Description

A Thermal Mass Flow Meter is suitable for all industrial and test platform applications that require fast, accurate gas measurement. Moreover, the flowmeter directly indicates the mass flow or standardized volume flow of the gas without any additional pressure and temperature compensation. Additionally, they have impressive high accuracy, short response times, and a very wide flow range, with almost no loss of accuracy even at the lowest flow.

A thermal mass flowmeter is an instrument used to measure the flow rate of a fluid, such as gases or liquids, by utilizing the principle of thermal conduction. It is widely used in various industries, including chemical, oil and gas, pharmaceutical, and food and beverage, because of its accuracy, reliability, and versatility.

Working Principle of a Thermal Mass Flow Meter

The basic working principle of a thermal mass flow meter involves the measurement of the cooling effect of a flowing fluid on a heated sensor element. The sensor element consists of two temperature sensors: a heated sensor and a reference sensor. The heated sensor is maintained at a constant temperature higher than the fluid temperature, while the reference sensor is kept at the fluid temperature. As the fluid flows through the flowmeter, it conducts heat away from the heated sensor, resulting in a temperature difference between the two sensors.

The magnitude of this temperature difference is directly proportional to the mass flow rate of the fluid. The thermal mass flow meter measures this temperature difference and calculates the mass flow rate using a heat transfer equation. By measuring the thermal conductivity and specific heat capacity of the fluid, the flowmeter provides an accurate measurement of the mass flow rate.

Different Types of a Thermal Mass Flow Meter

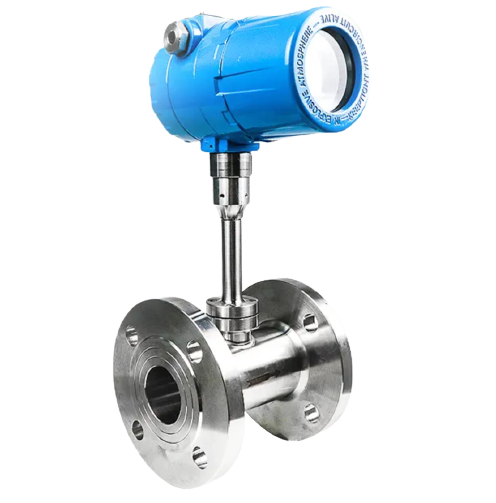

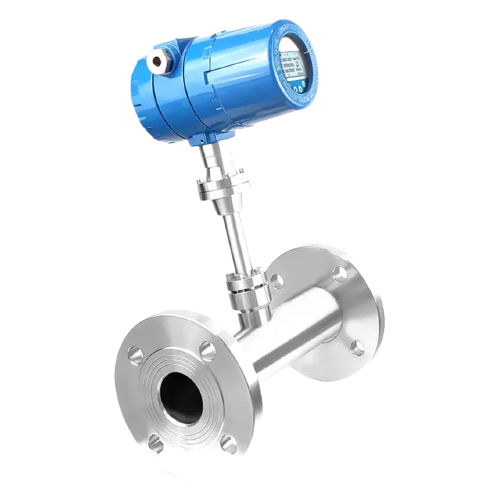

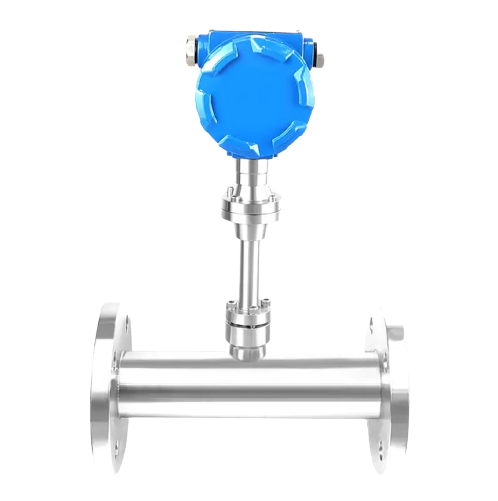

There are different types of thermal mass flowmeters available in the market. One common design is the insertion-type flowmeter, where the sensor element is inserted into the flow stream through a probe. This type of flowmeter is suitable for large pipe sizes and high flow rates.

