Description

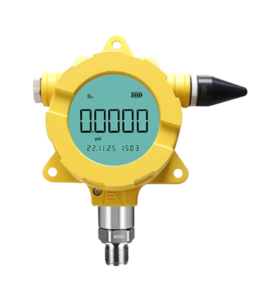

A wireless pressure transmitter is a sophisticated device utilized in various industries for measuring, monitoring, and transmitting pressure readings wirelessly. It consists of several components working together seamlessly to provide accurate and reliable pressure data in real time.

A wireless pressure transmitter is a sophisticated device utilized in various industries for measuring, monitoring, and transmitting pressure readings wirelessly. It consists of several components working together seamlessly to provide accurate and reliable pressure data in real time.

At the core of the wireless pressure transmitter is the pressure sensor. This sensor detects physical pressure applied to it and converts it into an electrical signal. The sensor’s accuracy, range, and sensitivity are crucial factors that determine the overall precision of the pressure readings. Various types of pressure sensors, including piezoelectric, strain gauge, capacitive, or piezoresistive sensors, are used based on the specific application.

The pressure sensor connects to the transmitter unit, which processes the electrical signal from the sensor. The transmitter unit typically includes a signal conditioning circuitry to amplify and filter the signal, ensuring that it is accurate and reliable. Additionally, it may contain temperature compensation mechanisms to account for temperature variations that could affect pressure readings.

Key Features

One of the key features of a wireless pressure transmitter is its wireless communication capability. This allows the device to transmit pressure readings to a receiver or monitoring system without the need for physical wires. Various wireless communication protocols can be used, such as Zigbee, Bluetooth, LoRa, or 4G LTE, each offering unique advantages in terms of range, power consumption, data rate, and reliability.

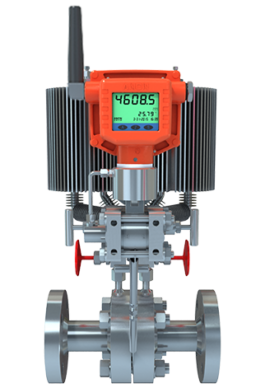

In industrial settings, organizations frequently use wireless pressure transmitters in remote or hazardous locations where wired connections are impractical or unsafe. They provide a cost-effective and efficient solution for monitoring pressure in systems like pipelines, tanks, hydraulic systems, and industrial machinery.

A central monitoring system can receive the data transmitted wirelessly from the pressure transmitter. Access can also occur through mobile devices like smartphones or tablets. This real-time data access enables quick decision-making and predictive maintenance. Furthermore, it is real-time with remote monitoring of pressure conditions.

Robust and Durable for a Wireless Pressure Transmitter

Designers create wireless pressure transmitters to be robust, durable, and capable of withstanding harsh environmental conditions. Moreover, such conditions as extreme temperatures, humidity, and vibrations. Manufacturers often make enclosures out of rugged materials like stainless steel. Other materials are industrial-grade plastics to ensure protection against external elements.

Power source considerations are also crucial for wireless pressure transmitters. Depending on the application requirements, batteries may power them. Solar panels or energy harvesting systems can also power them. Implementing low-power design strategies often ensures extended battery life and minimizes maintenance needs.

In conclusion, wireless pressure transmitters play a vital role in modern industrial processes by providing accurate, reliable, and real-time pressure data wirelessly. Their advanced sensor technology and wireless communication capabilities are essential. They are also robust design, and power efficiency make them essential components in industrial automation, IoT applications, and remote monitoring systems.

Specification

Product Features

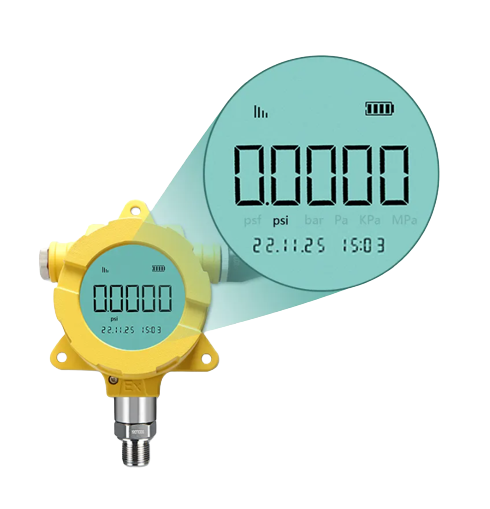

11 units display: Pa, kPa, MPa, psi, bar, mbar, kgf/cm2, inH2O, mmH2O, inHg, mmHg

