Description

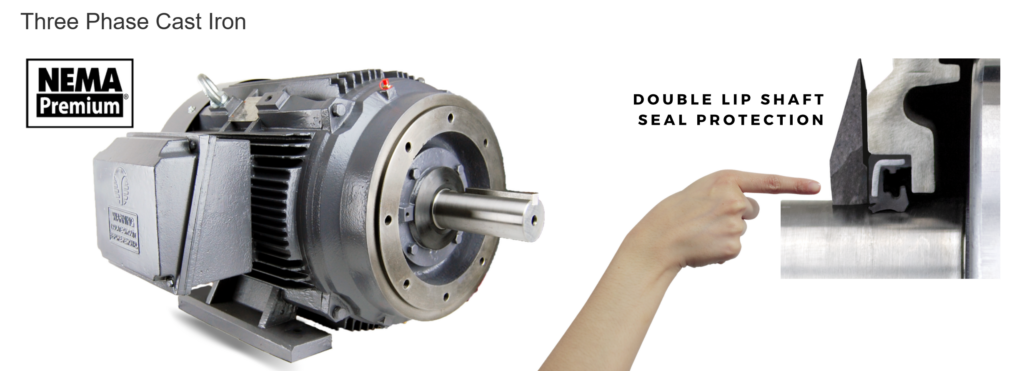

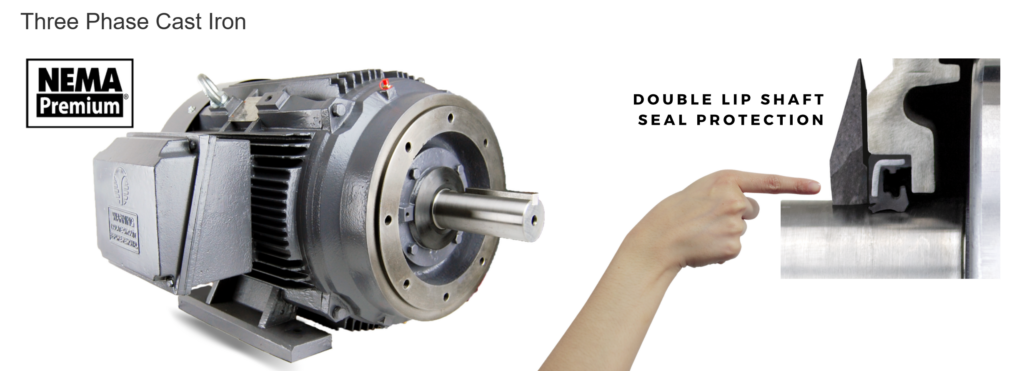

NEMA Premium TEFC Motors – Green Line are renowned for their high-efficiency levels, ensuring optimal energy usage and cost savings for various industrial and commercial applications. These motors are designed to meet or exceed the stringent efficiency levels set by the National Electrical Manufacturers Association (NEMA), a standard-setting organization for electrical equipment in the United States.

At the core of NEMA Premium TEFC Motors – Green Line is its efficient design and construction, which enables it to convert electrical energy into mechanical power with minimal losses. These motors are typically equipped with high-quality materials, precision engineering, and advanced technologies that help reduce energy consumption and operating costs while maintaining reliable performance.

Efficiency Levels

One key feature of NEMA Premium TEFC Motors – Green Line is their improved efficiency ratings compared to standard motors. These motors are designed to operate at efficiency levels that exceed the minimum requirements set by NEMA, resulting in lower energy consumption and reduced carbon footprint. By utilizing premium-grade materials, such as high-grade copper windings and high-quality steel laminations, can minimize energy losses and heat generation during operation.

In addition to their superior efficiency, are also known for their durability and longevity. These motors are built to withstand harsh operating conditions, frequent starts and stops, and varying loads without compromising performance. With proper maintenance and care, NEMA Premium TEFC Motors – Green Line can provide years of reliable service, reducing downtime and maintenance costs for end-users.

