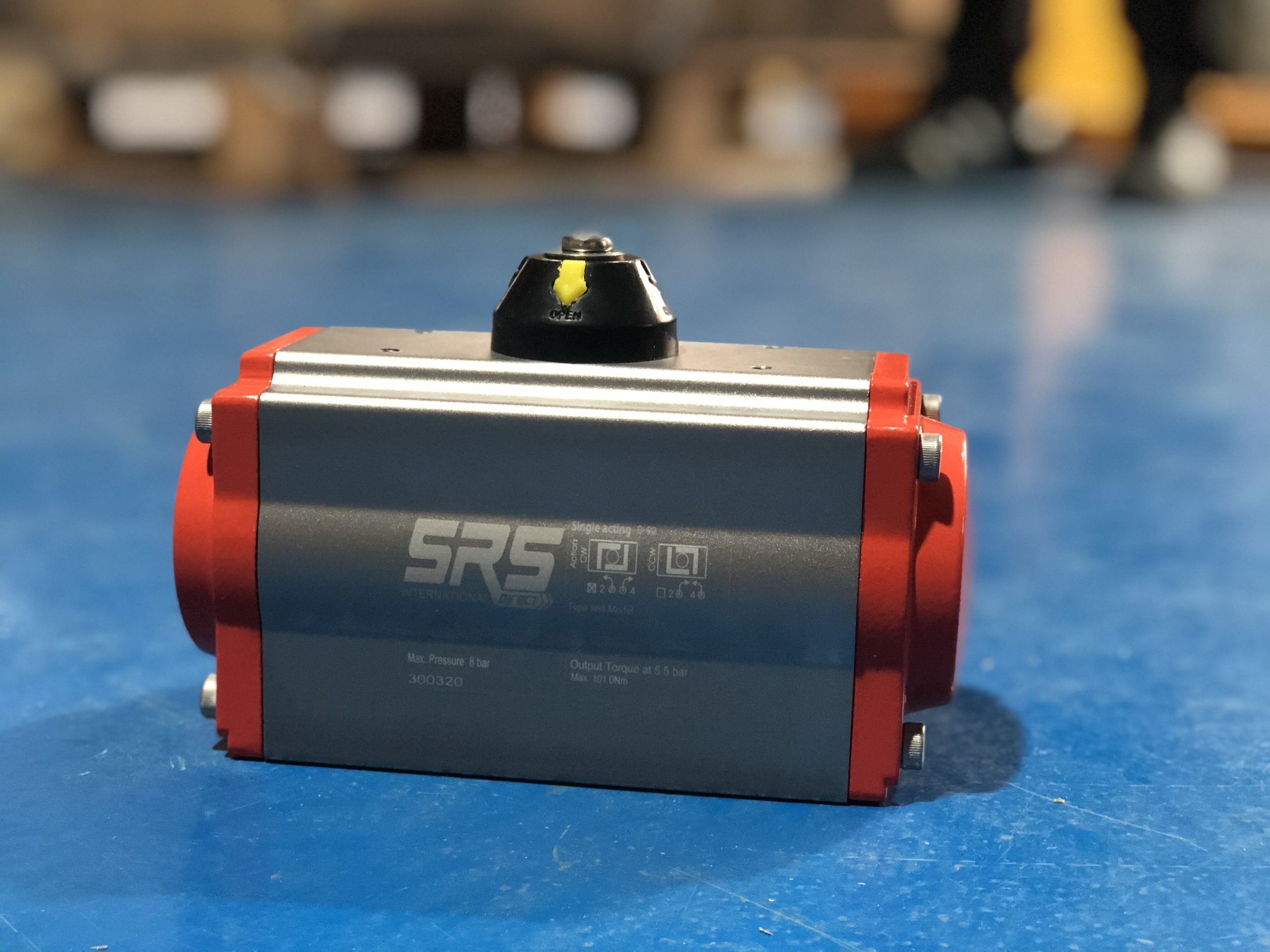

Description

A Pneumatic Actuator valve is a type of valve that is operated or controlled by air pressure. It is commonly used in various industries such as oil and gas, chemical, petrochemical, power generation, and water treatment, among others. The use of Pneumatic Actuator valves in these industries helps to control the flow of fluids or gases, allowing for efficient and safe operation of different processes.

