Description

Electromagnetic flow meters, commonly known as mag meters, are a type of flow meter that uses the principles of electromagnetism to measure the flow rate of conductive fluids. These devices are widely used in various industries, including water and wastewater treatment, chemical processing, food and beverage, and pharmaceuticals, due to their accuracy, reliability, and versatility. Here, we’ll explore the principles, construction, operation, advantages, disadvantages, and applications of electromagnetic flow meters in detail.

Principles of Operation

The fundamental principle behind electromagnetic flow meters is Faraday’s Law of Electromagnetic Induction. According to this law, when a conductive fluid flows through a magnetic field, it generates a voltage proportional to the flow velocity. The generated voltage is then measured and used to determine the flow rate of the fluid.

In an electromagnetic flow meter, a pair of coils generates a magnetic field perpendicular to the direction of fluid flow. As the conductive fluid passes through this magnetic field, electrodes positioned orthogonally to the magnetic field and fluid flow detect the induced voltage. This voltage is directly proportional to the flow velocity of the fluid.

Construction

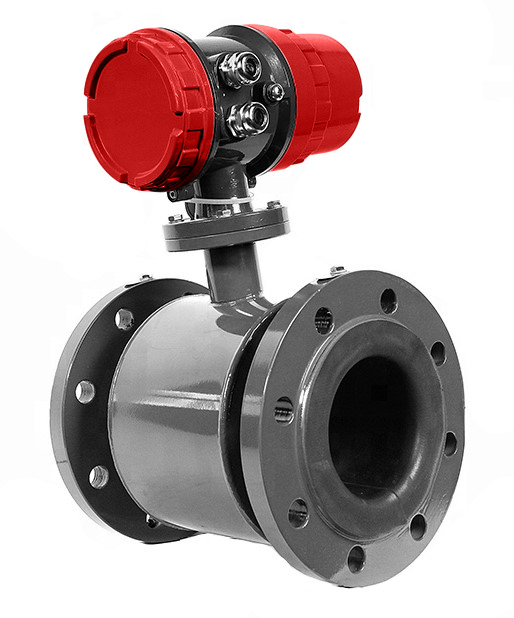

An electromagnetic flow meter typically consists of the following components:

