Description

Micro Mass Flow Meter: A Comprehensive Overview

A micro mass flow meter is a highly specialized instrument designed to measure the mass flow rate of very small volumes of fluids, often at the microliter per minute to milliliter per minute scale. In addition, these devices are crucial in applications requiring precise flow measurement of tiny fluid quantities, such as in microfluidics, pharmaceuticals, biotechnology, and advanced manufacturing processes. Finally, this detailed exploration covers the principles of operation, types, components, applications, advantages, limitations, and maintenance of micro mass flow meters.

Principles of Operation

Micro mass flow meters operate on the principle of measuring the mass flow rate of a fluid rather than its volumetric flow rate. Unlike volumetric flow meters, which measure the volume of fluid passing through a given point, mass flow meters directly measure the mass of the fluid, providing a more accurate representation of the actual quantity of fluid moving through the system. Finally, this is particularly important in applications where the fluid’s density can vary, as density changes do not affect mass flow measurements.

Mass flow meters achieve this by utilizing various technologies, including thermal, Coriolis, and micro-machined sensors. Moreover, each technology has its unique method for determining the mass flow rate:

Thermal Flow Meters: These meters measure the heat dissipation in the fluid flow. They typically consist of a heated element and temperature sensors. In addition, as fluid flows over the heated element, it absorbs some of the heat, and the temperature sensors detect the changes. Furthermore, the rate of heat dissipation correlates with the mass flow rate of the fluid. Finally, we often use thermal mass flow meters for gases, but we can adapt them for liquids in specific applications.

Coriolis Flow Meters: Coriolis meters utilize the Coriolis effect, where the flow of fluid through vibrating tubes creates a phase shift in the vibration frequency. This shift is proportional to the mass flow rate of the fluid. Coriolis meters are highly accurate and suitable for measuring both liquids and gases.

Micro-Machined Sensors: Micro mass flow meters use micro-machined sensors, such as those based on silicon or other materials, to measure fluid flow with high precision. These sensors often integrate multiple measurement techniques to ensure accuracy and reliability in small-scale applications.

Types of Micro Mass Flow Meters

Micro mass flow meters come in several types, each designed to meet specific needs based on the measurement principle and application requirements:

Thermal Micro Mass Flow Meters: Engineers design these meters for precise flow measurement of small quantities of gases and liquids. They are ideal for applications requiring high sensitivity and fast response times. Researchers and engineers often use thermal meters in laboratory experiments, chemical analysis, and medical devices.

Coriolis Micro Mass Flow Meters: These meters provide high accuracy and are suitable for applications involving both gases and liquids. Coriolis meters are valued for their ability to measure mass flow rate directly and handle varying fluid properties. Chemical processing, pharmaceuticals, and precision manufacturing commonly use them.

Micro-Machined Flow Meters: These are fabricated using micro-electromechanical systems (MEMS) technology. They are designed for ultra-low flow rates and are used in applications such as microfluidics, diagnostics, and research. We know micro-machined meters for their compact size, high precision, and ability to operate in small-scale environments.