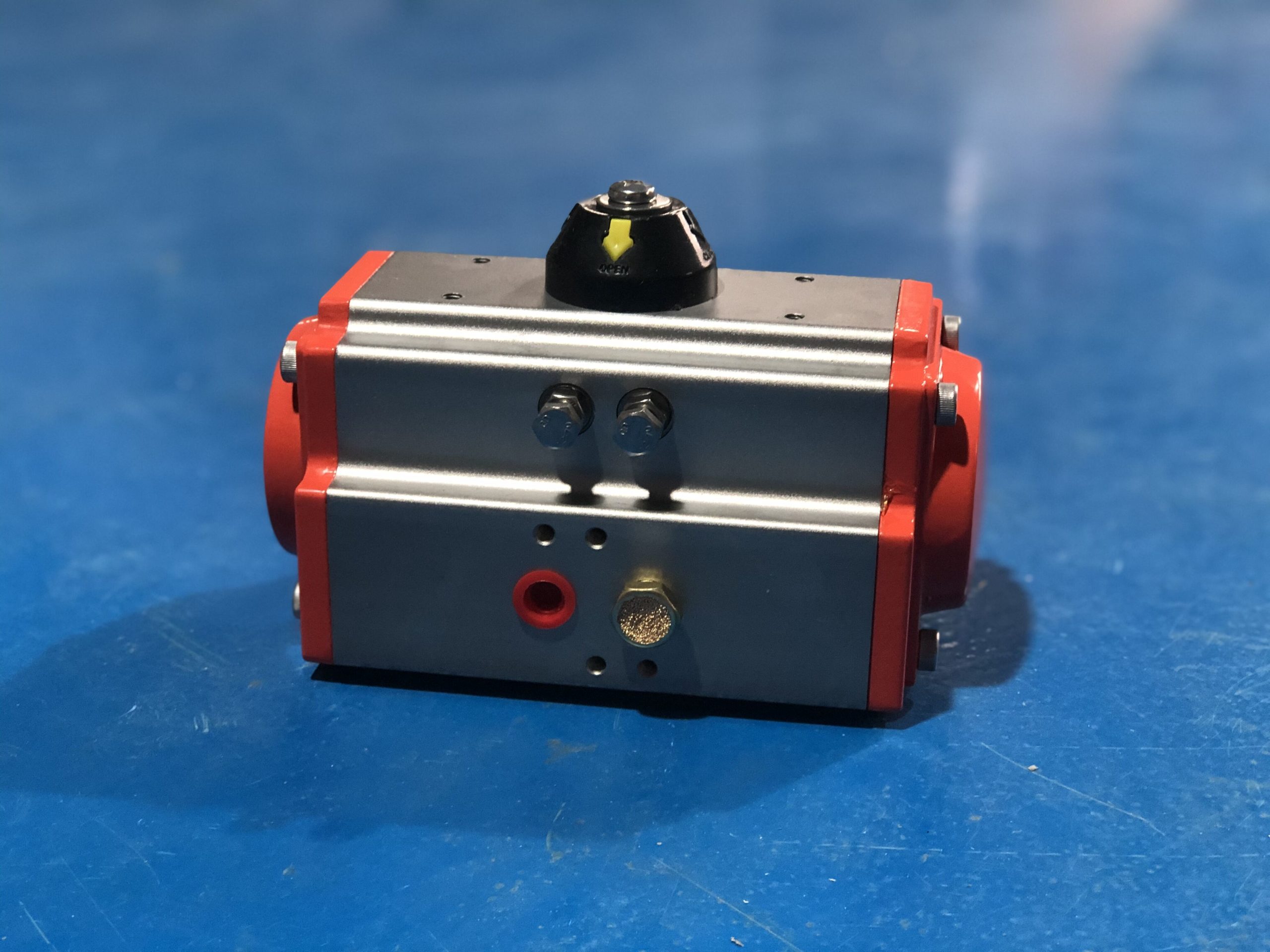

One of the key components of a pneumatic actuated valve is the actuator. The actuator converts the energy from compressed air into mechanical motion, which is used to open or close the valve. The actuator is typically powered by a pneumatic piston, which moves back and forth within a cylinder. When air pressure is applied to one side of the piston, it creates a force that moves the piston in one direction, causing the valve to open or close. When the air pressure is released, the actuator returns to its original position under the action of a spring or by the pressure of the fluid flowing through the valve.