Another design is the inline-type flowmeter, where the sensor element is directly installed in the flow line. This type of flowmeter is compact, easy to install, and suitable for a wide range of pipe sizes. It is commonly used for measuring gases and compressed air.

Thermal mass flowmeters offer several advantages over other flow measurement technologies. Firstly, they have no moving parts, which means they are less prone to mechanical wear, reducing maintenance requirements. Secondly, they have a wide turndown ratio, allowing accurate measurements over a broad range of flow rates.

Limitations

Additionally, they have a fast response time, enabling real-time measurement and control.

Thermal mass flowmeters also have some limitations that need to be considered. They are generally not suitable for measuring fluids with high viscosity or low thermal conductivity, as they may affect the accuracy of the measurement. Furthermore, they are sensitive to changes in fluid composition, so it is important to ensure that the fluid characteristics are within the flowmeter’s specified range.

In conclusion, a thermal mass flowmeter is a versatile instrument used to measure the flow rate of fluids in various industries. Its principle of operation based on thermal conduction provides accurate and reliable measurements. With no moving parts, a wide turndown ratio, and fast response time, thermal mass flowmeters are an ideal choice for applications requiring precise and real-time flow measurements.

Features and Benefits of a Thermal Mass Flow Meter

Wide Range of Applications: The Thermal mass flow meter can be deployed in a wide range of applications, including general process control, gas consumption monitoring, air and gas flow monitoring in HVAC systems, and environmental monitoring.

High Accuracy and Repeatability for a Thermal Mass Flow Meter: Thermal mass flow meters are known for their high level of accuracy and repeatability in measuring flow rates. Moreover, this accuracy is maintained across a wide range of flow rates, making them reliable for both low and high flow conditions.

Multi-Fluid Capability: Many thermal mass flow meters are designed to measure the flow rates of different gases or liquids. Additionally, they can be calibrated for specific fluid properties. This allows for accurate measurements across various fluids with different thermal conductivities and specific heat capacities.

Wide Turndown Ratio: The Thermal mass flow meter offers a wide turndown ratio, which means it can accurately measure flow rates from extremely low to very high velocities. Also, this flexibility enables them to handle varying flow conditions without compromising measurement accuracy.

Real-Time Measurement and Response: Thermal mass flowmeters provide real-time flow rate measurements, allowing for immediate process adjustments and control. They have a fast response time, making them suitable for applications that require quick monitoring and adjustment.

Minimal Pressure Drop: Thermal mass flowmeters have a minimal pressure drop compared to other flow measurement technologies. This ensures that the flow characteristics of the system being measured are not significantly affected. Also, minimizing any potential disruption to the overall process.

Easy Installation and Maintenance

Thermal mass flowmeters are relatively simple to install and require minimal maintenance. With no moving parts, fewer components can wear or malfunction, reducing the need for regular maintenance and decreasing the risk of breakdowns.

Digital Communication and Integration: Many modern thermal mass flowmeters come equipped with digital communication protocols such as Modbus, HART, or Foundation Fieldbus. This allows for seamless integration with control systems, enabling remote monitoring. It also allows data logging and easy integration within an industrial network.

Compact and Lightweight Design: Thermal mass flowmeters are generally compact and lightweight, offering ease of installation. Additionally, it adds flexibility in various piping systems or field locations.

Cost-Effective Solution: Thermal mass flowmeters are often considered a cost-effective flow measurement solution. This is due to their accuracy, low maintenance requirements, and long-term reliability. Their ability to provide precise flow measurements helps optimize processes. This will reduce wastage, resulting in cost savings over time.

In summary, thermal mass flowmeters offer high accuracy, multi-fluid capability, and real-time flow rate measurement. With their wide turndown ratio, minimal pressure drop, easy installation, and digital communication capabilities. Considering this, they provide a reliable and cost-effective solution for diverse flow measurement applications across different industries.

