Description

Introduction

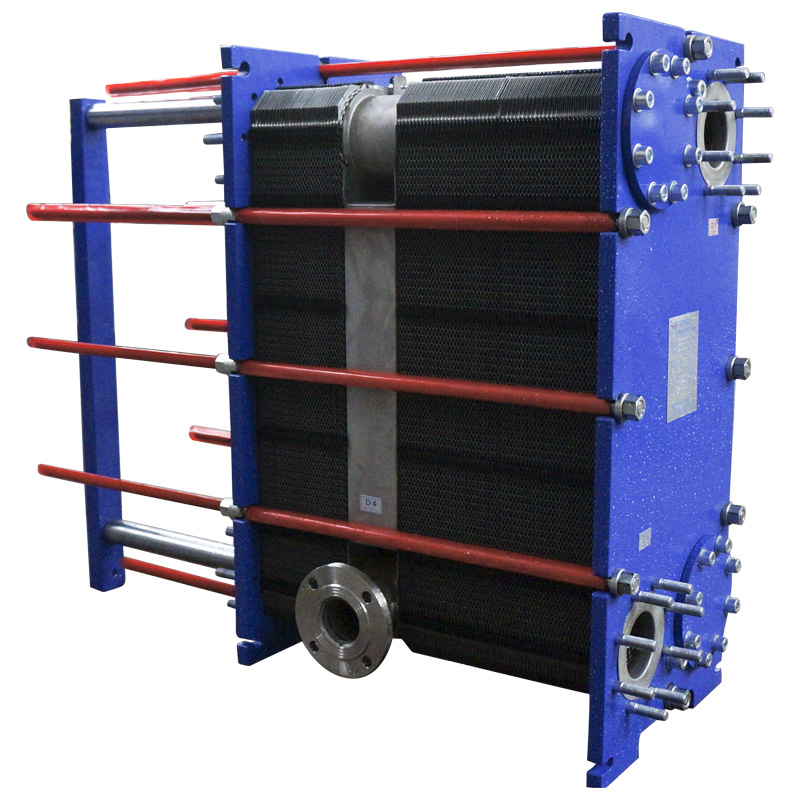

Plate and Frame Heat Exchangers are widely used in various industries for efficient heat transfer applications. This type of heat exchanger is designed to maximize surface area for enhanced heat transfer while maintaining a compact size. In this article, we will explore the working principles, construction, advantages, and applications of Plate and Frame Heat Exchangers.

Working Principles

The Plate and Frame Heat Exchangers operate on the principle of indirect heat transfer. It consists of a series of corrugated plates with alternating hot and cold fluids flowing through them. The hot and cold fluids are separated by these plates, allowing heat to transfer from one fluid to another through the plate walls. The corrugated pattern increases turbulence, promoting efficient heat transfer.

Construction of Plate and Frame Heat Exchangers

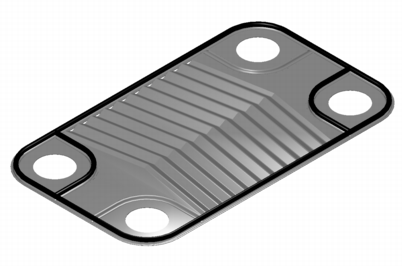

Plates

The plates used in Plate and Frame Heat Exchangers are typically made of stainless steel, titanium, or other suitable materials. They are corrugated to create turbulence in the fluid flow, maximizing the heat transfer area. Finally, gaskets are placed between the plates to ensure a tight seal and prevent any leakage.

Frame

The plates are held together by a frame, which provides structural support. In addition, the frame also houses the connections for the inlet and outlet of hot and cold fluids. This allows for easy installation and maintenance of the heat exchanger.

Gaskets

Between each pair of plates, there are gaskets to ensure that the fluids do not mix and to maintain the integrity of the flow channels. The gaskets are usually made of materials with good resistance to temperature and chemical exposure.

Inlet and Outlet Ports

The heat exchanger has ports for the inlet and outlet of each fluid. These ports allow the fluids to enter, flow through the appropriate channels formed by the plates, and exit the heat exchanger.

When the fluids flow through the alternating channels between the plates, heat is transferred from one fluid to the other. This type of heat exchanger is commonly used in industrial and HVAC applications due to its high efficiency, compact size, and ease of maintenance.

Conclusion

Plate and Frame Heat Exchangers offer a compact, efficient, and flexible solution for heat transfer applications across a wide range of industries. Also, their high heat transfer efficiency, easy maintenance, and versatile applications make them an essential component in numerous processes. Furthermore, by utilizing the principles discussed in this article, engineers and industry professionals can make informed decisions in selecting and designing Plate and Frame Heat Exchangers for their specific requirements.

Design of the Plate and Frame Heat Exchanger

The Plate Heat Exchanger (PHE) is a specialized design well suited to transferring heat between medium- and low-pressure fluids. Welded, semi-welded, and brazed heat exchangers are used for heat exchange between high-pressure fluids or where a more compact product is required.