Various Configurations NEMA Premium TEFC Motors – Green Line

Another important aspect of NEMA Premium TEFC Motors – Green Line is its versatility and compatibility with various applications. These motors are available in various sizes, configurations, and power ratings, making them suitable for diverse industrial and commercial settings. Whether used in pumps, compressors, fans, conveyors, or other machinery, NEMA Premium Efficiency Motors offers consistent performance and energy savings across different applications.

Variable Controlled Speed Control

Furthermore, NEMA Premium Efficiency Motors often offers advanced features and options to enhance their performance and functionality. These may include premium bearings for smooth operation, rugged enclosures for protection against environmental factors, and advanced cooling systems to maintain optimal operating temperatures. Additionally, some NEMA Premium Efficiency Motors may be compatible with variable frequency drives (VFDs) for improved speed control and energy efficiency.

Overall, NEMA Premium Efficiency Motors represents a top-of-the-line choice for industries and businesses seeking to reduce energy consumption, cut operating costs, and minimize their environmental impact. With their superior efficiency, durability, and performance, these motors offer a compelling solution for a wide range of applications, making them a preferred choice for those prioritizing energy efficiency and sustainability in their operations.

Optimal Energy Usage

NEMA Premium Efficiency Motors are renowned for their high-efficiency levels. In addition, this ensuring optimal energy usage and cost savings for various industrial and commercial applications. These motors are designed to meet or exceed the stringent efficiency levels set by the National Electrical Manufacturers Association (NEMA). Also, a standard-setting organization for electrical equipment in the United States.

At the core of a NEMA Premium Efficiency Motor is its efficient design and construction. Which enables it to convert electrical energy into mechanical power with minimal losses. These motors are typically equipped with high-quality materials, precision engineering, and advanced technologies that help reduce energy. It reduces energy consumption and operating costs while maintaining reliable performance.

Efficiency Ratings NEMA Premium TEFC Motors – Green Line

One key feature of NEMA Premium Efficiency Motors is their improved efficiency ratings compared to standard motors. These motors are designed to operate at efficiency levels that exceed the minimum requirements set by NEMA. As a result, this lowers energy consumption and reduced carbon footprint. By utilizing premium-grade materials, such as high-grade copper windings and high-quality steel laminations. Finally, NEMA Premium Efficiency Motors can minimize energy losses and heat generation during operation.

In addition to their superior efficiency, NEMA Premium Efficiency Motors are also known for their durability and longevity. These motors are built to withstand harsh operating conditions, frequent starts and stops, and varying loads without compromising performance. With proper maintenance and care, NEMA Premium Efficiency Motors can provide years of reliable service. Furthermore, reducing downtime and maintenance costs for end-users.

Another important aspect of NEMA Premium Efficiency Motors is its versatility and compatibility with various applications. These motors are available in various sizes, configurations, and power ratings, making them suitable for diverse industrial and commercial settings. Whether used in pumps, compressors, fans, conveyors, or other machinery, NEMA Premium Efficiency Motors offers consistent performance. It also offers and energy savings across different applications.

Advanced Features

Furthermore, NEMA Premium Efficiency Motors often offers advanced features and options to enhance their performance and functionality. These may include premium bearings for smooth operation and rugged enclosures for protection. Furthermore, protection against environmental factors, and advanced cooling systems to maintain optimal operating temperatures. Additionally, some NEMA Premium Efficiency Motors may be compatible with variable frequency drives (VFDs). Moreover, assisting for improved speed control and energy efficiency.

Overall, NEMA Premium Efficiency Motors represents a top-of-the-line choice for industries and businesses. Businesses seeking to reduce energy consumption, cut operating costs, and minimize their environmental impact. With their superior efficiency, durability, and performance, these motors offer a compelling solution. A solution for a wide range of applications, making them a preferred choice. A choice for those prioritizing energy efficiency and sustainability in their operations.

