Static Mixers

$ 45.00 – $ 2,745.00

Static mixers are essential devices used in various industries to mix fluids without any moving parts. These mixers rely on the principles of fluid dynamics and turbulence to achieve efficient blending. The design consists of a series of carefully engineered internal elements housed within a cylindrical or rectangular body, which creates a continuous, controlled mixing action as fluids pass through.

As fluids enter the static mixer, they are divided, recombined, and subjected to radial mixing, resulting in a homogeneous mixture. This process is achieved by the internal elements, which can be helical, corrugated, or grid-like structures. These elements ensure thorough mixing by creating turbulence and shear forces, which enhance the distribution of fluid components across the entire flow stream.

Static mixers are widely used in industries such as chemical processing, water and wastewater treatment, oil and gas, food and beverage, and pharmaceuticals. Their applications range from blending reactants, diluting solutions, and homogenizing liquids to mixing additives and emulsifying water and oil.

The advantages of static mixers include high reliability due to the lack of moving parts, energy efficiency as they require no external power source, and consistent mixing performance. Their compact design allows for easy installation in existing piping systems, making them versatile and adaptable to various processes.

However, static mixers do have some limitations, such as the potential for pressure drop across the mixer and limited adjustability once installed. Despite these challenges, static mixers remain a popular choice for efficient and reliable fluid mixing in numerous industrial applications.

Description

Static mixers are devices designed to mix fluids without moving parts. They are commonly used in various industries, including chemical processing, water and wastewater treatment, oil and gas, food and beverage, and pharmaceuticals. In addition, the primary function of static mixers is to blend two or more fluid streams into a homogeneous mixture. They achieve this by using a series of carefully designed internal elements that induce turbulence and promote mixing as the fluids pass through the mixer. Finally, this detailed overview will cover the principles, construction, operation, applications, advantages, and disadvantages of static mixers.

Static mixers are devices designed to mix fluids without moving parts. They are commonly used in various industries, including chemical processing, water and wastewater treatment, oil and gas, food and beverage, and pharmaceuticals. In addition, the primary function of static mixers is to blend two or more fluid streams into a homogeneous mixture. They achieve this by using a series of carefully designed internal elements that induce turbulence and promote mixing as the fluids pass through the mixer. Finally, this detailed overview will cover the principles, construction, operation, applications, advantages, and disadvantages of static mixers.

Principles of Operation

The operation of static mixers is based on the principles of fluid dynamics and turbulence. As fluids pass through the mixer, they are subjected to multiple stages of division, recombination, and radial mixing. Furthermore, the internal elements of the mixer create turbulence and shear forces, which help to disperse and mix the fluid streams. The design of these elements is crucial, as they determine the efficiency and effectiveness of the mixing process.

Division and Recombination

One of the key mechanisms of static mixers is the division and recombination of fluid streams. In addition, the internal elements divide the fluid into multiple smaller streams, which are then recombined further downstream. Also, this process repeats multiple times as the fluid moves through the mixer, resulting in a thorough blending of the fluid components.

Radial Mixing

Radial mixing involves the movement of fluid from the center of the pipe to the walls and vice versa. Furthermore, this movement helps to distribute the fluid components evenly across the cross-section of the pipe, ensuring a homogeneous mixture. Also, the internal elements of the static mixer create flow patterns that enhance radial mixing.

Construction of Static Mixers

Static mixers are typically constructed from materials such as stainless steel, PVC, or other corrosion-resistant alloys. Furthermore, the choice of material depends on the properties of the fluids being mixed and the operating conditions. A static mixer consists of the following main components:

Housing

The housing is the outer shell of the static mixer, which contains the internal mixing elements. It is designed to withstand the pressure and temperature of the fluid stream. The housing can be cylindrical, rectangular, or custom-shaped to fit specific applications.

