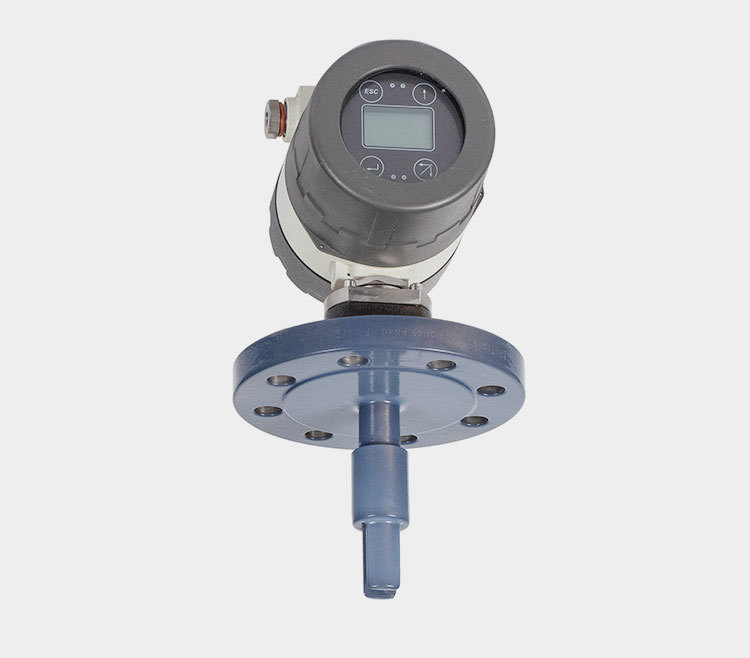

Specifications

Measure the density, concentration, gravity, and temperature of the liquid

- The accuracy will not be affected by temperature, pressure, density, viscosity, etc.

- Accuracy: ±0.002g/cc; ±0.001g/cc optional

- Applications: pipeline interface detection, mineral slurry solids monitoring, and corrosive acid concentration control; Where fast-response density and concentration monitoring is required.

- Moreover, it Increased installation flexibility with continuous, real-time measurement in pipelines, by-pass loops, and tanks

- Also, Choose from a wide range of corrosion-resistant materials for measuring the density and concentration of critical chemicals Support protocols for connection to DCS, PLC, and flow computers

- Finally, Expand usage with a hazardous area-approved, head-mounted transmitter that supports local configuration and display

Q&A

A Q&A Density Flow Meters, which stands for “question and answer for Density Flow Meters,” is a format commonly used to facilitate communication and exchange of information. Also, in a Q&A, one person asks a question, and another person or group provides an answer or response to that question. In addition, this format is widely used in various contexts, such as interviews, discussions, presentations, or online forums. Furthermore, it allows for a structured and organized way of addressing inquiries and obtaining relevant information. Finally, is there anything specific you would like to know about Q&A Density Flow Meters?

Q: What is a density flow meter?

A: A Q&A Density Flow Meters are a type of flow meter that measures the density of a fluid With this we use that information to calculate the flow rate of the fluid.

Q: How does a density flow meter work?

A: A density flow meter works by measuring the frequency shift of a sound wave that is sent through the fluid. In addition, the frequency shift is proportional to the density of the fluid, which can then be used to calculate the flow rate of the fluid.

Q: What are the advantages of using a density flow meter?

A: Some advantages of using a density flow meter include:

-

- High accuracy and precision in measuring flow rate

-

- Additionally, it can be used for a wide range of fluids, including liquids, gases, and slurries

-

- Can measure both low and high flow rates

-

- Furthermore, it can be used in harsh environments, including high-pressure and high-temperature applications

-

- Also, this can be used to measure the density of the fluid in addition to the flow rate, providing valuable information about the fluid being measured

Q: What are some common applications for density flow meters?

A: Density flow meters are commonly used in a variety of industries, including oil and gas, chemical processing, and food and beverage. Also, they are often used in applications where accurate measurement of flow rate and density is critical. Also, as in custody transfer applications, process control, and quality control.

Q: What are some potential limitations or drawbacks of using a density flow meter?

A: Some potential limitations of using a density flow meter include:

-

- Higher cost compared to other types of flow meters

-

- Can be affected by changes in fluid temperature and pressure, which can affect the accuracy of the meter

-

- Furthermore, it can be sensitive to changes in fluid properties, such as changes in viscosity or density

-

- Also, it can be affected by bubbles or entrained air in the fluid, which can affect the accuracy of the meter

Q: How can a density flow meter be calibrated?

A: A density flow meter can be calibrated using a reference standard, such as a calibrated container or a more accurate flow meter. In addition, the fluid is passed through the density flow meter and the reference standard at the same time. Moreover, the readings from both devices are compared to determine any differences in accuracy. Finally, the meter can then be adjusted accordingly to improve its accuracy.

Q: What materials are density flow meters typically made from?

A: Density flow meters can be made from a variety of materials depending on the application. This includes metals such as stainless steel, titanium, and aluminum, as well as plastics such as PVC and PTFE. Finally, the choice of material depends on factors such as the type of fluid being measured. Other factors are the temperature and pressure of the fluid and the required level of accuracy.

Q: Can density flow meters be used in hazardous or corrosive environments?

A: Density flow meters can be designed and constructed to be used in hazardous or corrosive environments. Moreover, when using materials such as stainless steel or special coatings to resist corrosion. It is also by using explosion-proof housings and other safety features to prevent the risk of fires or explosions.

