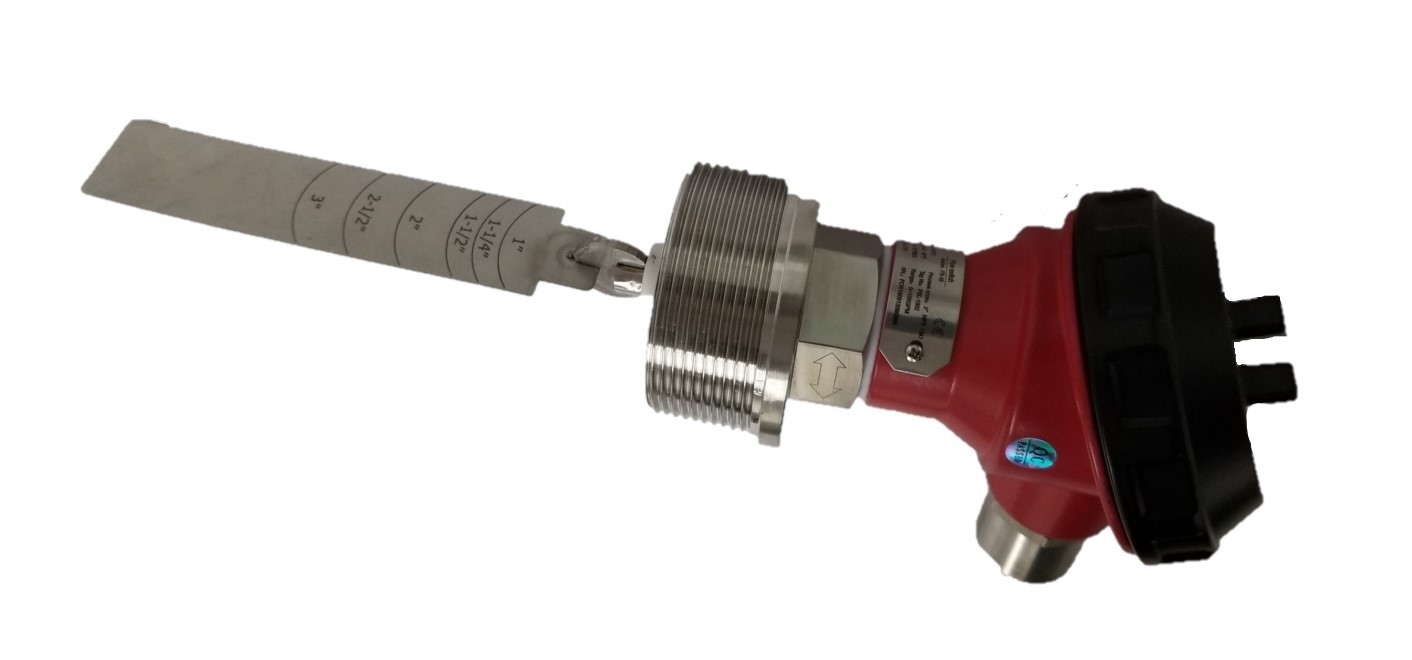

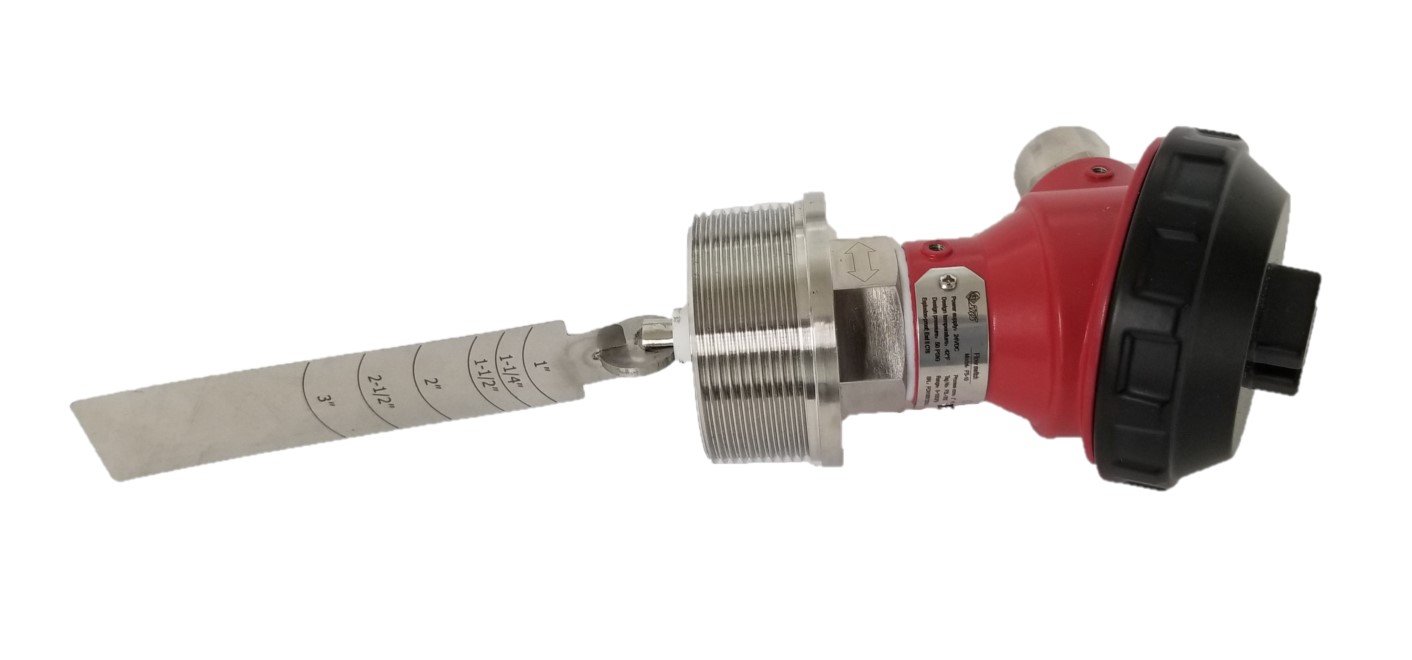

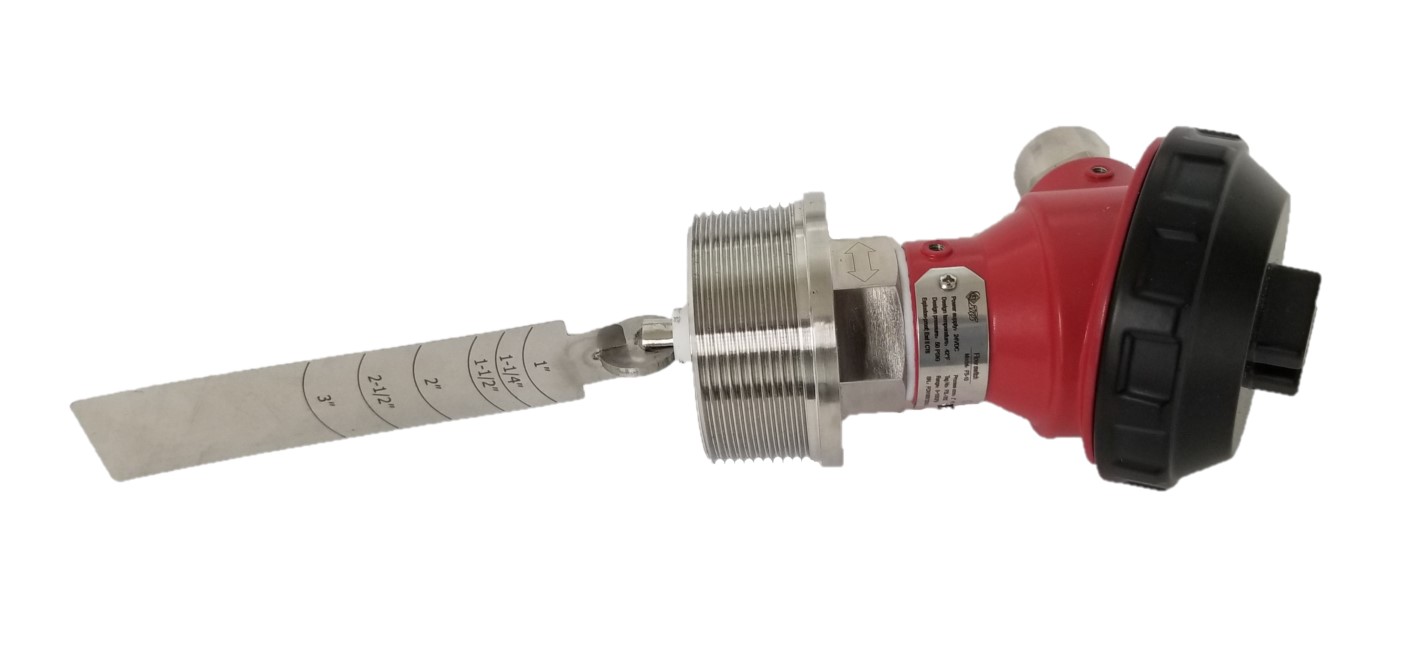

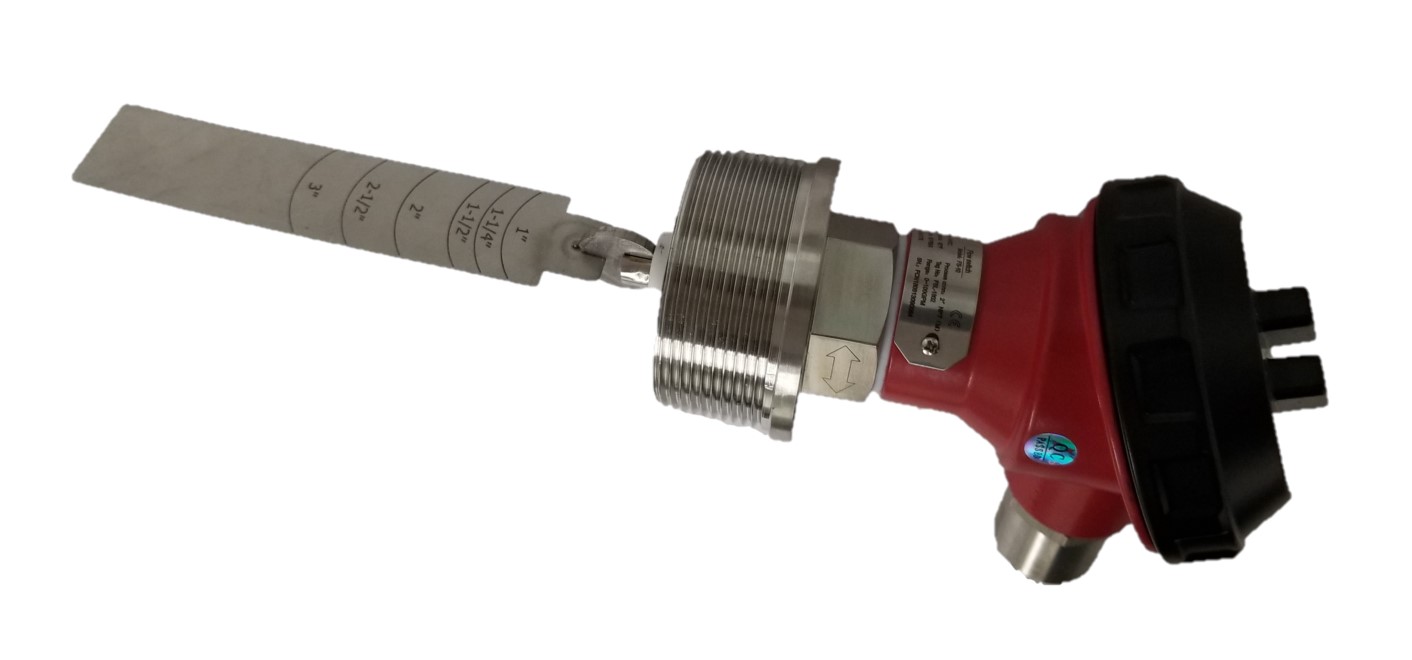

Flow Switch

$ 225.00 – $ 295.00

A flow switch is a crucial device used in fluid systems to monitor flow rates and trigger specific actions based on predefined thresholds. It is equipped with a sensing mechanism that detects the movement of liquids or gases passing through pipelines, ducts, or other systems. When the flow rate reaches a specified level, the flow switch generates a signal or activates a control mechanism to either enable or stop the flow, providing an essential safety measure and ensuring optimal system performance.

These versatile devices find application in various industries including HVAC, water treatment, chemical processing, and manufacturing. They serve purposes such as pump protection, leak detection, flow control, and system safety. The adjustable setpoints in flow switches allow for customization to suit specific flow rate requirements and system configurations. With different types available such as paddle-type, thermal dispersion, and magnetic flow switches, they offer a reliable solution for flow monitoring and control in fluid systems.