0.025 ~ 7200 seconds per time acquisition speed

4.1V rechargeable battery

100 thousand data storage capacity, easy to carry and collect data

Magnetic induction button design

Pressure percentage bar charts show

Signal isolation technique, anti-electromagnetic interference, and RFI technique

Zero stable technology, automatic temperature compensation technology

Product application

Oil and gas pressure data collection, storage, and analysis

Urban water network, heat supply network, and gas network pressure data collection, storage, and analysis Lab pressure test and analysis. Verify pressure (differential pressure) transmitter, precision pressure gauge, general pressure gauge measuring corollary software of pressure monitors and other pressure instruments, accuracy grade can arrive at 0.05, which can meet high precision pressure acquisition can work well in corrosive, impact, and versatility environments meet the lab and industrial field high precision pressure acquisition requirement

Product Parameters:

Display unit: Pa, kPa, MPa, psi, bar, mbar, kgf/cm2, inH2O, mmH2O, inHg, mmHg

Measuring Range:

Gage Pressure: -0.1MPa~260MPa

Differential Pressure: 0~3.5MPa

Absolute Pressure: 0~60MPa

Accuracy grade: 0.05 0.1 0.2 0.5

Communication: RS485, USB

Span shift: Suggested less than 3:1

Power supply mode: Build-in one 4.1V rechargeable battery

Picking rate:

| Picking rate |

50times per second |

40times per second |

30times per second |

| Time range setting |

0.02-140s per time |

0.025-180s per time |

0.033-240s per time |

| Picking rate |

20times per second |

10times per second |

one time per second |

| Time range setting |

0.05-360s per time |

0.1-720s per time |

1-7200s per time |

Stability Performance: +0.1% FS per year

Battery life:

| Picking rate |

4 times per second |

2 times per second |

1 time per second |

1 time per 2s |

| Lifetime |

2.8 years |

5 years |

5.5 years |

7 years |

| Picking rate |

1 time per 3s |

1 time per 4s |

1 time per (5-10)s |

| Lifetime |

9 years |

More than 10 years |

More than 10 years |

Operating temperature: -30℃~70℃

Relative humidity: <90%

Barometric pressure: 86-106KPa

Others:

Calibration reference operating temperature 20℃±2℃

0.05 accuracy requires an operating temperature of 0-50℃

Medium Temperature:

General temperature range (-40~120)℃

Wide temperature range (-60~150)℃

Display mode: Five figures dynamic display and percentage bar chart

Protection Degree: IP65

Classification: Exdl: ExiaIICT4 Ga

Overload Pressure: 1.5-3 times of measuring range, depending on the measuring range

Software configuration:

SRS View R-SD digital instrument test software displaying instrument data, automatic recording, automatic drawing pressure curve and deriving to Excel, reading, printing, and storage.

Process Connection:

Metric M20×1.5、M14×1.5、M14×1

US/UK Standard: G1/2, G3/4, G1/8, G3/8, NPT 1/2, NPT 1/4, NPT 1/8

Communication Options

LoRa (Long Range), NB-IoT (Narrowband IoT), and 4G are different wireless communication technologies, each with unique characteristics and use cases:

LoRa

- LoRa is a low-power, long-range wireless communication technology designed for connecting battery-operated devices over long distances.

- It operates in the unlicensed radio spectrum, offering long-range connectivity with minimal power consumption, making it suitable for Internet of Things (IoT) applications such as smart city infrastructure, agriculture, and industrial monitoring.

- LoRa is known for its ability to penetrate obstacles and provide reliable communication in challenging environments.

NB-IoT

- NB-IoT, or Narrowband IoT, is a Low Power Wide Area Network (LPWAN) technology designed for long-range, low-power IoT applications using licensed cellular bands.