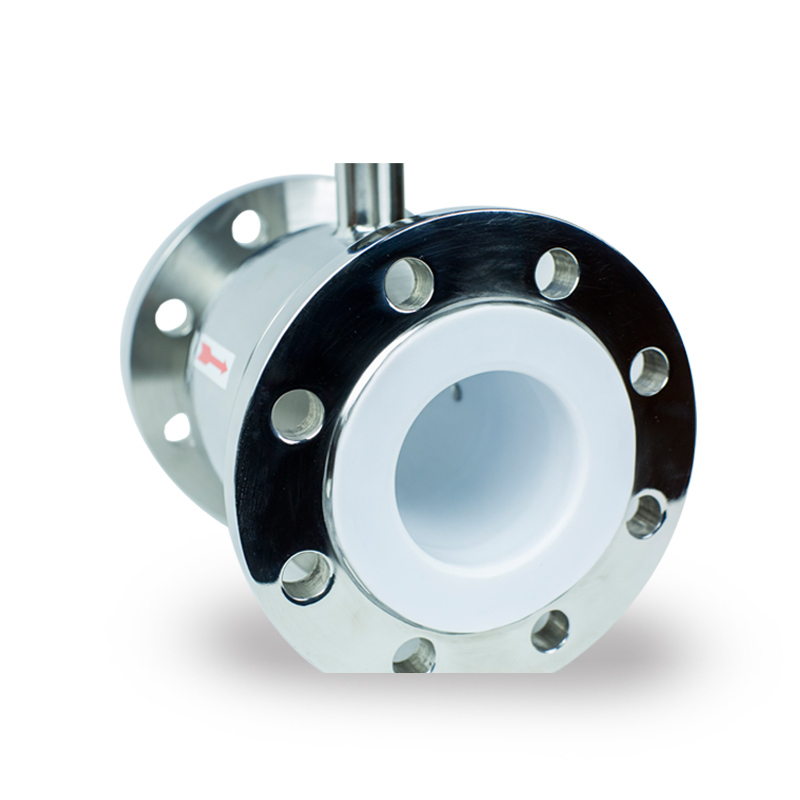

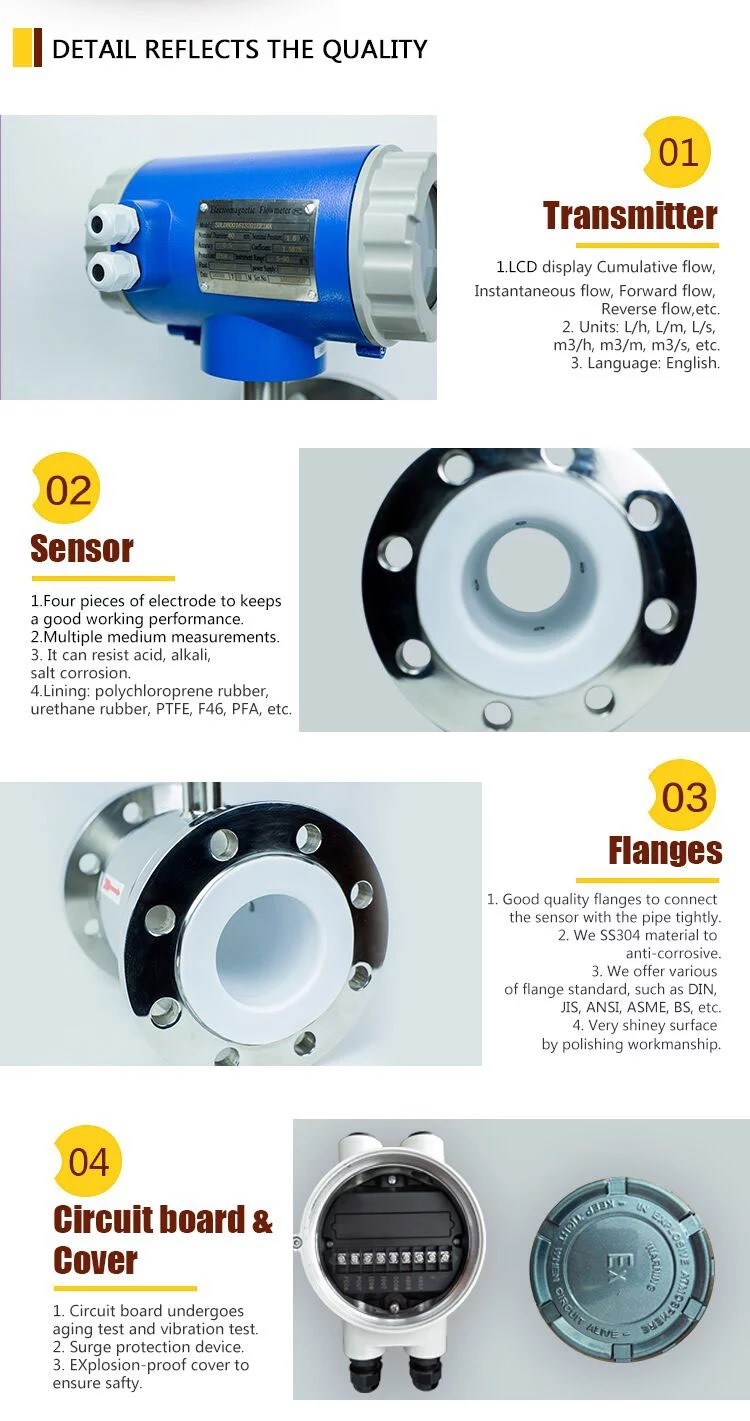

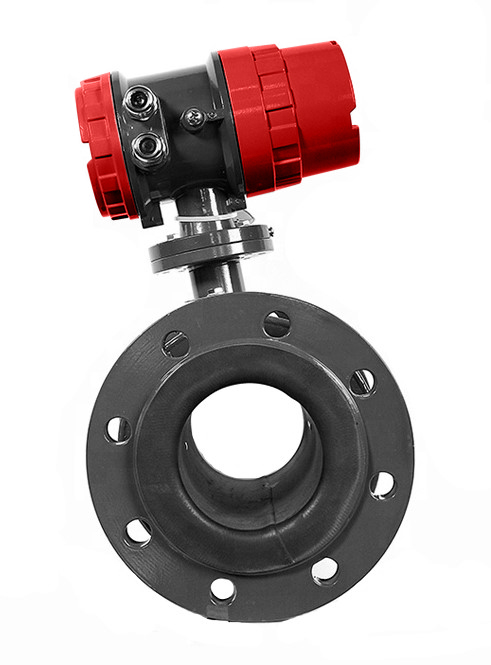

Flow Tube

The flow tube is the part of the meter through which the fluid flows. It is usually made from non-magnetic and non-conductive materials such as stainless steel, PVC, or lined with materials like PTFE to prevent corrosion and ensure compatibility with different types of fluids. The inside surface of the flow tube must be smooth to minimize friction and prevent the buildup of deposits.