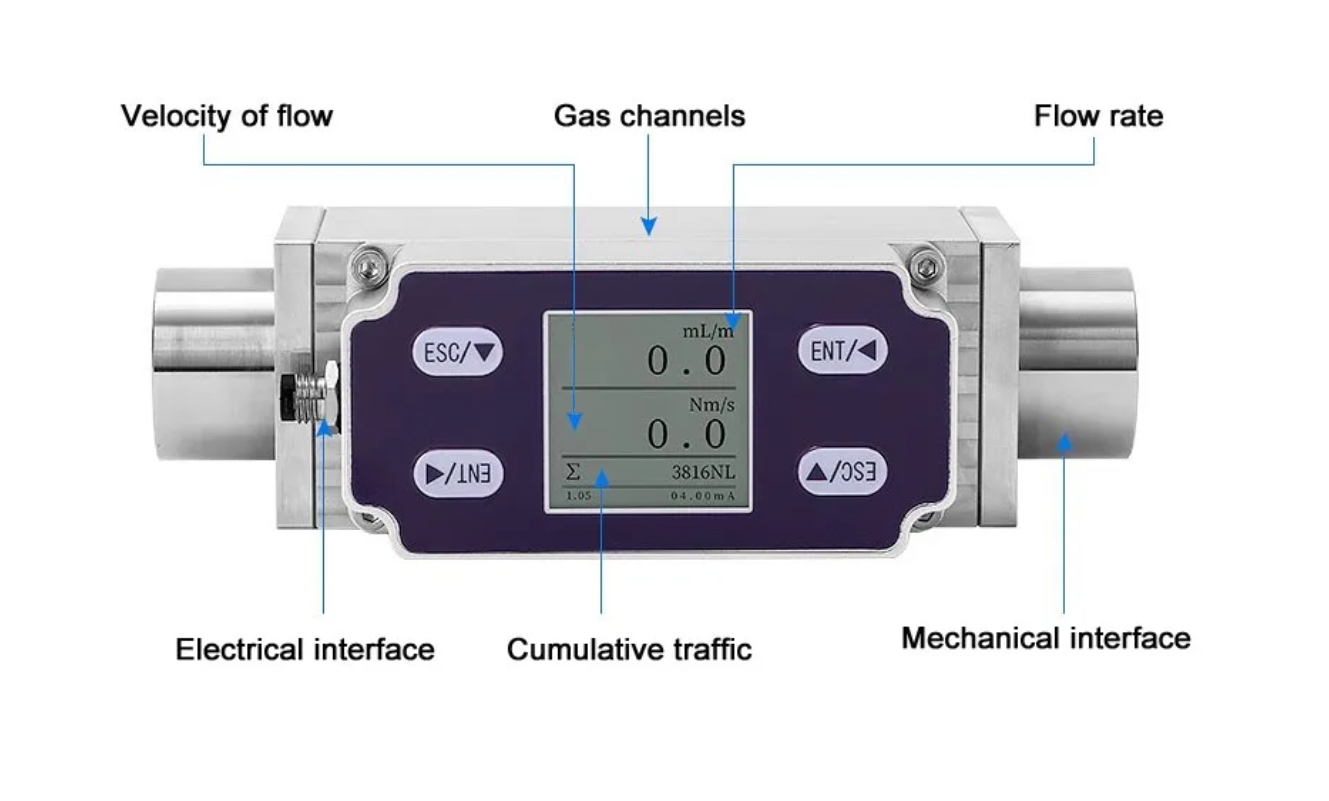

Components of a Micro Mass Flow Meter

Sensor Element: The core component of the micro mass flow meter, responsible for detecting the flow of fluid. Depending on the technology, this could be a heated element, vibrating tube, or micro-machined sensor.

Transmitter: Processes signals from the sensor element and converts them into a readable mass flow rate measurement. The transmitter may also handle additional functions such as temperature compensation and data output.

Display Unit: Provides a visual readout of the flow rate. You can integrate this into the meter or incorporate it into a larger control system interface. Advanced display units may offer features such as trend analysis and historical data logging.

Flow Conditioning Elements: Some micro mass flow meters include flow conditioning elements, such as filters or straightening vanes. This ensures a consistent flow profile and accurate measurement.

Housing and Connections: The housing protects the internal components and provides the necessary connections for integrating the flow meter. This can be done into the pipeline or system. The connections must be secure to prevent leaks and ensure accurate measurements.

Conclusion

A micro mass flow meter is a critical tool for accurately measuring very small quantities of fluids. It will measure it in various industrial, scientific, and medical applications. Also, by understanding the principles of operation, types, components, applications, advantages, and limitations of these meters, users can effectively utilize them to enhance process control. This will ensure product quality and support advanced research and development. Finally, proper installation, maintenance, and calibration are essential to maximize the performance. It will also maximize reliability of micro mass flow meters in demanding applications.

Specifications

Featuring:

- Measure and control flow rates down to 0.1 sccm (smlm)

- Increase efficiency with true, digital high-performance.

- Navigate easily with a large multifunction display interface.

