. It is a loop of flexible hose that is “swung” back and forth in front of the body with both hands.

Because the water is flowing toward and away from the hands, opposite forces are generated and cause the hose to twist. They represent about 21% of all flowmeters sold.

In a Coriolis mass flowmeter, the “swinging” is generated by vibrating the tube(s) in which the fluid flows. The amount of twist is proportional to the mass flow rate of fluid passing through the tube(s).

Sensors and a Coriolis mass flowmeter transmitter are used to measure the twist and generate a linear flow signal.

Electromagnetic Flow Meter

A common flow meter (like a differential pressure and positive displacement flow meter) is the magnetic flow meter. Also technically an electromagnetic flow meter or more commonly just called a mag meter.

The magnetic field is applied to the metering tube, which results in a potential difference proportional to the flow velocity. This is also proportional perpendicular to the flux lines.

Also, the physical principle at work is electromagnetic induction. The magnetic flow meter requires a conducting fluid. For example, water that contains ions, and an electrical insulating pipe surface, for example, a rubber-lined steel tube.

In addition, if the magnetic field direction were constant, electrochemical and other effects at the electrodes would make the potential difference difficult to distinguish. It would be difficult to distinguish from the fluid flow-induced potential difference.

To mitigate this in modern magnetic flowmeters, the magnetic field is constantly reversed. This cancels out the electrochemical potential difference, which does not change direction with the magnetic field.

however, this prevents the use of permanent magnets for magnetic flowmeters.

Showing all 11 results

-

Coriolis Flow Meter and Mass Meters

$ 7,948.00 – $ 48,645.00Select options -

Flow Switch

$ 225.00 – $ 295.00Select options -

Electromagnetic Flow Meter

$ 1,681.65 – $ 5,827.50Select options -

Turbine Flow Meters

Read more -

Micro Mass Flow Meter

$ 1,236.00 – $ 1,376.00Select options -

Density Flow Meter

$ 2,425.00 – $ 3,425.00Select options -

Thermal Mass Flow Meter

Read more -

Variable Area Flow Meter

$ 1,425.00 – $ 6,415.00Select options -

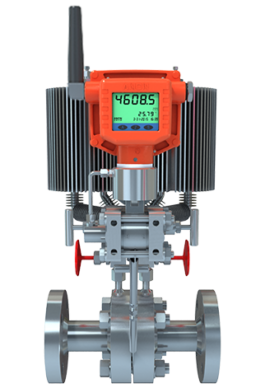

Wireless Flow Meter

$ 2,548.00 – $ 8,345.00Select options -

Ultrasonic Flow Meter

Read more -

Vortex Flow Meter

Read more