- It provides deeper coverage compared to traditional cellular networks and is optimized for efficient data transmission from a large number of IoT devices.

- NB-IoT is well-suited for applications that require long battery life, such as asset tracking, smart meters, and remote monitoring.

4G

- 4G is a standard for wireless broadband communication, providing high-speed data transmission and low latency for mobile devices and applications.

- It operates in licensed bands and is commonly used for high-bandwidth applications, such as mobile internet access, video streaming, and voice communication.

- 4G offers fast and reliable data connectivity, making it suitable for applications that require real-time data transmission and high-speed internet access.

In summary, LoRa and NB-IoT are tailored for low-power, long-range IoT applications, with the former working in unlicensed spectrum and the latter leveraging licensed cellular bands. On the other hand, 4G provides high-speed, high-bandwidth communication for mobile and data-centric applications. The choice of technology depends on the specific requirements of the application, such as range, power consumption, and data transmission speed.

Installation

Installing a wireless pressure transmitter involves several crucial steps to ensure accurate pressure measurements and reliable wireless communication. Here is a comprehensive guide to the installation procedure:

Planning and Preparation

Review Manufacturer’s Documentation: Begin by thoroughly reading the installation manual provided by the manufacturer. This document will include specific instructions, installation requirements, and safety precautions for your particular model.

Gather Necessary Tools and Equipment: Assemble all required tools and materials, including wrenches, pipe fittings, sealants, a mounting bracket (if applicable), and any power sources or batteries.

Select Installation Location: Choose a location for the transmitter that provides accurate pressure readings and optimal wireless signal strength. The site should be accessible, free from excessive vibrations, and protected from extreme temperatures and environmental conditions.

System Preparation

Shut Down the System: If installing the transmitter on a live system, ensure that the system is shut down and depressurized to avoid any hazards and ensure safety.

Drain the System: If necessary, drain the fluid or gas from the pipeline where the transmitter will be installed. This step helps prevent spills and ensures a clean installation environment.

Installing the Pressure Transmitter

Prepare the Connection Point: Ensure that the connection point on the pipeline or pressure vessel is clean and free from debris, corrosion, or old sealant. This preparation is crucial for a proper seal and accurate readings.

Install the Pressure Transmitter:

- Threaded Connection: If the transmitter uses a threaded connection, apply appropriate sealant to the threads to prevent leaks. Screw the transmitter into the pipeline or pressure port and tighten it securely with a wrench.

- Flanged Connection: For flanged transmitters, align the transmitter with the flanges, place gaskets if required, and secure it with bolts. Tighten the bolts evenly in a cross pattern to ensure a proper seal.

Ensure Proper Alignment: Make sure the transmitter is correctly aligned with the pipeline or pressure vessel to avoid mechanical stress and potential damage.

Wireless Communication Setup

Power the Transmitter: Insert the batteries or connect the power source as specified by the manufacturer. Ensure that the power supply is stable and meets the transmitter’s requirements.

Configure Wireless Settings: Follow the manufacturer’s instructions to configure the wireless communication settings. This may involve pairing the transmitter with a receiver, setting up network connections, or configuring communication protocols.

Test Wireless Connectivity: Verify that the transmitter is successfully communicating with the receiver or control system. Check for signal strength and ensure there are no obstructions or interference affecting the wireless signal.

Calibration and Testing

Calibrate the Transmitter: Perform the calibration procedures as outlined in the manufacturer’s documentation. Calibration is essential to ensure accurate pressure readings.

Conduct Functional Tests: Gradually reintroduce pressure to the system and observe the transmitter’s readings. Check for accuracy, consistency, and any signs of leaks or malfunctions.

Verify Data Transmission: Confirm that the data from the transmitter is correctly transmitted and displayed on the receiver or monitoring system. Ensure that the data aligns with expected pressure values.

Final Checks and Documentation

Inspect the Installation: Perform a final inspection to ensure that the transmitter is securely installed, there are no leaks, and the wireless communication is stable.

Document the Installation: Record all installation details, including the location of the transmitter, configuration settings, calibration results, and any observations from the testing phase. This documentation will be useful for future reference and maintenance.