- Save time by adjusting in the field.

- Configure up to 10 gases with one instrument.

Industries: General Research / Analytical / Life Sciences & Health / Biopharmaceutical / Life Science / Medical Devices

Thermal Mass Gas Flow Meter with Valve Option

Suitable for a variety of Dry, Clean Gases (User Configurable)

DN6, 0 – 20 SLPM (42.38 SCFH, 1.20 NCMH)

Hi/Low Alarm configuration (Visual & Audible alert)

1/4″ BSP (or NPT)

Thermal Mass Flow Measurement,

RS485 Modbus RTU output option

Integrated Valve option

4x AA Batteries or USB Type-C Powered

- Accuracy ±(2.0+0.5FS) %

- Repeatability 0.5 %

- Turn-down ratio 80:1

- Response time

- Working temperature -10~55 °C

- Maximum pressure 0.8 MPa (8 Bar)

- Humidity <95%RH noncondensing

- Maximum overflow MF5706=100 MF5708=200 MF5712=400 L/min

- Maximum flow change MF5706=15 MF5708=30 MF5712=60 L/min

- Pressure loss MF5706=0.6 MF5708=1.0 MF5712=2.0 kPa

- Power supply 4-AA batteries (LR6) / 5~24 Vdc

- Power consumption >60 (on batteries) per day

- Power/data interface USB Type-C

- Digital RS485 Modbus half-duplex

- Wireless options LoRa / WIFI / NB-IoT / BT LE Display

- LCD Resolution 0.01 L/min (instant) / 1 L (accumulated)

- Mechanical connection MF5706=BSPP 1/4 BSPP MF5708=3/8” MF5712=BSPP 1/2”

or MF5706=NPT 1/4” or MF5708=NPT3/8” or MF5712=NPT/ 1/2”

- Storage temperature -20 ~ 70 °C

- Calibration Reference conditions 20°C, 101.325 kPa, air

- Ingress Protection IP50

- Gas compatibility non-corrosive

- CE EN61326-1; -2; -3

Installation

Installation Procedures for a Micro Mass Flow Meter

Installing a micro mass flow meter requires careful attention to detail to ensure accurate measurement and reliable performance. Follow these procedures to install your micro mass flow meter correctly:

Preparation

Review Documentation: Before starting, read the manufacturer’s installation manual and specifications. This will provide specific guidelines related to the model you are installing, including any unique requirements or recommendations.

Gather Tools and Equipment: Ensure you have all necessary tools and materials, such as wrenches, pipe cutters, sealants, mounting brackets, fittings, and any required adapters. Check that you have the correct components for integrating the meter into your system.

Select the Installation Location: Choose an appropriate location for the flow meter. It should be installed in a straight section of the pipe, ideally with at least 10-15 pipe diameters upstream and 5-10 pipe diameters downstream of straight pipe sections to ensure accurate flow measurement. The location should also allow for easy access for future maintenance and calibration.

Ensure System Conditions: Verify that the pipeline is depressurized, and that the system is turned off before beginning the installation. This prevents any leaks or spills and ensures safety.

Preparing the Installation Site

Clean the Pipe: Clean the section of the pipeline where the flow meter will be installed. Remove any debris, rust, or old sealant to ensure a clean connection and prevent contamination.

Check Pipe Alignment: Ensure the pipe is properly aligned and free of any misalignments or vibrations. Proper alignment helps to avoid measurement errors and potential damage to the meter.

Installing the Micro Mass Flow Meter

Verify Orientation and Alignment: Confirm that the flow meter is oriented according to the manufacturer’s specifications. Most micro mass flow meters should be installed in a vertical position or as indicated by the manufacturer. Check the direction of flow indicated by an arrow on the device to ensure proper installation.

Install the Flow Meter:

- Threaded Connections: Apply a suitable thread sealant to the threads of the flow meter and pipe fittings to prevent leaks. Hand-tighten the meter into place, and then use a wrench to secure it. Avoid over-tightening to prevent damage to the flow meter or pipe.

