Specifications

Differential Pressure Transmitter Specifications

| |

| Ranges | 0.25 mbar - 7.5 mbar

1.2 mbar - 62.3 mbar

6.2 mbar - .62 bar

24.9 mbar - 2.49 bar

.20 bar - 20.6 bar

|

| Diaphragm Material | 316L SST, Alloy C-276, Alloy 400 |

| Temperature Limits | Ambient: -40 to 185 F

Storage: -50 to 230 F |

| Communication Options | Modbus RTU, HART |

| Output Options | 4-20MA, 0-10vdc |

| LCD | Yes |

Q&A

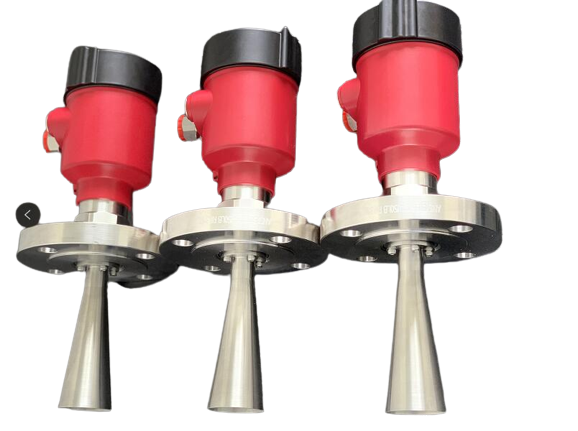

Q: What is a radar-level transmitter?

A: A radar-level transmitter is a type of instrumentation used to measure the level of liquids, solids, or slurries in various industrial processes. It uses radar technology to determine the distance from the transmitter to the surface of the material being measured, providing accurate and reliable level readings.

Q: How does a radar-level transmitter work?

A: Radar-level transmitters emit high-frequency electromagnetic waves toward the material surface. The waves reflect off the surface and return to the sensor. By measuring the time taken for the waves to return, the transmitter calculates the distance to the material surface, which corresponds to the level of the substance being measured.

Q: What are the advantages of radar-level transmitters?

A: Non-contact measurement: Radar level transmitters do not require physical contact with the material being measured, reducing maintenance needs.

– High accuracy: They provide precise and reliable level measurements even in challenging conditions.

– Versatility: Suitable for measuring levels in various substances, including liquids, solids, and slurries.

– Weather resistance: Radar-level transmitters can withstand harsh environmental conditions, making them ideal for outdoor applications.

Q: What are common applications for radar-level transmitters?

A: Radar level transmitters are used in a wide range of industries, including:

– Chemical processing

– Oil and gas

– Water and wastewater treatment

– Food and beverage production

– Pharmaceuticals

– Power generation

Q: How do radar-level transmitters differ from ultrasonic-level transmitters?

A: Radar level transmitters use radar waves, which are less affected by factors such as temperature, pressure, and vapor compared to ultrasonic transmitters. Radar transmitters are also suitable for a wider range of applications and offer higher accuracy in measuring levels of materials with varying dielectric constants. On the other hand, ultrasonic transmitters may be more cost-effective for certain applications and are suitable for shorter-range measurements.

These are just some general questions and information about radar-level transmitters. Let me know if you need more specific questions or details on this topic!

Advantages / Disadvantages

Advantages of a Radar Level Transmitter

Accurate Measurements

Radar level transmitters provide highly accurate measurements, often with millimeter-level precision. This accuracy ensures precise control of inventories, enables efficient process optimization, and helps maintain operational safety.

Reliable in Challenging Environments

Radar level transmitters are unaffected by changes in temperature, pressure, or the presence of vapors, gases, or dust. They can operate reliably in extreme conditions, making them suitable for a wide range of industries, including oil and gas, chemical processing, and wastewater treatment.

Versatility

Radar level transmitters can measure the levels of both liquid and solid materials, making them suitable for a wide variety of applications. They can handle different types of liquids, slurries, solids, or even foam, and are compatible with various tank shapes and obstructions.

Non-Contact Measurement

The non-contact nature of radar-level transmitters eliminates the need for physical contact with the substance being measured. This minimizes the risk of contamination, wear and tear, and damage to the instrument, ensuring long service life and reducing maintenance requirements.

Easy Installation and Setup

Radar-level transmitters are straightforward to install, typically mounted on the top of the tank or vessel. They often come with self-calibration features or automated calibration routines, simplifying the setup process.

Now, let’s move on to the disadvantages:

Disadvantages of a Radar Level Transmitter

Higher Cost

Compared to some other level measurement techniques, radar-level transmitters can be relatively more expensive. Additionally, the advanced radar technology and additional features contribute to the higher upfront costs.

Limited Performance with Certain Substances

While radar-level transmitters are generally versatile, some substances with low dielectric constants or non-reflective surfaces may pose challenges for accurate measurements. Guided wave radar transmitters are often preferred for such applications.

Potential Interference

Radar signals can experience interference from electrical equipment or structures in the vicinity. Such interference may affect the accuracy of measurements and require careful consideration during installation.

Limited Range

Radar level transmitters typically have a limited measurement range, usually up to a few tens of meters. For applications requiring longer ranges, other measurement techniques, like ultrasonic transmitters, may be more suitable.

It’s important to consider these advantages and disadvantages in the context of your specific application requirements and constraints.

Applications

Applications

Oil and Gas

Radar level transmitters are extensively used in the oil and gas industry for measuring the level of crude oil, refined petroleum products, liquefied gases, and other fluids in storage tanks, process vessels, and transportation containers. They ensure precise inventory management, assist in custody transfer operations, and provide critical data for process control.

Chemical Processing

In chemical plants, radar-level transmitters are utilized to measure levels of various chemicals, solvents, acids, and other substances in tanks and reactors. Similarly, they help prevent overflows, optimize batch processes, and ensure the safe handling of hazardous materials.

Water and Wastewater Treatment

Radar level transmitters play a vital role in water treatment facilities for measuring levels in reservoirs, tanks, and wells. Especially, they help monitor water levels, control pumping operations, and manage water distribution networks. Certainly, in wastewater treatment plants, they are used to measure levels in sedimentation tanks, sludge digesters, and other treatment processes.

Food and Beverage

A Radar level transmitter and its applications in the food and beverage industry for measuring levels of liquids such as dairy products, juices, oils, and sauces. Moreover, they provide accurate volume measurements for inventory control, assist in batching and blending processes, and ensure consistent product quality.

Pharmaceuticals

Radar level transmitter is used in pharmaceutical manufacturing facilities to measure levels of liquids, solvents, and chemicals in storage tanks, reactors, and processing vessels. Furthermore, they help maintain proper ingredient quantities, track raw material inventories, and ensure batch consistency.

Power Generation

Radar level transmitters are employed in power plants to measure levels of fuels, such as coal or oil, in storage bunkers, as well as water levels in cooling towers, boilers, and condensers. They provide critical data for efficient fuel management, assist in maintaining optimal boiler water levels, and enhance plant safety.

Mining and Minerals

Radar level transmitters are used in mining operations for measuring levels of ores, slurries, and tailings in storage tanks, hoppers, and processing equipment. They assist in inventory management, control material flow, and ensure efficient mineral extraction processes.

Drawings

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.