Product introduction

A Thermal Mass Flow Meter is suitable for all industrial and test rig applications. This demands quick and precise gas measurement. Also, the Flow Meters directly indicate the mass flow or normalized volume flow of gases. This is without any additional pressure and temperature compensation. Finally, they have impressively high accuracy, short response time, and a very wide flow range. This happens with virtually no loss of accuracy even at the lowest flow rates.

Touch screen transmitter: We have our patented touchscreen transmitters with DSP core processors with faster data processing speed.

Insertion Type; Pipeline Type: For the pipeline size below DN65, it is recommended to use the pipeline type. Moreover, for the pipeline size higher than DN65, it is recommended to use the insertion type.

Output: Also, 4-20mA, Standard RS 485 communication protocol, and HART Protocol

Connections: The connections can be customized, including flanges, threaded connections, etc. Furthermore, we will also include the ball head along with the thermal flow meters.

Circuit: We are providing the new generation of DSP transmitters with faster data processing.

Sensor: Finally, the sensor of thermal mass flow meters includes two sensors. One is to heat the air, and the other one is to sense the heat taken away by the flow of air.

If you are looking for questions and answers?

Specifications

Specifications

- Direct measurement of gas mass flow without any temperature or pressure compensation

- ± 1.0% high accuracy, fast response time, and very wide flow range. In addition, even at the lower limit of the flow range, the accuracy is still very good.

- Applications: Industrial plants, oil, and gas upstream and downstream production, water and wastewater treatment plants, etc.

Enclosure Certifications by manufacturer

CSA – CL. I. GR. A, B, C, D; CL. II. GR. E, F, G; CL. III.;TYPE 4X

US – CL. I. GR. A, B, C, D; CL. II. GR. E, F, G; CL. III.;TYPE 4X

IECEx – Ex d IIC Gb, Ex t IIIC Db,

ATEX – II 2G Ex IIC Gb, II 2Dd Ex t 111C Db

Linear signal output: 0–5 VDC & 4–20 mA (Flow and Temperature)

Event Relay Rating one with Frequency or two, 1 Amp @ 30Vdc (33W)

Signal Interface: RS232 & RS485 Modbus RTU embedded, Optional HART or Profibus DP, LCD (flow rate, flow total, gas temperature)

Accuracy, including linearity (Ref.: 21°C): ±(1% of Reading + 0.5% of Full Scale + GTC)

Repeatability: ±0.2% of Full Scale

Sensor response time: 1 second to 63% of final value

Turn down ratio: 100:1 @ 10 SFPM (.051 NMPS) Minimum Reading

Electronics PCB temperature range: -40° to 158°F (-40° to +70°C)

Environmental temperature range: -40° to 140°F (-40° to +60°C)

Gas temperature range: -40°–392°F (-40°–200°C)

Gas temperature coefficient (GTC): 0.02% Full Scale/°C

Gas pressure effect: Negligible over ± 20% of absolute calibration pressure

Pressure rating maximum: 500 PSI Std.

Input power requirement: 24VDC @ 250mA, 115 VAC 50/60 Hz optional, 230 VAC 50/60 Hz optional

Flow Transmitter power requirements: 5 watts maximum

RAM Back-up: Lithium Battery

Wetted materials: 316 Stainless Steel (Hastelloy optional)

Standard temperature & pressure (STP): 70°F & 29.92″ Hg (Air .075 lb./cubic foot)

NIST traceable calibration: Standard

NOTE: Specifications are subject to change without notice.

| Performance |

Technical Parameters |

| Struct |

Plug-in |

Pipeline |

| Media |

Various gases (except acetylene gas) |

| Pipe Range |

DN100~2000mm |

DN15~300mm |

| Flow range |

0.1~120Nm/s |

| Accuracy |

±1~2.5% |

| Temp |

Sensor:-40~+160°C ,Convertor: -20~+45°C |

| Pressure |

Media Pressure≤2.5MPa |

| Power |

DC24VorAC220V≤18W |

| Reaction |

1s |

| Output |

4-20mA、Pulse、RS-485、HART |

| Alarm |

2relay(keep open)、10A/220VAC、5A/24VDC |

| Display type |

Carbon steel, stainless steel, plastic, etc. |

| Material |

M20X1.5;NPT1/2 |

| Display |

LCD |

| Contents |

Mass flow, volume flow, cumulative flow, time, running time, standard flow rate |