- Flanged Connections: If the flow meter uses flanged connections, align it with the pipe flanges and place any necessary gaskets between the flanges. Secure the meter with bolts, tightening them evenly in a cross pattern to ensure a uniform seal.

Secure Mounting: For flow meters with mounting brackets, ensure the meter is securely attached to the mounting platform. Follow the manufacturer’s instructions for mounting and use the provided hardware to secure the meter in place.

Electrical and Signal Connections

Connect Power Supply: If the flow meter requires an external power source, connect it according to the manufacturer’s specifications. Ensure that the voltage and current ratings match the requirements of the meter.

Connect Signal Wires: Connect the output signal wires from the flow meter to the appropriate data acquisition or control system. Follow the wiring diagram provided by the manufacturer to ensure correct connections.

Verify Electrical Connections: Check all electrical connections for secure and correct placement. Ensure that there are no loose or exposed wires, and that all connections are properly insulated.

System Integration and Testing

Repressurize the System: Gradually reintroduce pressure to the pipeline and check for any leaks around the flow meter and connections. Monitor the system for any signs of leaks or pressure issues.

Conduct a Test Run: Perform a test run to verify that the flow meter is operating correctly. Check the readings on the display unit and compare them with expected values. Ensure that the flow meter is providing stable and accurate measurements.

Calibrate the Meter: Follow the manufacturer’s guidelines for calibrating the flow meter. Use standard calibration fluids if required and adjust the settings as necessary to ensure accurate measurements. Calibration helps to align the meter’s readings with known standards.

Final Checks and Documentation

Inspect the Installation: Perform a final inspection of the installation to ensure that the flow meter is properly installed and functioning as expected. Verify that all connections are tight, and that there are no visible issues or misalignments.

Document the Installation: Record all relevant details about the installation, including the location, connection types, calibration settings, and any observations from the testing phase. This documentation is valuable for future reference and maintenance.

Provide Training: If applicable, train relevant personnel on how to operate and maintain the flow meter. Ensure they understand how to interpret the readings, perform basic troubleshooting, and carry out routine maintenance tasks.

Ongoing Maintenance and Monitoring

Schedule Regular Inspections: Plan for regular inspections to check the condition and performance of the flow meter. Inspect for signs of wear, damage, or contamination, and ensure that all connections remain secure.

Monitor Performance: Continuously monitor the performance of the flow meter to ensure accurate measurements. Address any issues promptly to maintain optimal operation.

By following these installation procedures, you can ensure that your micro mass flow meter is set up correctly, providing accurate and reliable measurements for your application. Proper installation and ongoing maintenance are essential to achieving the best performance and longevity from your flow meter.

Maintenance

Routine Inspection: Regularly inspect the flow meter for signs of wear, damage, or contamination. Check for any physical damage to the sensor or housing and ensure that all connections are secure.

Cleaning: Depending on the fluid being measured, periodic cleaning may be required to prevent buildup or contamination. Use appropriate cleaning agents and follow manufacturer guidelines to avoid damaging the meter.

Calibration: Perform regular calibration according to the manufacturer’s recommendations. Use standard calibration fluids or procedures and adjust the meter as needed based on calibration results.

Component Checks: Inspect and test individual components such as sensors, transmitters, and display units to ensure they are functioning correctly. Replace any faulty components promptly.

Documentation: Maintain detailed records of maintenance activities, including inspections, cleaning, calibrations, and repairs. This documentation is essential for tracking the meter’s performance and planning future maintenance.

Q&A

A Q&A Micro Mass Flow Meter, which stands for “question and answer for Micro Mass Flow Meter,” is a format commonly used to facilitate communication and exchange of information. In a Q&A, one person asks a question, and another person or group provides an answer or response to that question. This format is widely used in various contexts, such as interviews, discussions, presentations, or online forums. It allows for a structured and organized way of addressing inquiries and obtaining relevant information. Is there anything specific you would like to know about the Q&A Micro Mass Flow Meter?

Q: What is a micro mass flow meter?

