Pumps

Pumps are devices that move fluids (liquids or gases), or sometimes slurries, by mechanical action. They can be classified into three major groups according to the method they use to move the fluid. Classifications like direct lift, displacement, and gravity pump.

They operate by some mechanism (typically reciprocating or rotary) and consume energy to perform mechanical work by moving the fluid.

Also, mechanical pumps serve in a wide range of applications such as pumping. SRS Pumps come in different types from Centrifugal, Gear Type, Positive Displacement, Air Diaphragm, Lobe, and Vacuum liquid ring types.

Centrifugal Pumps

Centrifugal pump is a sub-class of dynamic axisymmetric work-absorbing turbomachinery. These pumps are used to transport fluids by the conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow.

The rotational energy typically comes from an engine or electric motor. Fluid enters the pump impeller along or near the rotating axis and is accelerated by the impeller. It then flows radially outward into a diffuser or volute chamber (casing), from where it exits.

In addition, a Centrifugal is commonly used to include water, sewage, petroleum, and petrochemical pumping; a centrifugal fan is commonly used to implement a vacuum cleaner.

Finally, the reverse function of the centrifugal pump is a water turbine converting the potential energy of water pressure into mechanical rotational energy.

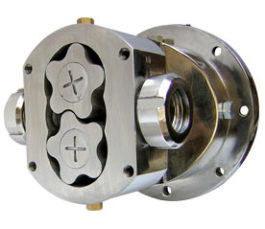

Gear Pumps

First of all, a gear pump uses the meshing of gears to pump fluid by displacement. They are one of the most common types of pumps for hydraulic fluid power applications.

Also, Rotary Gear pumps are widely used in chemical transfer pump installations to pump high-viscosity fluids. There are two main variations, Internal and External.

The external gear pump uses two external spur gears. Internal gear pumps use external and internal spur gears.

They are positive displacement (or fixed displacement), meaning they pump a constant amount of fluid for each revolution. Some gear pumps are designed to function as either a motor or a pump.

Lobe Pumps

They are used in a variety of industries including pulp and paper, chemical, food, beverage, pharmaceutical, and biotechnology.

Also, they are popular in these diverse industries because they offer superb sanitary qualities. It also has high efficiency, reliability, corrosion resistance, and good clean-in-place and steam-in-place (CIP/SIP) characteristics.

In addition, a Rotary can handle solids (e.g., cherries and olives), slurries, pastes, and a variety of liquids. If wetted, they offer self-priming performance. A gentle action minimizes product degradation.

Finally, they also offer continuous and intermittent reversible flows and can operate dry for brief periods.

Flow is relatively independent of changes in process pressure, too, so output is relatively constant and continuous.

Vacuum Pumps

It is a device that removes gas molecules from a sealed volume to leave behind a partial vacuum

SRS Vacuum pumps are Two-stage liquid ring vacuums that are capable of producing a vacuum to 29” Hg. They are available in various materials of construction. Materials like Iron, Bronze, and Stainless steel.

Moreover, pumps are provided with threaded, flanged, and Tri-clamp connections for service liquid, draining, and vacuum relief valves. Optional items include an inlet check valve, vacuum relief valve, flow control, solenoid valve, and vacuum and temperature gauges.

The vacuum pumps can also come as completely packaged units.

Showing all 4 results

-

Centrifugal Pumps

$ 1,195.00 – $ 6,875.00Select options This product has multiple variants. The options may be chosen on the product page -

Vacuum Pumps

$ 1,456.00Select options This product has multiple variants. The options may be chosen on the product page -

Lobe Pumps

$ 3,800.00 – $ 7,600.00Select options This product has multiple variants. The options may be chosen on the product page -

Sale

Gear Pumps

$ 2,125.00 – $ 6,879.00Select options This product has multiple variants. The options may be chosen on the product page