Additionally, in place of a pipe passing through a chamber, there are instead two alternating chambers, usually thin in depth, separated at their largest surface by a corrugated metal plate. Moreover, the plates used in heat exchangers are obtained by one-piece pressing of metal plates. Finally, stainless steel is a commonly used metal for plates because of its ability to withstand high temperatures, its strength, and its corrosion resistance.

Sealing of the Plates

The plates are often spaced by rubber sealing gaskets which are cemented into a section around the edge of the plates. Also, the plates are pressed to form troughs at right angles to the direction of flow of the liquid. Furthermore, the liquid runs through the channels in the heat exchanger. These troughs are arranged so that they interlink with the other plates. Also, this causes it to form a channel with gaps of 1.3–1.5 mm between the plates.

Moreover, the plates are compressed together in a rigid frame to form an arrangement of parallel flow channels with alternating hot and cold fluids. Additionally, the plates produce an extremely large surface area, which allows for the fastest possible transfer. Finally, making each chamber thin ensures that the majority of the volume of the liquid contacts the plate, again aiding exchange.

The Troughs between the Plates

The troughs also create and maintain a turbulent flow in the liquid to maximize heat transfer in the exchanger. In addition, a high degree of turbulence can be obtained at low flow rates. Also, a high heat transfer coefficient can be achieved.

As compared to shell and tube heat exchangers, the temperature approach in plate heat exchangers may be as low as 1 °C. Whereas, shell and tube heat exchangers require an approach of 5 °C or more.

Therefore, for the same heat exchanged, the size of the heat exchangers is smaller. Also, this is because of the large heat transfer area by the plates.

Furthermore, the increase and reduction of the heat transfer area is simple in a plate heat exchanger. Finally, this is done through the addition or removal of plates.

Other heat exchanger types that may fit your requirement are Brazed Type and Shell and Tube.

Specifications

Plates

• Extensive range of heat transfer areas

• Varying plate thickness

• Available materials: SS304, SS316

Titanium, Hastelloy.

Gaskets

• Glued or Clipped on

• Easy assembly

• Available materials: EPDM, NBR, VITON

Here’s a general outline of the specifications you might include:

Heat Exchanger Type: Plate and Frame Heat Exchanger

Heat Exchanger Material: Stainless Steel (or specific material based on application requirements)

Design Pressure: Specify the design pressure in psi or bar

Design Temperature: Specify the design temperature range in °F or °C

Heat Transfer Area: Specify the heat transfer area in square feet or square meters

Number of Plates: Specify the number of plates in the heat exchanger

Plate Material: Specify the material of the plates, typically stainless steel

Plate Thickness: Specify the thickness of the plates in millimeters or inches

Plate Corrugation: Specify the type of corrugation pattern on the plates, if necessary

Gasket Material: Specify the gasket material, such as EPDM, Nitrile, Viton, etc.

Connection Type: Specify the connection type, such as tri-clamp, threaded, flanged, etc.

Flow Rate: Specify the maximum flow rate for each fluid in gallons per minute or liters per second

Fluid Compatibility: Specify the types of fluids the heat exchanger is compatible with, including any limitations

Industry Standards: Specify any industry standards or certifications the heat exchanger must meet, such as ASME, CE, or others

These specifications can be further tailored based on the specific requirements of your application, so be sure to include any additional parameters that are crucial for your particular use case.

If you need specific assistance tailoring the specifications for your application or have further questions, feel free to let me know!

Connection Ends

Connection Ends

Plate and frame heat exchangers can have various types of connection ends, which are designed to facilitate the integration of the heat exchanger into different industrial processes. Here are some common connection ends for plate and frame heat exchangers:

Threaded Connections: In some applications, the heat exchanger may have threaded connections, which allow for easy installation and removal using threaded pipe fittings.

Flanged Connections: Flanged connections are often used for larger plate and frame heat exchangers. Flanges provide a secure attachment point and allow for easy disassembly when needed for maintenance or cleaning.

Welded Connections: Welded connections are a more permanent type of connection often used in industrial settings. The heat exchanger may have weld-neck flanges or be directly welded into the system’s piping.

Quick Connect Fittings: Some plate and frame heat exchangers are designed with quick-connect fittings, such as tri-clamp or camlock fittings. These fittings enable rapid installation and removal for applications that require frequent disassembly.

Hose Connections: For certain applications, hose connections may be used to attach the heat exchanger to the fluid system. This type of connection provides flexibility and ease of maintenance.

Tri-clamp connections: Also known as tri-clover or sanitary connections are a common type of connection used in plate and frame heat exchangers, especially in industries where cleanliness and sterility are important, such as food, beverage, pharmaceutical, and biotech applications.

Tri-clamp connections consist of a gasket and clamp system, which provides a secure, leak-proof connection. Here’s a brief overview of the components of a tri-clamp connection:

Gasket

The gasket used in a tri-clamp connection is typically made of materials such as silicone, EPDM, or PTFE, which provide a hygienic and reliable seal. Additionally, the gasket fits between the two flange faces to prevent leakage and isolate the fluids within the system.