A: A micro mass flow meter is a type of flow meter designed to accurately measure very low flow rates, typically in the range of microliters per minute to a few milliliters per minute. They are often used in applications where precise control of fluid flow is critical. This includes microfluidics, lab-on-a-chip devices, and medical instrumentation.

Q: How do micro mass flow meters work?

A: Micro mass flow meters work by measuring the flow of fluid through a small channel or tube using various sensing techniques, such as thermal, Coriolis, or pressure-based methods. They typically incorporate microfabrication techniques to create microfluidic channels and structures on a small chip or device, allowing for highly accurate and sensitive flow measurements.

Q: What are some applications for micro mass flow meters?

A: Micro mass flow meters are commonly used in a variety of industries, including medical and pharmaceutical research. They are also commonly used in chemical processing and environmental monitoring. They are often used to measure the flow of very small volumes of fluids in laboratory experiments. In addition, it may also be used in the manufacturing of microscale devices.

Q: What are the advantages of using micro mass flow meters?

A: Micro mass flow meters offer several advantages over traditional flow meters, including high accuracy. Another advantage would be sensitivity, and rangeability, as well as low power consumption and small size. They are well-suited for use in microfluidic devices and other applications where space is limited, and precise control of fluid flow is critical.

Q: What factors should be considered when selecting a micro mass flow meter?

A: When selecting a micro mass flow meter, several factors should be considered. Considerations that include the specific application, the type of fluid being measured, the flow rate and range, and the required accuracy and resolution. Other factors to consider include the operating temperature and pressure range. In addition, it will consider the type of output signal required and the installation and maintenance requirements.

Q: Can micro mass flow meters measure the flow of gases and liquids?

A: Yes, micro mass flow meters can measure the flow of both gases and liquids. They are commonly used to measure low flow rates of gases such as oxygen, nitrogen, and carbon dioxide, as well as liquids such as water, oil, and chemical solutions.

Q: How accurate are micro mass flow meters?

A: Micro mass flow meters are highly accurate and can typically achieve measurement accuracies of 1-2% or better. However, this depends on the specific type and design. Some micro mass flow meters can achieve even higher accuracies. This particularly occurs when used in conjunction with calibration techniques and advanced signal-processing algorithms.

Q: How are micro mass flow meters calibrated?

A: Micro mass flow meters are typically calibrated using precision reference standards and techniques, such as gravimetric, volumetric, or tracer gas methods. The calibration process involves comparing the output of the flow meter to the known flow rate of the reference standard. Once that is known, it adjusts the meter’s signal processing algorithms as necessary to achieve accurate and reliable flow measurements.

Q: What are some limitations of using micro mass flow meters?

A: One limitation of micro mass flow meters is that they may not be suitable for measuring high flow rates. In addition, they may not be suitable for flows of viscous or dense fluids. They may also be more sensitive to changes in temperature, pressure, and other environmental factors compared to larger flow meters. Additionally, the small size and complexity of micro-mass flow meters may make them more expensive. This makes it challenging to manufacture and maintain.

Buy

Coriolis Flow Meters

Advantages / Disadvantages

Micromass flow meters are instruments used for measuring the flow rate of gases or liquids in small-scale applications. Here are some advantages and disadvantages of micro mass flow meters:

Advantages

High Accuracy: Micro mass flow meters are known for their precise measurement capabilities, making them ideal for applications where accuracy is crucial.

Compact Size: These meters are designed to be small and portable, making them suitable for use in space-constrained environments.

Wide Range of Applications: Micro mass flow meters can be used in various industries such as medical devices, biotechnology, automotive, and more.

Low Flow Measurement: They are capable of measuring very low flow rates accurately, which is beneficial for many applications that deal with small quantities of fluids.

Furthermore, micro mass flow meters offer several advantages over traditional flow measurement techniques. Their small size and low power consumption enable integration into portable devices and systems, making them suitable for on-site measurements and remote monitoring applications. They also provide real-time flow data, allowing for instant feedback and control of critical processes.