Provide Training: If necessary, provide training or instructions to relevant personnel on how to operate, monitor, and maintain the wireless pressure transmitter.

Ongoing Maintenance and Monitoring

Schedule Regular Inspections: Plan regular inspections to ensure the transmitter remains in good working condition. Check for any signs of wear, damage, or calibration drift.

Monitor Performance: Continuously monitor the performance of the transmitter and wireless communication. Address any issues promptly to maintain accurate pressure measurements and reliable data transmission.

By following these installation procedures, you can ensure that your wireless pressure transmitter is set up correctly, functions effectively, and provides reliable pressure measurements for your system. Regular maintenance and monitoring will help maintain optimal performance and extend the lifespan of the equipment.

Maintenance

Maintaining a wireless pressure transmitter is essential for ensuring accurate pressure readings and reliable performance. Here is a comprehensive guide to the maintenance procedures:

Routine Inspections

Visual Inspection: Regularly inspect the pressure transmitter for signs of physical damage, such as cracks, corrosion, or loose fittings. Ensure that the transmitter and its components are secure and intact.

Wireless Signal Check: Verify that the wireless communication between the transmitter and the receiver or control system is functioning properly. Check for consistent signal strength and ensure there are no obstructions or sources of interference affecting the signal.

Leak Detection: For transmitters installed on pipelines or pressure vessels, inspect the connection points for any signs of leaks. Look for fluid or gas escaping around the transmitter or connection fittings.

Cleaning

Schedule Cleaning: Depending on the operating environment and the type of fluid or gas being measured, schedule cleaning intervals to prevent build-up of contaminants that could affect performance.

Cleaning Procedure:

- Shut Down System: Ensure that the system is turned off and depressurized before cleaning.

- Remove the Transmitter: If necessary, carefully remove the transmitter from its installation point.

- Clean the Transmitter: Use a non-abrasive cleaner and a soft cloth to clean the transmitter’s exterior. Avoid using harsh chemicals or solvents that might damage the equipment.

- Reinstall: After cleaning, reinstall the transmitter, ensuring all connections are secure and properly aligned.

Calibration

Regular Calibration: Follow the manufacturer’s guidelines for calibration frequency. Regular calibration is crucial for maintaining measurement accuracy.

Calibration Procedure:

- Verify Calibration Schedule: Check the recommended calibration intervals provided by the manufacturer.

- Use Calibration Standards: Perform calibration using standard pressure references to ensure accuracy.

- Adjust Settings: If necessary, adjust the transmitter’s settings to match the calibration standards.

Battery and Power Management

Check Power Sources: Regularly inspect the battery or power source to ensure it is functioning properly. For battery-powered models, monitor battery life and replace batteries as needed.

Power Connections: Ensure that all power connections are secure and free from corrosion or damage. For wired power sources, verify that connections are intact and reliable.

Energy Harvesting Systems: For transmitters with energy-harvesting features (e.g., solar panels), check that the energy source is clean and unobstructed.

Firmware and Software Updates

Check for Updates: Periodically check for any firmware or software updates from the manufacturer. Updates can improve performance, fix bugs, or add new features.

Install Updates: Follow the manufacturer’s instructions to download and install updates. Schedule updates during maintenance windows to minimize operational disruptions.

Data Management

Review Data Logs: Regularly review the data logs collected by the transmitter for any anomalies or trends that might indicate issues.

Backup Data: Ensure that data is backed up regularly, especially if integrated with cloud-based systems or data management platforms.

Troubleshooting

Address Performance Issues: If the transmitter shows irregular performance or inaccuracies, troubleshoot using the manufacturer’s guidelines. Common issues might include signal interference, calibration drift, or sensor malfunctions.

Contact Support: For persistent problems or complex issues, contact the manufacturer’s technical support team for further assistance.

Documentation

Record Maintenance Activities: Document all maintenance activities, including inspections, cleaning, calibrations, and repairs. This record helps track the history of the transmitter and plan future maintenance.

Update Maintenance Logs: Keep detailed logs of any changes or updates made to the transmitter’s configuration, software, or hardware.