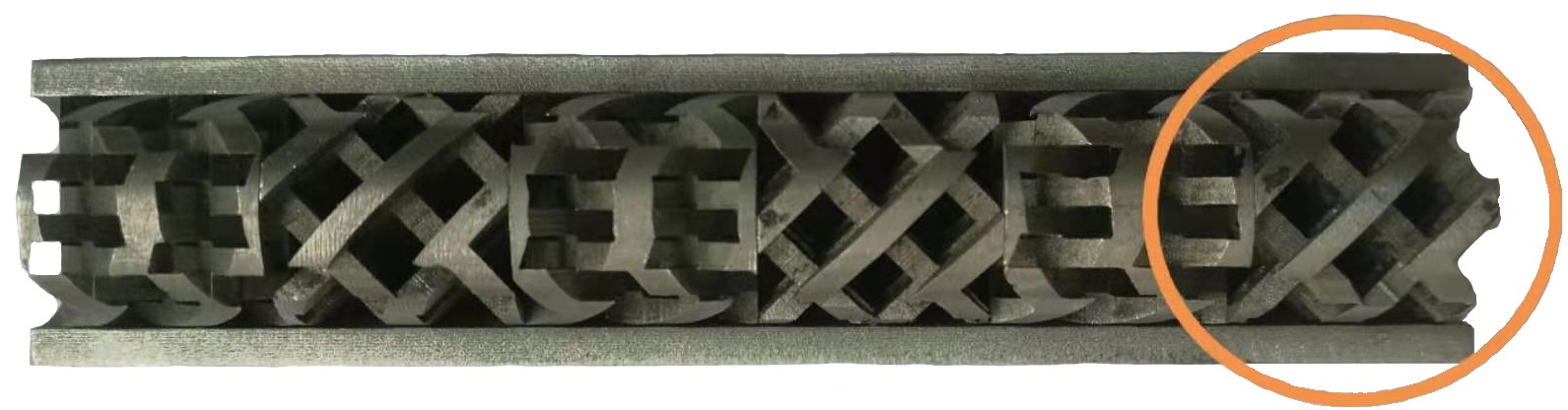

Mixing Elements

The mixing elements are the heart of the static mixer. These elements are designed to create turbulence and promote mixing. They can take various forms, including helical, corrugated, or grid-like structures. The design and arrangement of the mixing elements are optimized for the specific mixing requirements of the application.

End Connections of Static Mixers

Static mixers are equipped with end connections that allow them to be integrated into the piping system. These connections can be flanged, threaded, or welded, depending on the installation requirements.

Operation of Static Mixers

The operation of a static mixer is straightforward and requires no external power source. As the fluid streams enter the mixer, they are directed through the internal mixing elements. In addition, the design of these elements ensures that the fluids are divided, recombined, and subjected to radial mixing. The fluids continue to mix as they pass through each stage of the mixer, resulting in a homogeneous mixture at the outlet.

Conclusion

Static mixers are essential tools for achieving efficient and consistent mixing in a wide range of industrial applications. Moreover, their simple design, lack of moving parts, and energy efficiency make them a popular choice in many industries. In addition, while they have some limitations, such as pressure drop and limited adjustability, their advantages often outweigh these drawbacks. Finally, proper selection, installation, and maintenance of static mixers ensure reliable and long-term performance, contributing to the overall efficiency and effectiveness of industrial processes.

Specifications

Installation

Installation Procedures for a Static Mixer with Various Connection Ends

Preparation

Safety First:

- Ensure that the installation site is safe and that all necessary personal protective equipment (PPE) is worn.

- Verify that the system is depressurized and drained before starting the installation.

Verify Components:

- Check that you have the correct static mixer model and all necessary components, including the appropriate connection ends (MNPT threaded, flanged, or Tri clamp sanitary).

- Inspect the static mixer and connection ends for any damage or defects.

Gather Tools and Materials:

- Wrenches, gaskets, bolts, nuts, sealants, and other tools specific to the type of connection end being installed.