The use of micro-mass flow meters can lead to increased efficiency and cost savings in various industries. For instance, in pharmaceutical research, precise flow control is critical for ensuring accurate dosing of medications and reducing waste. In fuel cell testing, accurate flow measurements are necessary to optimize fuel cell performance and improve energy efficiency.

In conclusion, a micro mass flow meter is a highly advanced instrument used for precise and accurate measurement of flow rates in small fluid volumes. With their compact size, high sensitivity, and real-time flow data, these meters offer significant advantages over traditional flow measurement techniques. They play a crucial role in various industries, contributing to improved efficiency and cost savings.

Disadvantages

Cost: Micro mass flow meters can be more expensive compared to traditional flow meters due to their advanced technology and precision.

Sensitivity to Contaminants: Some micro mass flow meters can be sensitive to impurities or contaminants in the fluid being measured, which may affect their accuracy over time.

Calibration: These instruments may require frequent calibration to maintain their accuracy, which can be time-consuming and costly.

Pressure Drop: Using a micro mass flow meter can sometimes result in a pressure drop in the system being measured, affecting overall system performance.

It’s essential to consider these factors when selecting a micro mass flow meter for your specific application to ensure optimal performance and reliability.

Applications

Micro Mass Flow Meters Applications suitable for:

- Precision Measurement & Control

- Gas Mixing & Blending

- Ultra Low Flow Control

- Artificial Atmospheres

- Research

Micro Mass Flow Meters are precision instruments used for measuring low flow rates of gases or liquids in various applications requiring accuracy and reliability. Here are some common applications for a Micro Mass Flow Meter:

Medical Devices: Micro Mass Flow Meters are utilized in medical equipment such as respiratory devices, anesthesia machines, ventilators, and gas analyzers to monitor and control the flow of gases for patient treatment, diagnostics, and medical research.

Analytical Instruments: In laboratories, research facilities, and pharmaceutical companies, Micro Mass Flow Meters are integrated into gas chromatographs, mass spectrometers, spectrophotometers, and other analytical instruments for precise gas flow control, sample analysis, and process optimization.

Fuel Cell Testing: Micro Mass Flow Meters play a critical role in fuel cell testing and hydrogen research applications to measure gas flow rates, composition, and hydrogen purity levels for fuel cell efficiency studies, stack performance evaluation, and alternative energy development.

Semiconductor Manufacturing: Micro Mass Flow Meters are essential in semiconductor fabrication processes, cleanrooms, and wafer manufacturing facilities to deliver accurate gas flow control for chemical vapor deposition (CVD), etching, ion implantation, and other semiconductor production steps.

Environmental Monitoring: Micro Mass Flow Meters are employed in environmental monitoring systems, air quality sensors, greenhouse gas analyzers, and emissions testing equipment to measure gas flows, pollutant concentrations, and ambient air quality parameters for environmental assessments and pollution control.

Aerospace and Defense: Micro-Mass Flow Meters are used in aerospace and defense industries for aircraft fuel systems, rocket propulsion testing, spacecraft life support systems, and military applications requiring precise gas flow measurement, control, and monitoring.

Biotechnology and Life Sciences: In bioreactors, fermentation processes, cell culture systems, and biopharmaceutical manufacturing, Micro Mass Flow Meters help regulate gas flows, nutrient delivery, and oxygen levels critical for cell growth, protein production, and bioprocess optimization.

Energy Research: Micro Mass Flow Meters are employed in energy research labs, renewable energy projects, gas turbine testing facilities, and nuclear reactors to measure fuel gas flows, combustion rates, and thermal efficiency for energy generation studies and performance analysis.

Microfluidics and Lab-on-a-Chip Devices: Micro Mass Flow Meters are integrated into microfluidic systems, lab-on-a-chip devices, and microscale analytical platforms for biological assays, chemical synthesis, drug discovery, and microfabrication applications requiring precise fluid handling and flow control at small volumes.

These applications demonstrate the versatility and importance of Micro Mass Flow Meters in a wide range of industries and research fields where accurate flow measurement, low flow rate control, and precise fluid handling are essential for achieving desired outcomes and advancing technological innovation.

Downloads

Drawings

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.