Q: What is the typical accuracy of a density flow meter?

A: The typical accuracy of a Q&A Density Flow Meter depends on factors such as the flow range. Also, accuracy is impacted by the quality of the sensor, and the calibration method used. Finally, in general, the accuracy of a density flow meter can range from 0.1% to 2% of the actual flow rate.

Q: How does the installation of a density flow meter affect the flow of the fluid being measured?

A: The installation of a density flow meter can affect the flow of the fluid being measured. This is especially true if the meter obstructs the flow path. Also, to minimize the impact of the meter on the flow, it is important to ensure that the meter is installed in a section of the pipe. Furthermore, this is where the flow is fully developed and has a stable velocity profile. Additionally, it is also important to choose a Density flow meter with a low-pressure drop to minimize any impact on the flow rate.

Q: Can density flow meters be used to measure the flow of multiphase fluids?

A: Density flow meters can be used to measure the flow of multiphase fluids, which are fluids that contain a mixture of two or more phases. Also, the phases such as oil and water or gas and liquid. Also, however, the accuracy of the meter may be affected by the presence of multiple phases. Finally, considering this, additional measurements may be needed to accurately determine the flow rate.

Q: What is the maintenance required for density flow meters?

A: The maintenance required for Q&A Density Flow Meters depends on factors such as the type of meter. It also depends upon the application and the environment in which the meter is used. Additionally, in general, regular calibration and cleaning of the meter is recommended to ensure accurate readings. Finally, the meter should also be inspected regularly for any signs of damage or wear. Now, any necessary repairs or replacements should be made promptly to prevent further damage.

Q: Can a density flow meter be used in both liquids and gases?

A: Yes, a density flow meter can be used to measure the flow of both liquids and gases. In addition, this occurs as long as the meter is designed and calibrated for the specific fluid being measured.

Q: What is the cost of a density flow meter?

A: The cost of a Q&A Density Flow Meter can vary widely depending on factors such as the type of meter. Also, you need to consider the size, the materials used, and the level of accuracy required. Also, in general, density flow meters are more expensive than other types of flow meters. Additionally, the prices range from a few hundred dollars for a basic meter to tens of thousands of dollars. These costs are for a high-precision meter.

Buy

Density Flow Meters

Advantages / Disadvantages

Advantages of a Density Flow Meter

The Density Meter offers several advantages over other flow measurement technologies. Some of the notable advantages include:

Real-Time Data: The Meter provides continuous, real-time density and flow rate measurements, enabling prompt response to process variations and ensuring product quality.

Minimal Pressure Drop: Unlike some other flow measurement devices, the Meter has a negligible impact on the fluid flow, resulting in minimal pressure drop.

Wide Dynamic Range: It can handle fluids with a wide range of densities and velocities, making it adaptable to different process conditions.

Accurate Measurements: Density flow meters provide precise measurements of fluid density and flow rates, ensuring reliable data for process control and optimization.

Real-time Monitoring: These meters offer continuous monitoring of density and flow, enabling quick detection of any variations or abnormalities in the fluid being measured.

Versatility: Density flow meters can be used with a wide range of fluids, making them suitable for diverse industrial applications across different sectors.

Improved Process Efficiency: By providing accurate density and flow data, these meters help improve process efficiency, reduce waste, and enhance product quality.

Low Maintenance: Density flow meters are often low-maintenance devices, requiring minimal calibration and upkeep to ensure consistent performance.

Disadvantages of a Density Flow Meter

Cost: Density flow meters can be expensive to purchase and install, making them less budget-friendly compared to some other flow measurement devices.

Sensitivity to Installation Conditions: Proper installation and calibration are crucial for accurate measurements with density flow meters. Factors like pipe size, flow conditions, and fluid properties can impact their performance.

Complex Setup: Some density flow meters may require complex setup procedures or additional equipment for optimal functionality, which can pose a challenge for inexperienced users.

Risk of Contamination: External factors such as impurities or contaminants in the fluid being measured can affect the accuracy and reliability of density flow meters.

Limited Application in Some Fluids: Certain types of fluids or conditions may not be suitable for density flow meter measurements, limiting their applicability in specific environments or industries.

Applications

Applications with Density Flow Meter

The Density Meter finds its application in various industries where precise density and flow measurements are vital. Some of the notable applications include:

Oil and Gas: It is extensively used in upstream, midstream, and downstream processes for measuring the density and flow of crude oil, refined products, and natural gas.

Chemical Processing with Density Flow Meter: The Density Meter enables accurate monitoring of chemical processes, helping maintain quality control and optimize production.

Food and Beverage: It plays a crucial role in the food and beverage industry by ensuring accurate dosing, blending, and custody transfer of liquids like syrups, juices, and alcoholic beverages.

Pharmaceutical and Biotech: This flow meter is employed in pharmaceutical manufacturing to ensure precise measurements during the processing of liquids and various raw materials.

Pipeline interface Inspection, Slurry Solids monitoring, and corrosive acid concentration control; density and concentration monitoring that require rapid response. Furthermore, continuously measure pipelines in real-time with your Meter through pipelines and storage tanks to increase installation flexibility and choose from a variety of corrosion-resistant materials to measure the density and concentration of key chemicals.

Also, it supports protocols connected to DCS, PLC, and Flow computers. Also, Pass hazardous area area-approved head-mounted Transmitters extend the range of use, and the transmitter supports local configuration and display.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.