Installation Procedures

MNPT Threaded Connection

Step 1: Prepare the Threaded Ends

- Ensure that the threaded ends of both the static mixer and the piping are clean and free of debris.

- Apply an appropriate thread sealant or Teflon tape to the male threads of the mixer to ensure a leak-free connection.

Step 2: Align the Mixer

- Align the static mixer with the piping system, ensuring that the flow direction marked on the mixer matches the intended flow direction in the system.

Step 3: Thread the Mixer

- Hand-tighten the mixer into the female threaded connection on the piping system.

- Use a pipe wrench to tighten the connection further, ensuring not to over-tighten as this could damage the threads.

Step 4: Secure the Connection

- Ensure that the mixer is securely fastened and there are no visible gaps or misalignments in the connection.

Step 5: Check for Leaks

- Once installed, gradually pressurize the system and check for leaks around the threaded connections.

- If leaks are detected, depressurize the system and re-tighten the connections as necessary.

Flanged Connection

Step 1: Prepare the Flanges

- Ensure that the flanged ends of both the static mixer and the piping are clean and free of debris.

- Place a gasket between the flanges to ensure a proper seal.

Step 2: Align the Mixer

- Align the flanges of the static mixer with those on the piping system, ensuring the flow direction marked on the mixer matches the intended flow direction in the system.

Step 3: Insert Bolts

- Insert bolts through the aligned flanges and hand-tighten the nuts to hold the mixer in place.

Step 4: Tighten the Bolts

- Use a torque wrench to tighten the bolts in a crisscross pattern to ensure even pressure distribution and a secure seal.

- Follow the recommended torque specifications for the bolts to avoid over-tightening and damaging the flanges or gasket.

Step 5: Check for Leaks

- Gradually pressurize the system and check for leaks around the flanged connections.

- If leaks are detected, depressurize the system and re-tighten the bolts as necessary.

Tri clamp Sanitary Connection

Step 1: Prepare the Clamp Ends

- Ensure that the Tri clamp ends of both the static mixer and the piping are clean and free of debris.

- Place a sanitary gasket between the clamp ends to ensure a proper seal.

Step 2: Align the Mixer

- Align the Tri clamp ends of the static mixer with those on the piping system, ensuring the flow direction marked on the mixer matches the intended flow direction in the system.

Step 3: Position the Clamp

- Position the Tri clamp around the aligned ends and ensure that the gasket is properly seated between the connection points.

Step 4: Secure the Clamp

- Hand-tighten the clamp to hold the mixer in place.

- Use a clamp tool to secure the connection, ensuring even pressure and a tight seal.

Step 5: Check for Leaks

- Gradually pressurize the system and check for leaks around the Tri clamp connections.

- If leaks are detected, depressurize the system and re-secure the clamp as necessary.

Post-Installation

System Testing:

- After installing the static mixer, perform a thorough system test to ensure proper operation and no leaks.

- Gradually increase the system pressure and flow rate to operational levels, monitoring for any issues.

Documentation:

- Record the installation details, including the date, personnel involved, and any observations or adjustments made during the process.

Maintenance Plan:

- Establish a maintenance plan for periodic inspection and cleaning of the static mixer to ensure long-term performance and reliability.

By following these detailed installation procedures for MNPT threaded, flanged, and Tri clamp sanitary connections, you can ensure a secure and efficient installation of your static mixer, contributing to optimal mixing performance in your system.

Maintenance

Maintenance Procedures for Static Mixers

Maintaining static mixers is crucial for ensuring their optimal performance and longevity. Here are detailed maintenance procedures to keep your static mixers in excellent working condition.

1. Routine Inspection

Frequency: Monthly or as recommended by the manufacturer.

Procedure:

- Visual Inspection:

- Check for any visible signs of wear, corrosion, or damage on the mixer housing and connections.

- Inspect the piping connections for any leaks or loose fittings.