Training and Best Practices

Train Personnel: Ensure that all personnel responsible for operating or maintaining the transmitter are properly trained and understand the maintenance procedures.

Follow Best Practices: Adhere to industry best practices for handling and maintaining pressure transmitters, including avoiding exposure to harsh conditions that could damage the equipment.

By adhering to these maintenance procedures, you can ensure that your wireless pressure transmitter continues to operate accurately and reliably, providing essential pressure measurements and contributing to the overall efficiency and safety of your system.

Q&A

Q: What are the advantages of using wireless pressure transmitters over wired ones?

A: Wireless pressure transmitters offer flexibility in installation, reduced maintenance costs, and the ability to easily reposition or add more transmitters without the need for new wiring. They also provide the capability for remote monitoring and data collection.

Q: How secure are wireless pressure transmitters’ communication methods?

A: Most modern wireless pressure transmitters employ encryption and authentication protocols to ensure secure communication. This helps protect the integrity and confidentiality of the transmitted data.

Q: Can wireless pressure transmitters work in harsh industrial environments?

A: Yes, many wireless pressure transmitters are designed to withstand extreme temperatures, high pressures, and harsh environmental conditions commonly found in industrial settings.

Q: Are wireless pressure transmitters compatible with existing control systems?

A: Wireless pressure transmitters are designed to integrate seamlessly with existing control systems, including PLCs, SCADA systems, and DCS platforms. Compatibility may vary based on the communication protocol used.

Q: What is the typical range of wireless pressure transmitters?

A: The range of wireless pressure transmitters can vary based on the communication method and environmental factors. Generally, they can have a range from a few hundred feet to several miles, depending on the technology used and any potential obstructions.

Q: Can wireless pressure transmitters be used for mobile applications?

A: Yes, some wireless pressure transmitters are designed for mobile applications, utilizing cellular communication or other mobile network technologies to transmit data from remote or moving assets.

Q: How do wireless pressure transmitters handle power requirements?

A: Wireless pressure transmitters may use batteries or energy-harvesting methods for power. Some are designed for long battery life, while others can harvest energy from the environment to power themselves.

Q: What are the key maintenance considerations for wireless pressure transmitters?

A: Regular inspection of power sources, confirming secure communication, and ensuring environmental protection are important for maintaining wireless pressure transmitters. Additionally, periodic checks of signal strength and data integrity are advisable.

Q: Are there limitations to using wireless pressure transmitters?

A: While wireless pressure transmitters offer numerous benefits, factors such as signal interference, range limitations, and potential security vulnerabilities need to be considered when implementing wireless solutions.

Advantages / Disadvantages

Advantages

Wireless pressure transmitters offer several advantages over their wired counterparts. They provide flexibility in terms of installation, enabling the monitoring of pressure in hard-to-reach or hazardous locations. The absence of physical wiring simplifies maintenance and reduces the risk of damage or interference with other equipment. Wireless transmitters can also be easily repositioned or relocated as needed.

In terms of maintenance and management, wireless pressure transmitters may incorporate self-diagnostic capabilities for identifying faults or irregularities in the measurement process. They may also support over-the-air (OTA) firmware updates, allowing for easy software upgrades and ensuring compatibility with evolving wireless protocols or security standards.

In conclusion, a wireless pressure transmitter is a sophisticated device that enables remote and wireless monitoring of pressure. It incorporates components such as a pressure sensor, signal conditioning circuitry, microcontroller, and wireless transceiver, which work together to measure, process, and transmit pressure data. The flexibility, convenience, and range of applications make wireless pressure transmitters invaluable in various industries, from industrial automation to oil and gas, and beyond.

Disadvantages

While wireless pressure transmitters offer numerous advantages, they also come with a few disadvantages. Here are some common drawbacks associated with wireless pressure transmitters:

Limited Range

Wireless pressure transmitters typically have a limited wireless range, especially when compared to wired counterparts. The range can be affected by various factors such as obstacles, interference, and the transmitting power of the device. In situations where monitoring points are located far apart or in challenging environments, additional repeaters or signal boosters may be necessary to ensure reliable communication.

