Description

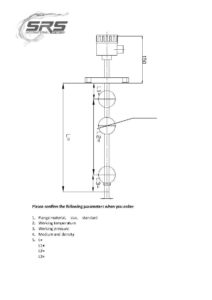

Floating level transmitters are a type of level sensor used to detect the level of substance within a tank. The unit uses a magnetically activated switch to trigger operation. The body of the transmitter is commonly made from strong materials such as stainless steel or plastic. It can be used in water, oil, and other liquid environments, making it a versatile tool in the industry.

The working principle of a floating-level transmitter is simple. The float is designed to float on the surface of the liquid, and as the level of the liquid rises or falls, the float will follow. Inside the float is a magnetic ring, and when the float rises or falls, the magnetic ring moves up and down within a sealed, non-magnetic tube. Inside this tube are one or more reed switches. When the magnetic ring comes into proximity with a reed switch, it activates, sending a signal to the control system indicating the level of the liquid within the tank.

Floating-level transmitters come with various connection ends to suit different applications. These can include threaded connections, flanged connections, and hygienic connections. Threaded connections are typically used for smaller installations where the pressure is not too high. Flanged connections are used for larger installations where the pressure may be high, and a secure connection is required. Hygienic connections are used in industries such as food and beverage or pharmaceutical, where cleanliness and avoiding contamination are paramount.

The floats used in these transmitters can also vary to work with different densities of liquids. For lower-density liquids, larger floats may be used to ensure they stay at the surface. For higher-density liquids, smaller, denser floats may be used. The material of the float can also change depending on the liquid, with stainless steel being a common choice for many applications due to its durability and resistance to corrosion.

In conclusion, floating level transmitters are a reliable and versatile tool for measuring the level of liquids within a tank. Their simple design and the variety of connection ends and floats available make them suitable for a wide range of applications across many industries. Whether you’re working with water, oil, or a specialized liquid in a hygienic environment, there’s likely a floating-level transmitter that’s right for your needs. Remember, it’s important to choose the right transmitter for your specific application to ensure accurate and reliable operation. Always consider the type of liquid, the pressure and temperature conditions, and the required connection type when selecting a floating-level transmitter. With the right choice, these devices can provide years of reliable service.

Please note that this is a general description and the specifications can vary based on the manufacturer and the model of the floating level transmitter. Always refer to the manufacturer’s specifications and guidelines when selecting and installing these devices.

Reviews

There are no reviews yet.