| Protect |

IP65 |

| Sensor |

Stainless steel, carbon steel |

Q&A

A Q&A Thermal Mass Flow Meters, which stands for “question and answer for Thermal Mass Flow Meters,” is a format commonly used to facilitate communication and exchange of information. In a Q&A Thermal Mass Flow Meters, one person asks a question, and another person or group provides an answer or response to that question. This format is widely used in various contexts, such as interviews, discussions, presentations, or online forums. It allows for a structured and organized way of addressing inquiries and obtaining relevant information. Is there anything specific you would like to know about Q&A Thermal Mass Flow Meters?

Q: What is a thermal mass flow meter?

A: A thermal Mass flow meter is a type of flow meter that measures the flow of fluids based on the rate at which heat is transferred from a heated object to the flowing fluid. The meter typically consists of a heated element and one or more temperature sensors that measure the temperature of the fluid as it flows past the element.

Q: What are the advantages of using a thermal flow meter?

A: The advantages of using a thermal mass flow meter include high accuracy, wide rangeability, and low-pressure drop. Thermal flow meters are also insensitive to changes in fluid properties such as viscosity or density, making them ideal for use with a wide range of fluids.

Q: What types of fluids can be measured with thermal flow meters?

A: Thermal Mass flow meters can be used to measure the flow of a wide range of fluids. The range includes liquids, gases, and steam. Some meters are designed specifically for use with certain types of fluids, while others are more versatile and can be used with a variety of fluids.

Q: How accurate are thermal flow meters?

A: The accuracy of thermal mass flow meters depends on several factors. This includes the specific meter and the conditions in which it is used. In general, thermal flow meters are highly accurate and can provide precise measurements even in challenging environments. Accuracy can be affected by factors such as changes in fluid temperature, pressure, or composition.

Q: What is the range of a thermal mass flow meter?

A: The range of a thermal flow meter depends on the specific meter and the conditions in which it is used. Some meters have a range of just a few feet, while others can measure flows over long distances. In general, the range of a thermal flow meter can be extended by using additional sensors or signal boosters.

Q: What is the installation process for a thermal flow meter?

A: The installation process for a thermal flow meter varies depending on the specific meter and the system being measured. In general, the meter must be placed in a location where it can accurately measure the flow of fluid. It would also need to be connected to the control system or data logger. Some thermal mass flow meters are designed to be easy to install and can be set up in just a few minutes. May other meters require more extensive installation and configuration.

Q: What is the maintenance required for a thermal flow meter?

A: The maintenance required for a thermal flow meter depends on the specific meter and the environment in which it is used. In general, thermal mass flow meters require minimal maintenance. They have no moving parts that can wear out or require lubrication. However, regular calibration and cleaning of the meter may be necessary to ensure accurate measurements.

Q: Can thermal mass flow meters be used in hazardous environments?

A: Yes, thermal flow meters can be used in hazardous environments as long as they are designed and certified for use in such environments. In these cases, the meters may need to meet specific safety standards. They may also need to be designed to operate in environments with potentially explosive gases or other hazardous materials.

Q: Can mass flow meters be used in high-temperature applications?

A: Yes, mass flow meters can be used in high-temperature applications. However, the specific meter must be designed to withstand the high temperatures and thermal stresses associated with these applications. Some thermal mass flow meters are designed to measure the flow of hot gases, while others are designed for use with high-temperature liquids or steam.

Q: What are some common applications for thermal flow meters?

A: Thermal flow meters are commonly used in a variety of industrial and commercial applications. They are often used in chemical processing, power generation, food and beverage production, and HVAC systems. They can also be used in research and development applications to measure the flow of gases or liquids in laboratory experiments.

Q: What factors should be considered when selecting a thermal flow meter?

A: When selecting a thermal flow meter, several factors should be considered, including the specific application. It should also consider the type of fluid being measured, the flow rate and range, and the required accuracy. Other factors to consider include the operating temperature and pressure range. Another factor is the type of output signal required, and the installation and maintenance requirements.