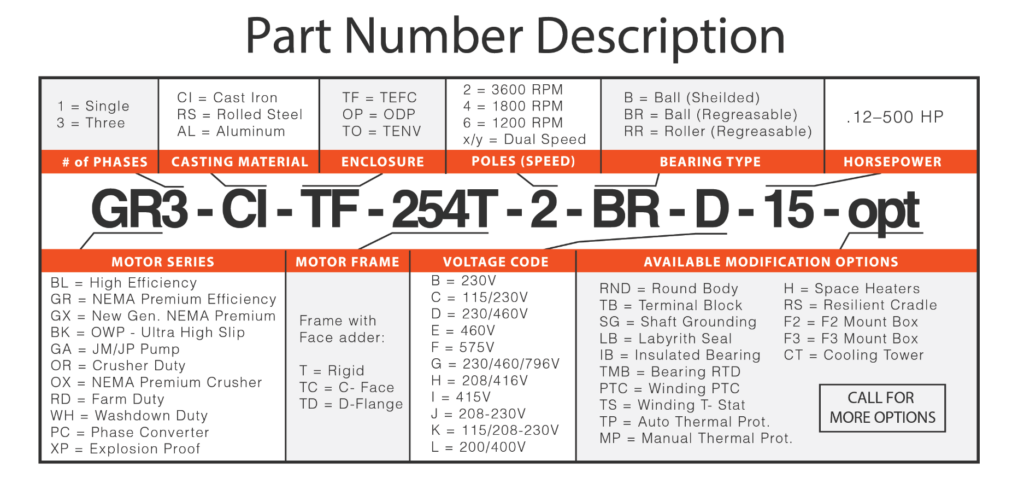

Specifications

| Standard Features |

|

- NEMA Premium Efficiency

- 50Hz Capable at 1.0SF

- Enclosed Fan Cooled (TEFC)

- Continuous (S1) Duty

- 40°C Ambient Rating

- IP55 Protection

- Inverter Rated 15:1 Constant Torque (1.0 SF on VFD) MG1 Pt. 31

- Class F Insulation

- Class B temperature Rise

- Vacuum Pressure Impregnated Stator

- IEEE 45 Marine Duty

- Graphite Gray

- 1.25 Service Factor with 60Hz TEFC operation

- Class 1, Division 2, Groups A, B, C & D Compliant

- 36 Month Warranty from date of purchase

|

- Shaft Grounding Brush Installed

- Fully Epoxy Potted Conduit Box Entry

- Stainless Steel Anti-Corrosion Fan Cover

- Brake Kit & Encoder Kit Ready

- PTC Thermal Protection Installed

- Removable Feet F1, F2, F0 convertible

- The Conduit Box is 90° Rotatable

- Full Die-Cast Aluminum Frame

- Anti-microbial (Tropicalization) coating on Stator

- Powder Coated RAL 7024

- Over-Sized Shielded Bearings

- Viton Double Lip Shaft Seals

- TENV Capable at 1.0 SF

- 1045 steel shaft

- Stainless steel nameplate

- Corrosion Resistant Blue Zinc Hardware

|

Installation

Installing a NEMA Premium Efficiency Motor correctly is crucial to ensure its optimal performance, longevity, and safety. Here are general installation instructions to guide you through the process:

Safety First: Before starting the installation process, make sure to wear appropriate personal protective equipment (PPE) such as gloves and goggles. Ensure that the power source is turned off and locked out to prevent accidental start-up.

Location: Choose a well-ventilated and clean location for the motor installation, away from any sources of heat, moisture, or vibration that could affect its performance.

Mounting: Securely mount the motor on a flat, stable surface using the appropriate mounting hardware. Ensure that the motor is aligned properly with the driven equipment to prevent misalignment issues.

Electrical Connections:

a. Check the motor nameplate for the correct voltage and current ratings.

b. Make sure the power supply matches the motor requirements.

c. Connect the motor leads to the power supply following the manufacturer’s recommended wiring diagram.

d. Ensure all electrical connections are tight, secure, and properly insulated to prevent short circuits or electrical hazards.