Electromagnetic Coils

These coils are responsible for generating the magnetic field. They are typically mounted around or integrated into the flow tube. When an electric current passes through the coils, it creates a magnetic field that interacts with the flowing fluid.

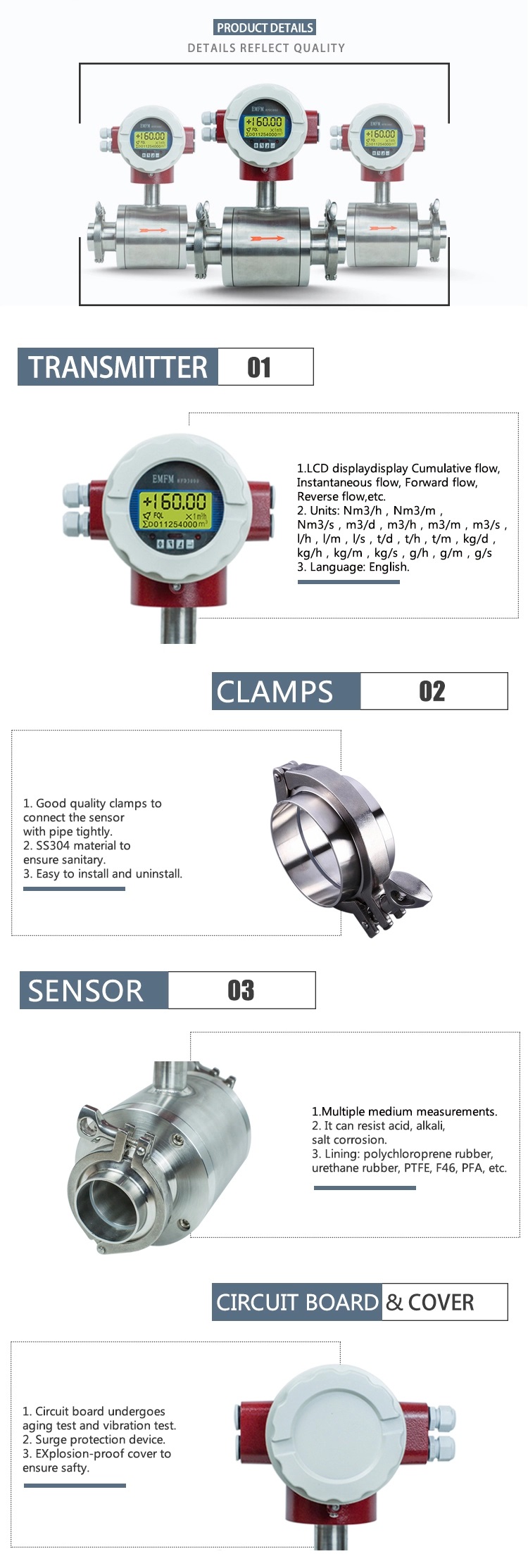

Electrodes

Electrodes are placed at opposite points inside the flow tube to detect the voltage induced by the moving conductive fluid. The material of the electrodes is chosen based on the chemical properties of the fluid to prevent corrosion and ensure long-term reliability.