Different Types

There are different types of pneumatic actuators used in pneumatic actuated valves, including diaphragm actuators, piston actuators, and rotary actuators. Diaphragm actuators are commonly used in small-sized valves and work by pressing a flexible diaphragm against the valve stem. Piston actuators, on the other hand, use a piston to open or close the valve. Rotary actuators are used in valves that require a rotating motion, such as ball valves or butterfly valves, and they operate by converting linear motion into rotary motion.

Pneumatic actuated valves offer several advantages over other types of valves. Firstly, they are relatively simple in design and offer reliable and efficient operation. They can be easily controlled and automated, allowing for accurate and precise control of fluid or gas flow. Additionally, pneumatic actuated valves are fast-acting and can be opened or closed within milliseconds, making them suitable for applications where quick response times are required.

Versatile

Furthermore, pneumatic actuated valves are versatile and can be used in a wide range of operating conditions, including high-pressure and high-temperature environments. They are also known for their durability and long service life, as they are less prone to wear and tear compared to other types of valves. Pneumatic actuators are resistant to harsh environmental conditions, such as extreme temperatures, corrosive fluids, and high levels of vibration.

In summary, Pneumatic Actuator valves play a crucial role in various industries by providing efficient and reliable control of fluid or gas flow. They are powered by compressed air, which is converted into mechanical motion by the actuator. Their simplicity, speed, versatility, and durability make them a popular choice for applications requiring precise and responsive control. Whether it is for controlling the flow of oil, gas, chemicals, or water, pneumatic actuated valves are an essential component in the industrial landscape.

Various Types

Pneumatic actuated valves come in various types, each designed to suit specific applications and requirements. Here are some common types of pneumatic actuated valves:

Globe Valve

Globe valves are widely used in industries where throttling or regulating fluid flow is required. They have a linear motion and offer good control over the flow rate. The actuator is used to move the valve plug or disc against the seat to control the flow by adjusting the size of the opening.

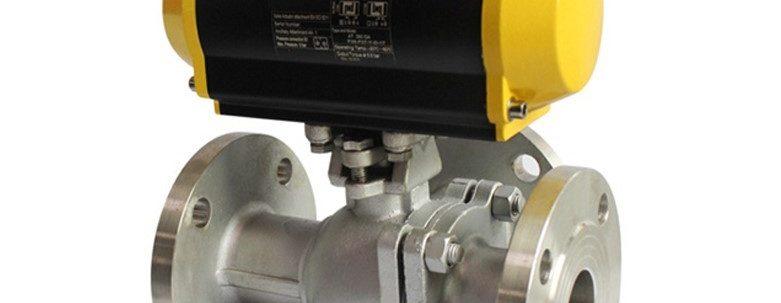

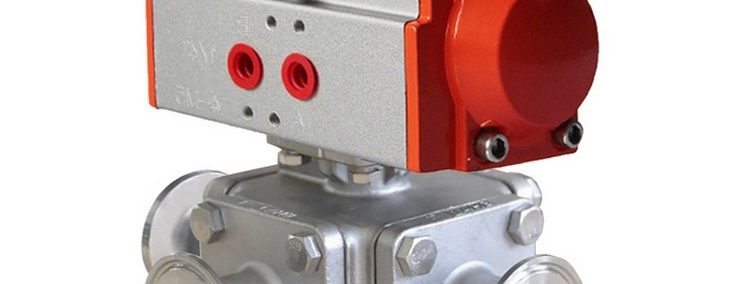

Ball Valve

Ball valves are known for their quick quarter-turn operation. They consist of a ball with a hole (bore) through it that can be rotated to align with the flow path for an open position or perpendicular to the flow path for a closed position. The actuator rotates the ball to control the flow.

Butterfly Valve

Butterfly valves use a disc that rotates on a shaft perpendicular to the flow path. When the disc is turned parallel to the flow path, it allows fluid to flow through and when turned perpendicular, it blocks the flow. The actuator rotates the disc to open or close the valve.