Grounding: Properly ground the motor according to local electrical codes and regulations to prevent electrical shock hazards and ensure safety.

Cooling: Ensure adequate ventilation around the motor to facilitate cooling and prevent overheating. Do not obstruct ventilation openings on the motor housing.

Belt and Pulley Alignment (if applicable):

a. If the motor is belt-driven, ensure proper alignment between the motor pulley and the driven pulley.

b. Adjust belt tension according to manufacturer recommendations to prevent slippage or excessive wear.

Startup and Testing:

a. Before starting the motor, double-check all connections and ensure that the installation is complete

b. Slowly energize the motor and observe its operation for any unusual noise, vibrations, or heat buildup.

c. Use a tachometer to verify the motor’s speed and compare it to the rated speed on the nameplate.

Maintenance: Establish a regular maintenance schedule for the motor, including lubrication, cleaning, and inspection of components to ensure optimal performance and longevity.

Documentation: Keep a record of the motor’s installation date, maintenance activities, and any issues encountered for future reference.

Always refer to the manufacturer’s specific installation instructions and guidelines provided with the NEMA Premium Efficiency Motor to ensure proper installation and adherence to all safety regulations and standards. If in doubt, consult a qualified electrician or technician for assistance.

Maintenance

Proper maintenance is essential to ensure the long-term performance, efficiency, and reliability of a NEMA Premium Efficiency Motor. Here are general maintenance instructions to help you keep your motor in optimal condition:

Regular Inspection:

Perform routine visual inspections of the motor for signs of wear, damage, or overheating.

Check for any unusual noise, vibrations, or odors during operation, which could indicate potential issues.

Lubrication:

Monitor the motor’s lubrication levels and follow the manufacturer’s recommendations for lubrication intervals and types.

Ensure proper lubrication of bearings and moving parts to prevent friction and wear.

Cleaning:

Keep the motor clean by regularly removing dirt, dust, and debris from the exterior and ventilation openings.

Use a soft brush or compressed air to clean the motor without causing damage to the components.

Temperature Monitoring:

Monitor the motor’s operating temperature regularly using a temperature gun or other suitable tools.

Ensure that the motor does not exceed the recommended temperature limits during operation.

Vibration Analysis:

Periodically conduct vibration analysis tests to detect any irregularities or imbalances in the motor.

Address any vibration issues promptly to prevent damage to the motor and connected equipment.

Electrical Testing:

Conduct regular electrical tests, such as insulation resistance tests, to ensure electrical integrity and prevent potential short circuits or electrical faults.

Check motor windings for signs of insulation breakdown or degradation.

Alignment Check:

Verify the alignment of the motor with the driven equipment, such as pumps or fans, to prevent issues like belt misalignment or coupling problems.

Bearing Maintenance:

Inspect bearings for wear, lubrication levels, and abnormal noise during operation.

Replace bearings as needed and follow proper installation procedures.

Balancing and Alignment:

Periodically check and adjust the balance and alignment of the motor shaft to prevent excessive vibration and premature wear on bearings and other components.

Professional Service:

If any significant issues are detected or if maintenance tasks require specialized knowledge or tools, consider consulting a qualified electrician or technician for assistance.

By following these maintenance instructions and establishing a regular maintenance schedule for your NEMA Premium Efficiency Motor, you can help ensure its continued reliability, efficiency, and longevity. Be sure to refer to the manufacturer’s specific maintenance guidelines and recommendations for your motor model to maintain peak performance and prevent unexpected downtime.

Applications

NEMA Premium Efficiency Motors are widely used in a variety of industrial, commercial, and residential applications due to their energy-saving capabilities, superior performance, and reliability. Here are some common applications that involve NEMA Premium Efficiency Motors:

HVAC Systems:

NEMA Premium Efficiency Motors are frequently used in heating, ventilation, and air conditioning (HVAC) systems to power fans, blowers, pumps, and compressors. These motors help reduce energy consumption and operating costs in commercial and residential buildings.