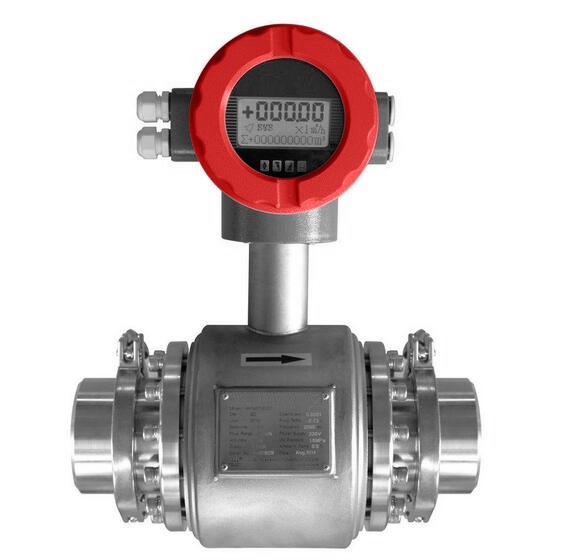

Converter/Transmitter

The converter or transmitter processes the voltage signal detected by the electrodes. It amplifies and converts this signal into a readable flow rate, typically displayed on an LCD screen. The transmitter also allows for data communication with control systems and other monitoring devices, providing outputs such as 4-20 mA signals, pulse outputs, or digital communication protocols like HART or Modbus.

Operation

When the electromagnetic flow meter is in operation, the following steps occur:

Magnetic Field Generation: The electromagnetic coils generate a magnetic field that penetrates the flow tube and the fluid within it.

Fluid Flow: As the conductive fluid flows through the magnetic field, it induces a voltage.

Voltage Detection: The electrodes positioned inside the flow tube detect this induced voltage.

Signal Processing: The detected voltage is sent to the converter, which processes the signal to determine the fluid’s flow rate.

Output and Display: The flow rate is then displayed on the meter’s display and can also be transmitted to external systems for monitoring and control.

Specifications

Electromagnetic Flow Meter Specifications

| Application | Velocity Range (FT/S) | Velocity Range (M/S) |

| Normal Service | 0-39 | 0-12 |

| Preferred Service | 2-20 | 0.6-6.2 |

| Abrasive Slurries | 3-11 | 0.9-6.5 |

| Non-Abrasive Slurries | 5-15 | 1.5-4.6 |

Q&A

A Q&A Electromagnetic Flow Meter which stands for “question and answers for Electromagnetic Flow Meter,” is a format commonly used to facilitate communication and exchange of information. In a Q&A Electromagnetic Flow Meter, one person asks a question, and another person or group provides an answer or response to that question. This format is widely used in various contexts, such as interviews, discussions, presentations, or online forums. It allows for a structured and organized way of addressing inquiries and obtaining relevant information. Is there anything specific you would like to know about Q&A Electromagnetic Flow Meter?

Q: What is an electromagnetic flow meter?

A: An electromagnetic flow meter, also known as a mag meter, is a type of flow meter that uses Faraday’s law of electromagnetic induction. This is to measure the velocity of conductive fluids, such as water or wastewater.

Q: How does an electromagnetic flow meter work?

A: An electromagnetic flow meter works by using a magnetic field to induce an electric voltage in a conductive fluid as it flows through a pipe. The voltage generated is proportional to the velocity of the fluid, which can then be used to calculate the flow rate.

Q: What are the advantages of using an electromagnetic flow meter?

A: Some advantages of using an electromagnetic flow meter include:

-

- High accuracy and repeatability

-

- No moving parts, which reduces maintenance requirements and increases reliability

-

- Can measure flow rates of conductive fluids regardless of their viscosity or density

-

- Can handle high flow rates and can be used in large pipe sizes

-

- Can measure bidirectional flow

Q: What are some common applications for electromagnetic flow meters?

A: Electromagnetic flow meters are commonly used in the water and wastewater industry for measuring flow rates in pipes and open channels. They are also used in the chemical, food and beverage, and pharmaceutical industries for measuring the flow of conductive liquids.

Q: What are some potential limitations or drawbacks of using an electromagnetic flow meter?

A: Some potential limitations of using an electromagnetic flow meter include:

-

- Can only measure the flow rate of conductive fluids

-

- Requires a conductive fluid with a minimum level of conductivity for accurate readings

-

- Can be affected by electromagnetic interference, which can lead to inaccurate readings

-

- Can be more expensive than other types of flow meters, such as ultrasonic or turbine flow meters, depending on the application

Q: Can electromagnetic flow meters be used for hazardous fluids?

A: Yes, electromagnetic flow meters can be used for hazardous fluids as long as the materials of construction are selected to be compatible with the specific fluid and the operating conditions. For example, if the fluid is corrosive, the flow meter should be constructed of a material that is resistant to corrosion.

Q: How are electromagnetic flow meters installed?

A: Electromagnetic flow meters are typically installed in a horizontal or vertical orientation, depending on the application. The flow meter is mounted in the pipe or channel, and the electrodes are inserted through the wall of the pipe or channel and positioned to be in contact with the flowing fluid. The electrodes are then connected to the transmitter, which converts the signal into a flow rate reading.