- Operational Check:

- Ensure that there are no unusual noises or vibrations during operation.

- Verify that the flow rates and pressures are within the specified range.

- Check for any blockages or flow irregularities.

2. Cleaning

Frequency: Quarterly or as needed, depending on the application and fluid properties.

Procedure:

- System Flush:

- Flush the system with a compatible cleaning solution to remove any buildup of residues or contaminants.

- Ensure that the cleaning solution is circulated through the static mixer for a sufficient period to dislodge and remove any deposits.

- Disassembly (if needed):

- For thorough cleaning, disassemble the static mixer according to the manufacturer’s instructions.

- Remove the internal mixing elements and clean them using a soft brush or appropriate cleaning agents.

- Rinse all components thoroughly with clean water and ensure they are completely dry before reassembly.

3. Internal Inspection

Frequency: Semi-annually or annually.

Procedure:

- Disassembly:

- Depressurize the system and drain any residual fluids before disassembling the static mixer.

- Follow the manufacturer’s guidelines to safely remove the mixer from the piping system.

- Inspect Mixing Elements:

- Check the internal mixing elements for signs of wear, erosion, or damage.

- Ensure that the elements are securely attached and properly aligned.

- Inspect Housing:

- Examine the internal surfaces of the mixer housing for any signs of corrosion or pitting.

- Clean and repair any minor damage to prevent further deterioration.

4. Gasket and Seal Replacement

Frequency: Annually or as needed based on inspection results.

Procedure:

- Inspect Gaskets and Seals:

- During disassembly, check all gaskets and seals for signs of wear, cracking, or deformation.

- Replace as Necessary:

- Replace any damaged or worn gaskets and seals with new ones, ensuring they are compatible with the fluids being processed.

- Reassembly:

- Reassemble the static mixer, ensuring that all seals and gaskets are properly seated and secured.

5. Calibration and Performance Testing

Frequency: Annually or as part of a scheduled maintenance program.

Procedure:

- Flow Rate Verification:

- Measure and verify the flow rates through the static mixer to ensure they are within the specified range.

- Pressure Drop Check:

- Check the pressure drop across the static mixer and compare it with the manufacturer’s specifications.

- Significant deviations may indicate blockages or wear in the mixing elements.

- Mixing Efficiency:

- Conduct tests to verify the mixing efficiency, ensuring that the desired level of homogeneity is achieved.

- Adjust flow rates or replace mixing elements if necessary to maintain optimal performance.

6. Documentation

Frequency: Ongoing, as part of every maintenance activity.

Procedure:

- Maintenance Logs:

- Maintain detailed records of all maintenance activities, including inspections, cleanings, repairs, and replacements.

- Performance Records:

- Document any performance tests and results, noting any deviations from expected performance.

- Component History:

- Keep a history of all replaced components, including the dates of replacement and any observations.

7. Emergency Procedures

Frequency: As needed, in response to system alerts or failures.

Procedure:

- Immediate Inspection:

- In the event of a system alert or failure, perform an immediate inspection to identify the issue.

- Troubleshooting:

- Follow troubleshooting guidelines to diagnose and rectify the problem. This may involve cleaning blockages, tightening connections, or replacing damaged components.

- System Restart:

- After resolving the issue, gradually restart the system and monitor for any further problems.

8. Spare Parts Management

Frequency: Ongoing, as part of inventory management.

Procedure:

Inventory Check:

- Regularly check the inventory of spare parts, including gaskets, seals, and mixing elements.

Stock Replenishment:

- Ensure that spare parts are reordered and stocked to avoid downtime during maintenance or emergency repairs.

Conclusion

Regular maintenance of static mixers is essential to ensure their efficiency and longevity. By following these detailed procedures for routine inspection, cleaning, internal inspection, gasket and seal replacement, calibration and performance testing, documentation, emergency procedures, and spare parts management, you can maintain optimal performance and reliability of your static mixers in various industrial applications.