Pumps and Compressors:

NEMA Premium Efficiency Motors are ideal for driving pumps and compressors in water treatment plants, wastewater facilities, irrigation systems, and industrial processes. Their high efficiency and reliability make them well-suited for continuous-duty applications.

Material Handling Equipment:

Conveyor belts, mixers, crushers, and other material handling equipment often utilize NEMA Premium Efficiency Motors for efficient and reliable operation in manufacturing, distribution centers, and warehouses.

Industrial Fans:

NEMA Premium Efficiency Motors power industrial fans are used for ventilation, cooling, and process air handling in manufacturing facilities, commercial buildings, data centers, and other industrial settings.

Machine Tools:

CNC machines, lathes, milling machines, grinders, and other machine tools benefit from the energy efficiency and precise control offered by NEMA Premium Efficiency Motors, ensuring accurate and consistent performance.

Water and Wastewater Treatment:

NEMA Premium Efficiency Motors are commonly found in water and wastewater treatment plants to power pumps, mixers, aerators, and other equipment, helping to optimize energy usage and ensure reliable operation.

Agricultural Equipment:

Farm equipment such as irrigation pumps, grain augers, feed mixers, and ventilation systems rely on NEMA Premium Efficiency Motors for efficient and durable performance in agricultural operations.

Oil and Gas Industry:

NEMA Premium Efficiency Motors are used in pumps, compressors, and other equipment in the oil and gas industry to enhance energy efficiency, minimize downtime, and ensure reliable operation in demanding environments.

Mining and Quarrying:

Mining equipment, crushers, conveyors, and hoists in mining and quarrying operations can benefit from the energy savings and robust performance provided by NEMA Premium Efficiency Motors.

Recycling Equipment:

Shredders, compactors, balers, and sorting equipment in recycling facilities utilize NEMA Premium Efficiency Motors for efficient and sustainable operation, helping to reduce energy costs and environmental impact.

These are just a few examples of the diverse applications that benefit from the energy efficiency, reliability, and performance of NEMA Premium Efficiency Motors. Their versatility and effectiveness make them a popular choice across various industries and sectors where optimizing energy usage and reducing operating costs are key priorities.

Q&A

Q: What is a NEMA Premium Efficiency Motor?

A: A NEMA Premium Efficiency Motor is a type of electric motor that meets or exceeds the efficiency levels specified by the National Electrical Manufacturers Association (NEMA). These motors are designed to convert electrical energy into mechanical power with minimal losses, resulting in energy savings and reduced operating costs.

Q: What are the key benefits of using NEMA Premium Efficiency Motors?

A: The key benefits of using NEMA Premium Efficiency Motors include energy savings, lower operating costs, improved performance, enhanced reliability, environmental sustainability, regulatory compliance, and potential incentives or rebates for using energy-efficient equipment.

Q: How do NEMA Premium Efficiency Motors differ from standard efficiency motors?

A: NEMA Premium Efficiency Motors are designed with higher efficiency levels compared to standard motors, resulting in lower energy consumption and reduced heat generation. These motors use high-quality materials, advanced engineering techniques, and precision manufacturing to optimize performance and energy efficiency.

Q: In which applications are NEMA Premium Efficiency Motors commonly used?

A: NEMA Premium Efficiency Motors are commonly used in a wide range of applications, including HVAC systems, pumps and compressors, material handling equipment, industrial fans, machine tools, water and wastewater treatment, agricultural equipment, oil and gas industry, mining and quarrying, and recycling equipment, among others.

Q: How can I identify a NEMA Premium Efficiency Motor?

A: NEMA Premium Efficiency Motors are typically labeled or marked with a NEMA Premium Efficiency logo or certification, indicating that the motor meets the high-efficiency standards set by NEMA. Additionally, the motor nameplate should display the efficiency rating and other relevant information.