Q: How accurate are electromagnetic flow meters?

A: Electromagnetic flow meters are known for their high accuracy and repeatability, with typical accuracy levels of ±0.5% to ±1% of the flow rate. However, the accuracy can be affected by several factors, including the fluid properties. Also, the installation location, and the quality of the signal conditioning electronics.

Q: How do electromagnetic flow meters compare to other types of flow meters?

A: Electromagnetic flow meters are often compared to other types of flow meters. Various Types such as ultrasonic, turbine, and positive displacement flow meters. Each type of flow meter has its strengths and weaknesses, and the choice of Electromagnetic flow meter depends on the specific application requirements. In general, electromagnetic flow meters are preferred for applications where high accuracy, and reliability. Also, low maintenance is important, and where the fluid is conductive.

Q: How do Q&A Electromagnetic Flow Meters handle changes in fluid density or viscosity?

A: Electromagnetic flow meters are not affected by changes in fluid density or viscosity, as long as the fluid remains conductive. This is because the meter measures the velocity of the conductive fluid, which is not affected by changes in its physical properties.

Q: Can electromagnetic flow meters be used for both liquids and gases?

A: Electromagnetic flow meters are designed to measure the flow of liquids, not gases. This is because gases are not conductive, so they do not generate the electrical signal needed for the meter to work.

Q: Can electromagnetic flow meters be used in applications with high turbulence or flow disturbances?

A: Electromagnetic flow meters can be used in applications with high turbulence or flow disturbances. As a result, the installation location and configuration of the meter must be carefully chosen. This is to minimize the impact of these factors on the accuracy of the meter.

Q: How do electromagnetic flow meters handle air or gas bubbles in the fluid?

A: Electromagnetic flow meters can be affected by air or gas bubbles in the fluid. They can disrupt the conductive properties of the fluid and cause errors in the flow measurement. To address this, some meters have built-in algorithms to detect and correct the presence of bubbles. Also, others may require additional hardware, such as a bubble eliminator or a degassing unit.

Electromagnetic Flow Meter

Advantages / Disadvantages

Benefits of electromagnetic flow meters include:

High accuracy: Electromagnetic flow meters offer excellent measurement accuracy, typically within ±0.5 to 1% of the flow rate. This enables precise flow monitoring and control.

Wide range of fluid compatibility: These flow meters can handle a variety of conductive fluids, including corrosive, abrasive, and viscous liquids. They are suitable for applications across different industries.

Minimal pressure loss: Electromagnetic flow meters have a negligible pressure drop due to their full-bore design, ensuring energy efficiency and reduced operating costs.

Low maintenance: Unlike mechanical flow meters, electromagnetic flow meters have no moving parts. This reduces the need for maintenance and minimizes the risk of mechanical wear and failure.

Versatile installation options: These flow meters can be installed in various orientations. Such as horizontal and vertical pipelines, making them adaptable to different installation requirements.

Applications

Industries Served for Electromagnetic Flow Meter

Overall, electromagnetic flow meters are widely used in industries such as water and wastewater management, chemical processing, pharmaceuticals, food and beverage, and many others. Their accuracy, reliability, and ability to handle a broad range of flow rates and fluid conditions make them a popular choice for flow measurement in various applications.

Electromagnetic flow meters are commonly used in a variety of applications across industries.

Some key applications include:

Water and wastewater treatment: Electromagnetic flow meters are frequently used for measuring the flow rate of water and wastewater in treatment plants. They are highly accurate and reliable, even with fluids containing suspended solids and chemicals.

Chemical and petrochemical industry: In chemical and petrochemical processes, precise flow measurement is crucial for optimizing production and ensuring the safety of operations. Electromagnetic flow meters are widely used for measuring corrosive and hazardous fluids in this industry.

Food and beverage industry: Electromagnetic flow meters find applications in the food and beverage industry for measuring the flow rate of liquids such as milk, fruit juices, and syrups. They are hygienic, have no moving parts, and can handle fluids with solid particulates.

Pharmaceutical industry: Flow metering is critical in pharmaceutical manufacturing to ensure accurate dosing and maintain product quality. Electromagnetic flow meters are commonly used for measuring the flow rate of various liquids, including solvents, acids, and bases.

Drawings

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.