Potential Interference

Wireless communication can be susceptible to interference from other wireless devices operating on similar frequency bands. This interference can affect the reliability and accuracy of the transmitted pressure data. Careful frequency planning and selection of wireless technology with good interference resistance can help mitigate the impact of interference, but it remains a challenge in certain environments.

Power Dependency

Wireless pressure transmitters require a power source to operate, whether in the form of batteries or an external power supply. Battery-powered transmitters may introduce concerns regarding battery life and the need for regular replacement or recharging. Power consumption also needs to be optimized to prolong the operational lifespan of the transmitter.

Potential Signal Loss or Disruption

Wireless signals can be susceptible to signal loss or disruption due to environmental factors such as obstacles, electromagnetic interference, or even wireless signal fading. In certain environments where there are significant obstructions or high interference levels, maintaining a reliable wireless connection can be challenging.

Security Risks

Wireless communication comes with inherent security risks. Without proper encryption and authentication protocols, transmitted pressure data can be vulnerable to interception, tampering, or unauthorized access. Implementing robust security measures, such as encryption protocols and secure communication channels, is crucial to ensure the confidentiality and integrity of the transmitted data.

Higher Cost

Wireless pressure transmitters generally come at a higher cost compared to their wired counterparts. The additional wireless communication components, such as transceiver modules and associated electronics, contribute to the overall cost of the device. Moreover, the need for additional repeaters or signal boosters may also incur extra expenses in large or complex installations.

Maintenance Requirements

Wireless pressure transmitters require periodic maintenance and monitoring to ensure proper functionality and system integrity. This includes monitoring battery levels, checking wireless signal strength, and verifying communication performance. Additionally, firmware updates may be necessary to address security vulnerabilities or to improve system performance.

It is worth noting that while these disadvantages exist, wireless pressure transmitters continue to be widely used in various applications due to their numerous benefits and the ongoing advancements in wireless communication technologies. The disadvantages can often be addressed through careful planning, proper installation, and the implementation of appropriate measures to mitigate the associated risks.

Applications

Wireless pressure transmitters are versatile devices that can be used in a variety of applications across different industries. Some common applications include:

Industrial Automation: Wireless pressure transmitters are used in industrial automation systems to monitor and control pressure in manufacturing processes, ensuring optimal performance and efficiency.

Oil and Gas: In the oil and gas industry, wireless pressure transmitters are utilized for monitoring pressure in pipelines, wellheads, and storage tanks, helping to ensure safe and reliable operations.

HVAC Systems: Wireless pressure transmitters are used in heating, ventilation, and air conditioning (HVAC) systems to measure and regulate air pressure, supporting comfortable and efficient indoor environments.

Water Management: In water management applications, wireless pressure transmitters are employed to monitor water pressure in distribution networks, pump systems, and wastewater treatment plants for effective resource management.

Pharmaceuticals: Wireless pressure transmitters play a crucial role in pharmaceutical manufacturing processes by monitoring pressure in tanks, reactors, and filtration systems to maintain quality and compliance.

Aerospace and Aviation: In the aerospace and aviation industries, wireless pressure transmitters are used in aircraft systems to monitor cabin pressure, hydraulic systems, and fuel tanks, ensuring safe and efficient flight operations.

Medical Equipment: Wireless pressure transmitters are integrated into medical devices such as infusion pumps, dialysis machines, and patient monitoring systems to deliver accurate pressure measurements for diagnostic and treatment purposes.

These are just a few examples of the wide range of applications where wireless pressure transmitters can be used to enhance monitoring, control, and safety in various industries.

Downloads

SRSACD-Z3 – Pressure Transmitter Specifications

Drawings

Only logged in customers who have purchased this product may leave a review.

A wireless pressure transmitter is a sophisticated device utilized in various industries for measuring, monitoring, and transmitting pressure readings wirelessly. It consists of several components working together seamlessly to provide accurate and reliable pressure data in real time.

A wireless pressure transmitter is a sophisticated device utilized in various industries for measuring, monitoring, and transmitting pressure readings wirelessly. It consists of several components working together seamlessly to provide accurate and reliable pressure data in real time.

Reviews

There are no reviews yet.