Diaphragm Valve

Diaphragm valves have a flexible diaphragm that acts as a seal to control fluid flow. The actuator applies pressure to the diaphragm, causing it to move up and down, thus opening or closing the valve. Diaphragm valves are commonly used in applications where the fluid should not come in contact with the valve body.

Pinch Valve

Pinch valves utilize a sleeve or tube that can be compressed or pinched by the actuator. When the sleeve is compressed, it blocks the flow of fluid, and when it is released, the fluid flows. Pinch valves are often used in applications where the fluid may contain solid particles or where the flow needs to be completely shut off.

Plug Valve

Plug valves have a conical or cylindrical plug inside the valve body that can be rotated to block or allow fluid flow. The actuator rotates the plug to control the flow. Plug valves are commonly used in applications where there is a need for tight shut-off or for handling viscous fluids.

These are just a few examples of pneumatic actuated valves. There are also other types available, such as check valves, needle valves, and solenoid valves, each with its own unique design and function. The selection of the right valve type depends on factors such as the nature of the fluid, flow control requirements, operating conditions, and the application itself.

Advantages of Pneumatic Actuated Valves

Quick and Responsive

Pneumatic actuated valves offer fast response times, allowing for rapid opening and closing of the valve. This quick operation is particularly beneficial in applications that require immediate control or emergency shutdowns.

Versatility

Pneumatic actuated valves are versatile and can be used with a wide range of fluids, including liquids, gases, and even abrasive or corrosive media. They are suitable for various pressures and temperatures, making them adaptable to different industrial processes.

Simple and Reliable

Pneumatic actuated valves have a simple design, with fewer moving parts compared to other types of valves. This simplicity contributes to their reliability, as fewer components mean lower chances of failure or breakdown. They have a long service life and require minimal maintenance.

Precise Control

Pneumatic actuated valves provide accurate and precise control over the flow rate, allowing for precise regulation in industrial processes. The linear or rotary motion of the actuator translates into precise adjustments of the valve opening, ensuring the desired flow control.

Safety

Pneumatic actuated valves are considered safe to use, especially in hazardous environments. They can be easily integrated into safety systems, and in case of a power failure, they typically return to a fail-safe position (e.g., closed) due to spring action or fluid pressure.

Disadvantages of Pneumatic Actuated Valves

Limitations in High-Speed Applications

While pneumatically actuated valves provide fast response times, they may have limitations in extremely high-speed applications. In processes requiring ultra-high-speed control, other valve types like electric or hydraulic valves may be more suitable.

Limited Control Range

The control range of pneumatic actuated valves is limited compared to other valve types. While they offer precise control over moderate flow rates, they may not perform as effectively when dealing with high flow rates or very low flow rates.

Energy Consumption

Pneumatic actuated valves require a supply of compressed air, which means they rely on energy consumption for operation. In some cases, the energy required for generating compressed air can add to the overall energy consumption of the system.

Noise and Vibrations

Pneumatic actuators can generate noise and vibrations during operation, which can be a concern in certain applications or environments. Additional measures may be required to mitigate these effects, such as employing noise-reducing accessories or isolating the valve from the surrounding structure.

Initial Cost

Pneumatic actuated valves may have a higher initial cost compared to manual valves or some other types of automated valves. However, their long service life, reliability, and ease of maintenance can compensate for the initial investment in the long run.

It’s important to consider the specific application requirements and weigh the advantages against the limitations when selecting pneumatic actuated valves for a particular application. Consulting with industry experts and valve manufacturers can provide valuable guidance in determining the most suitable valve solution.

Industries Served

Pneumatic actuated valves find application in a wide range of industries due to their versatile and efficient control capabilities. Here are some of the industries where pneumatic actuated valves are commonly used:

Oil and Gas

Pneumatic actuated valves are extensively used in the oil and gas industry for controlling the flow of crude oil, natural gas, and various petroleum products in pipelines, refineries, and storage terminals. They are particularly beneficial in applications that require quick and accurate response times.

Chemical and Petrochemical

Pneumatic actuated valves play a crucial role in the chemical and petrochemical industry for regulating the flow of various chemicals, solvents, and gases. They are used in processes such as fluid handling, mixing, blending, and controlling reaction rates.