Q: What factors should be considered when selecting a NEMA Premium Efficiency Motor?

A: When selecting a NEMA Premium Efficiency Motor, factors to consider include the motor’s power and speed ratings, voltage and current requirements, application requirements, compatibility with existing equipment, environmental conditions, maintenance needs, and expected energy savings over the motor’s lifespan.

Q: Are NEMA Premium Efficiency Motors suitable for hazardous environments?

A: Some NEMA Premium Efficiency Motors are available with Class 1, Division 2 ratings, indicating that they are safe for use in hazardous locations where flammable gases, vapors, or liquids may be present. These motors are designed to meet strict safety standards for operation in potentially explosive atmospheres.

Q: How can I maximize the performance and lifespan of a NEMA Premium Efficiency Motor?

A: To maximize the performance and lifespan of a NEMA Premium Efficiency Motor, proper installation, regular maintenance, correct alignment, adequate ventilation, appropriate lubrication, and monitoring of operating conditions are essential. Following the manufacturer’s guidelines and recommendations is key to ensuring optimal motor performance.

Advantages and Disadvantages

NEMA Premium Efficiency Motors offers several advantages and disadvantages compared to standard efficiency motors. Here are some key points to consider:

Advantages:

Energy Savings: One of the primary advantages of NEMA Premium Efficiency Motors is their higher efficiency levels, which result in lower energy consumption and reduced operating costs over time. These motors are designed to convert electrical power into mechanical power more efficiently, leading to significant energy savings.

Cost-Effectiveness: While NEMA Premium Efficiency Motors may have a higher upfront cost compared to standard efficiency motors, the long-term energy savings and reduced operating expenses often outweigh the initial investment. These motors can offer a favorable return on investment over their lifespan.

Environmental Benefits: By consuming less energy to operate, NEMA Premium Efficiency Motors helps reduce greenhouse gas emissions and contributes to a more sustainable and environmentally friendly operation. Businesses that prioritize sustainability and energy efficiency can benefit from using these motors.

Improved Performance: NEMA Premium Efficiency Motors are designed for optimal performance, reliability, and durability. These motors often feature higher-quality components, precision engineering, and advanced technologies that enhance their overall performance and longevity.

Regulatory Compliance: Using NEMA Premium Efficiency Motors can help businesses comply with energy efficiency regulations, standards, and incentive programs that promote the adoption of efficient technologies. Many organizations and governments encourage or require the use of high-efficiency motors to reduce energy consumption and carbon footprint.

Disadvantages:

Higher Initial Cost: One of the main disadvantages of NEMA Premium Efficiency Motors is their typically higher upfront cost compared to standard efficiency motors. This initial investment may deter some buyers, especially those with budget constraints or cost-sensitive projects.

Specific Applications: NEMA Premium Efficiency Motors may not be necessary for all applications, especially those with low utilization or where energy savings are not a primary concern. In such cases, the higher cost of these motors may not be justified by the potential energy savings.

Compatibility: Upgrading to a NEMA Premium Efficiency Motor may require considerations regarding compatibility with existing equipment, control systems, and power supplies. It’s essential to ensure that the motor is suitable for the intended application and can work effectively within the existing setup.

Maintenance and Service: While NEMA Premium Efficiency Motors are designed for reliability and durability, they may require specialized maintenance and service compared to standard motors. Proper care, lubrication, and periodic inspections are essential to maximize the motor’s performance and lifespan.

In summary, while NEMA Premium Efficiency Motors offers significant advantages in terms of energy savings, performance, and environmental benefits, it’s important to weigh these benefits against the higher initial cost and specific considerations related to application, compatibility, and maintenance requirements. Businesses should assess their priorities, operating conditions, and long-term goals to determine whether investing in a NEMA Premium Efficiency Motor aligns with their objectives and budget constraints.

Downloads

Drawings

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.