Q: How do thermal flow meters compare to other types of flow meters?

A: Thermal mass meters offer several advantages over other types of flow meters, including high accuracy, wide rangeability, and low-pressure drop. They are also well-suited for measuring the flow of gases, liquids, and steam. It is also insensitive to changes in fluid properties such as viscosity or density. However, they may not be suitable for use in applications where the fluid is opaque or contains suspended particles. The reason is that these can interfere with the measurement of heat transfer.

Buy

Thermal Mass Flow Meters

Advantages / Disadvantages

Thermal mass flow meters have several advantages and disadvantages. Here are some key points:

Advantages

High Accuracy: Thermal mass flow meters are known for their high accuracy in measuring gas flow rates.

Wide Rangeability: These meters can measure a wide range of flow rates, from very low to very high.

Direct Mass Flow Measurement: Unlike volumetric flow meters, thermal mass flow meters directly measure mass flow rate, making them unaffected by changes in temperature and pressure.

Low-Pressure Drop: Thermal mass flow meters typically have a low-pressure drop, which minimizes the impact on the system being measured.

Disadvantages

Cost: Thermal mass flow meters can be more expensive upfront compared to some other types of flow meters.

Limited Applicability: They are typically used for gas flow measurement and may not be suitable for all types of fluids.

Response Time: Some thermal mass flow meters may have slower response times compared to other types of flow meters.

Installation Requirements: Proper installation and calibration are crucial for accurate measurements, which may require additional time and expertise.

These are just some general advantages and disadvantages of thermal mass flow meters. For specific applications and requirements, it’s always recommended to consult with a flow measurement specialist to determine the best option.

Applications

Applications

Thermal mass flowmeters are commonly used in a variety of applications where accurate and reliable flow measurements are required. Some of the key industries that extensively utilize thermal mass flowmeters include:

Chemical Industry

In chemical manufacturing processes, thermal mass flowmeters are used for measuring the flow rates of various gases and liquids. They play a crucial role in controlling and optimizing the dosing of chemicals, maintaining consistent production quality, and ensuring safe operations.

Oil and Gas Industry

mass flowmeters are widely employed in the oil and gas sector for monitoring gas flows in pipelines, measuring flare gas emissions, quantifying fuel consumption, and controlling the distribution of natural gas. They help in detecting leakages, optimizing energy usage, and ensuring compliance with environmental regulations.

Pharmaceutical Industry

In pharmaceutical production, precise measurement of different gases and liquids is vital for the success of manufacturing processes. Thermal mass flowmeters are used for monitoring and controlling the flow of compressed air, nitrogen, carbon dioxide, and other process gases, ensuring efficiency and quality in pharmaceutical operations.

Food and Beverage Industry

Thermal mass flowmeters find application in the food and beverage sector for measuring the flow rates of gases such as carbon dioxide used in carbonation processes, as well as for monitoring the flow of liquids like water, milk, fruit juices, and beverages. Accurate flow measurement is essential to control ingredient proportions and maintain product consistency.

HVAC and Building Automation

Heating, ventilation, and air conditioning (HVAC) systems rely on thermal mass flowmeters for measuring the flow of air and other gases. These flowmeters help in optimizing energy consumption, monitoring indoor air quality, and regulating temperature and humidity levels in commercial and residential buildings.

Environmental Monitoring

Thermal mass flowmeters play a role in environmental monitoring applications, such as measuring gas emissions from industrial processes, stack gases, or exhaust gases from vehicles. They assist in determining compliance with emission regulations and assessing air quality.

It is important to note that the specific design and features of thermal mass flowmeters can vary based on the application requirements. Moreover, it factors such as fluid properties, desired measurement range, and installation considerations. Additionally, they have certifications for use in hazardous environments might influence the selection of a suitable thermal mass flowmeter.

Overall, thermal mass flowmeters have become an integral part of various industries, offering accurate and reliable flow measurements. Their versatility, ease of installation, and low maintenance requirements make them an ideal choice for applications where precise flow control and monitoring are critical.

Reviews

There are no reviews yet.