Power Generation

In power plants, pneumatic actuated valves find application in controlling the flow of steam, water, and fuel. They are used in boiler systems, turbine control, cooling water systems, and other power generation processes where precise control and reliability are essential.

Water and Wastewater Treatment

Pneumatic actuated valves are widely used in water treatment plants for controlling the flow of water, chemicals, and sludge in various treatment processes. They are also employed in wastewater treatment plants to manage the flow of sewage, slurry, and other fluids.

Pharmaceutical and Biotechnology

Pneumatic actuated valves are utilized in pharmaceutical and biotechnology industries for controlling the flow of fluids in processes such as drug manufacturing, fermentation, filtration, and purification. They provide strict sanitary control and precision in critical manufacturing processes.

Food and Beverage

Pneumatic actuated valves play a vital role in the food and beverage industry, where they are used to control the flow of ingredients, liquids, and gases in production lines. They are employed in applications including mixing, filling, packaging, and sterilization processes.

HVAC and Building Automation

Pneumatic actuated valves are utilized in heating, ventilation, and air conditioning (HVAC) systems. They are used for regulating the flow of heating and cooling fluids. They are also employed in building automation systems to control the flow of air. In addition to that, water, and other utilities within commercial and residential buildings.

Mining

Pneumatic actuated valves are used in the mining industry for controlling the flow of slurry, chemicals, and water. It is also used in various mining processes, including mineral extraction, ore processing, and tailings management.

These are just a few examples of the industries where pneumatic actuated valves are commonly used. Their versatility, reliability, and ease of control make them an essential component in numerous industrial applications.

Principle of operation for Pneumatic Actuator

Also, the valves require little pressure to operate and usually double or triple the input force. The larger the size of the piston, the larger the output pressure can be. Having a larger piston can also be good if the air supply is low, allowing the same forces with less input.

In addition, these pressures are large enough to crush objects in the pipe. On 100 kPa input, you could lift a small car (upwards of 1,000 lbs.) easily, and this is only a basic, small pneumatic valve. However, the resulting forces required of the stem would be too great and cause the valve stem to fail.

Valve Stem and Valve Plus for the Pneumatic Actuator

This pressure is transferred to the valve stem, which is connected to either the valve plug (see plug valve), butterfly valve, etc. Also, larger forces are required in high-pressure or high-flow pipelines to allow the valve to overcome these forces, and allow it to move the valves moving parts to control the material flowing inside.

Finally, the valve input is the “control signal.” This can come from a variety of measuring devices, and each different pressure is a different set point for a valve. Finally, a typical standard signal is 20–100 kPa. For example, a valve could be controlling the pressure in a vessel. It has a constant out-flow, and a varied in-flow (varied by the actuator and valve).

Transmitters for Pneumatic Actuators

Furthermore, A pressure transmitter will monitor the pressure in the vessel and transmit a signal from 20–100 kPa. At 20 kPa there is no pressure. At 100 kPa there is full range pressure (can be varied by the transmitters calibration points).

Also, as the pressure rises in the vessel, the output of the transmitter rises. It is this increase in pressure that is sent to the valve. In turn, this is what causes the valve to stroke downward, and start closing the valve.

In addition, this will also decrease flow into the vessel, reducing the pressure in the vessel. Finally, It is because the excess pressure is evacuated through the outflow. Also, this is called a direct-acting process.

| Spring return pneumatic actuator directly mounted on a 2-way stainless steel sanitary ball valve | |||||||

| – Specification of the SR pneumatic actuator refers to spring return | |||||||

| – Features of 2-way, 3-piece stainless steel sanitary full port ball valve: | |||||||

| * Full port sizes | |||||||

| * ISO 5211 mounting pad | |||||||

| * Working pressure 1000 psi WOG (1/2″ to 3″) 800 psi WOG (2-1/2″ to 3″) | |||||||

| * Temperature range -60 to 450 degrees Fahrenheit | |||||||

| * Anti-Static |

In Conclusion, if this type of Pneumatic Actuator does not meet your requirements, pls contact SRS or see our other products below

Reviews

There are no reviews yet.