Clamp

The clamp is used to compress the gasket and create a tight seal between the two flange faces. Tri clamps are designed to be quickly and easily opened and closed, allowing for efficient disassembly and reassembly of the heat exchanger for maintenance or cleaning.

Tri-clamp connections are favored in industries where frequent disassembly and cleaning of the heat exchanger are necessary, as they enable rapid and tool-free assembly and disassembly, reducing downtime and maintenance costs.

The choice of connection end depends on factors such as the specific industrial process, space constraints, ease of maintenance, and the type of fluids being handled. Finally, it’s important to select the appropriate connection type to ensure a reliable and efficient operation of the plate and frame heat exchanger within the given system.

Advantages / Disadvantages

Plate and frame heat exchangers offer several advantages and disadvantages, which can vary based on the specific application and operational requirements. Here’s a breakdown of some key points:

Advantages

High Heat Transfer Efficiency: Plate and frame heat exchangers are designed to maximize heat transfer between fluid streams due to their large surface area and high turbulence created by the corrugated plates.

Compact Design: These heat exchangers have a very high surface area-to-volume ratio, making them compact and well-suited for applications where space is limited.

Versatility: Plate and frame heat exchangers can handle a wide range of fluids, pressures, and temperatures, making them suitable for diverse industrial processes.

Easy Maintenance: The nature of the design allows for easy disassembly and cleaning, as well as the ability to add or remove plates to adjust the heat exchanger’s performance to changing process requirements.

Cost-Effective: Plate and frame heat exchangers can offer lower installation, maintenance, and operating costs compared to other types of heat exchangers due to their efficiency, ease of maintenance, and versatility.

Disadvantages

Potential for Plate Fouling: Depending on the application, the narrow flow channels between plates can be susceptible to fouling from particulates or debris in the fluid streams, which may require more frequent maintenance.

Higher Pressure Drop: In some cases, plate and frame heat exchangers may result in a higher pressure drop compared to other types of heat exchangers, which could impact system performance and operating costs.

Limited to Low to Medium Viscosity Fluids: While plate and frame heat exchangers are versatile, they may be less suitable for handling highly viscous fluids compared to some other types of heat exchangers.

Mechanical Wear: The constant assembly and disassembly for maintenance may lead to potential mechanical wear and degradation of gaskets and other components over time.

Initial Cost: While they offer long-term savings, the initial purchase cost for a plate and frame heat exchanger may be higher than some other types of heat exchangers.

These factors should be carefully considered when evaluating the suitability of a plate and frame heat exchanger for a specific application. If you have further questions about this or any other topic, feel free to ask!

Q&A

Q: What is a plate and frame heat exchanger?

A: A plate and frame heat exchanger is a type of heat exchanger that uses a series of metal plates to transfer heat between two or more fluids. The plates are held together by a frame and bolts, and the fluids flow in alternating channels between the plates.

Q: What are the advantages of using a plate and frame heat exchanger?

A: Plate and frame heat exchangers offer high heat transfer efficiency, a compact design, versatility in handling different fluids and temperatures, easy maintenance, and cost-effectiveness.

Q: What are the potential disadvantages of a plate and frame heat exchanger?

A: Disadvantages may include potential plate fouling, higher pressure drop, limitations on handling highly viscous fluids, mechanical wear due to maintenance, and the potential for a higher initial purchase cost.

Q: Are plate and frame heat exchangers suitable for food and pharmaceutical applications?

A: Yes, plate and frame heat exchangers are often used in industries where cleanliness, sterility, and ease of cleaning are important, such as food, beverage, pharmaceutical, and biotech applications, particularly when equipped with sanitary connections like tri-clamp fittings.

Q: How do plate and frame heat exchangers compare to other types of heat exchangers?

A: Plate and frame heat exchangers excel in heat transfer efficiency, compactness, and versatility, but they may have specific limitations related to fouling, pressure drop, and fluid viscosity compared to other types such as shell and tube heat exchangers, which are more resilient to fouling and pressure changes.

I hope this Q&A provides a helpful overview of plate and frame heat exchangers. If you have more specific questions or need further assistance, feel free to ask!

Applications

Applications for Plate and Frame Heat Exchangers

Plate and Frame Heat Exchangers find applications in various industries, including

HVAC Systems

Plate and Frame Heat Exchangers are commonly used in heating, ventilation, and air conditioning systems. In summary, they efficiently transfer heat between the hot and cold fluids, contributing to the overall energy efficiency of the system.

Chemical Industry

Also, These heat exchangers are widely utilized in the chemical industry for applications such as heat recovery, product cooling, and condensation processes. Their compact size and high heat transfer efficiency make them an excellent choice for chemical processes.

Food and Beverage Industry

In addition, Plate and Frame Heat Exchangers are employed in food and beverage processing for pasteurization, sterilization, and cooling applications. Finally, they ensure a rapid and efficient heat transfer while maintaining product quality.

Power Generation

These heat exchangers are utilized in power plants for various heat recovery applications. They help in optimizing energy utilization and improving overall thermal efficiency.

Downloads

Drawings

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.