Applications

Applications

Static mixers are used in a wide range of applications across various industries. Some common applications include:

Chemical Processing

In the chemical industry, static mixers are used to mix reactants, dilute concentrated solutions, and blend additives. They ensure a consistent and uniform mixture, which is critical for chemical reactions and product quality.

Water and Wastewater Treatment

Static mixers are widely used in water and wastewater treatment plants for applications such as chemical dosing, pH adjustment, and coagulant mixing. They provide efficient and reliable mixing, which is essential for effective treatment processes.

Oil and Gas

In the oil and gas industry, static mixers are used for blending different grades of crude oil, mixing additives, and emulsifying water and oil. They help to improve the efficiency of downstream processes and ensure product consistency.

Food and Beverage

The food and beverage industry uses static mixers for applications such as blending ingredients, homogenizing liquids, and mixing flavorings. They provide gentle and consistent mixing, which is important for maintaining product quality and texture.

Pharmaceuticals

In pharmaceutical manufacturing, static mixers are used to mix active ingredients, solvents, and excipients. They ensure a uniform mixture, which is critical for the efficacy and safety of pharmaceutical products.

Advantages / Disadvantages

Advantages

Static mixers offer several advantages over other types of mixing equipment:

No Moving Parts

Static mixers have no moving parts, which means they require minimal maintenance and have a long operational life. This also reduces the risk of mechanical failure and downtime.

Energy Efficiency

Since static mixers rely on the flow of the fluid to achieve mixing, they do not require an external power source. This makes them highly energy-efficient and cost-effective to operate.

Consistent Mixing

Static mixers provide consistent and uniform mixing, which is essential for many industrial processes. Their design ensures that the fluid components are evenly distributed, resulting in a homogeneous mixture.

Compact Design

Static mixers have a compact design, which makes them easy to install in existing piping systems. They can be used in confined spaces and do not require additional infrastructure.

Versatility

Static mixers can handle a wide range of fluid types and mixing requirements. They can be used for liquids, gases, and multiphase flows, making them versatile for different applications.

Disadvantages

While static mixers offer many benefits, they also have some limitations:

Pressure Drop

The internal elements of a static mixer create a pressure drop as the fluid passes through the mixer. This pressure drop can be significant, especially in high-viscosity fluids or high-flow applications. It is important to consider this factor when designing the system.

Limited Adjustability

Once a static mixer is installed, its mixing performance cannot be easily adjusted. Unlike mechanical mixers, which can be adjusted to change the mixing intensity, static mixers have a fixed design. This can be a limitation if the mixing requirements change.

Potential for Fouling

In applications involving particulate matter or viscous fluids, there is a risk of fouling and clogging of the internal elements. Regular cleaning and maintenance may be required to ensure optimal performance.

Downloads

Drawings

Q&A

Only logged in customers who have purchased this product may leave a review.

Static mixers are devices designed to mix fluids without moving parts. They are commonly used in various industries, including chemical processing, water and wastewater treatment, oil and gas, food and beverage, and pharmaceuticals. In addition, the primary function of static mixers is to blend two or more fluid streams into a homogeneous mixture. They achieve this by using a series of carefully designed internal elements that induce turbulence and promote mixing as the fluids pass through the mixer. Finally, this detailed overview will cover the principles, construction, operation, applications, advantages, and disadvantages of static mixers.

Static mixers are devices designed to mix fluids without moving parts. They are commonly used in various industries, including chemical processing, water and wastewater treatment, oil and gas, food and beverage, and pharmaceuticals. In addition, the primary function of static mixers is to blend two or more fluid streams into a homogeneous mixture. They achieve this by using a series of carefully designed internal elements that induce turbulence and promote mixing as the fluids pass through the mixer. Finally, this detailed overview will cover the principles, construction, operation, applications, advantages, and disadvantages of static mixers.

Reviews

There are no reviews yet.