Description

In fluid systems, users employ a flow switch to monitor the flow rate of liquids or gases and to trigger a response based on the presence or absence of flow. Its design includes providing a signal or initiating a control action when the flow rate reaches a certain threshold. Furthermore, this offers a vital means of ensuring system efficiency, safety, and proper operation.

Here is a detailed breakdown of the components and operation of a flow switch:

Sensing Mechanism: The core component of a flow switch is the sensing mechanism, which detects the movement of the fluid passing through a pipeline or duct. Common sensing methods include paddle-type switches. Also, magnetic switches, thermal dispersion switches, and turbine switches, are each suited for different flow rate ranges and fluid types.

Signal Output: When the flow rate reaches a predetermined level, the flow switch triggers a signal output, such as an electrical contact closure, a pneumatic signal, or a digital signal, which can activate alarms, control valves, pumps, or other devices in the system.

Adjustable Setpoint: Many flow switches allow for the adjustment of the setpoint. This allows customization of the flow rate at which the switch activates. This flexibility is vital for tailoring the switch to specific system requirements.

Installation: Flow switches are typically installed in-line within the pipeline or duct. Ensuring this will expose the sensor to the flow of the fluid. Proper installation is crucial for accurate flow monitoring and reliable operation.

Applications: Various industries commonly use flow switches in applications like HVAC, water treatment, chemical processing, oil and gas, and manufacturing. Industries utilize them to monitor pump protection and indicate fluid flow in cooling systems. Also, it detects leaks, controls flow in pipelines, and ensures system safety.

Types of a Flow Switch

Paddle Type: Utilizes a pivoting paddle that moves with the flow, triggering a switch when the flow rate is sufficient to move the paddle.

Thermal Dispersion: Uses temperature sensors to detect changes in the thermal properties of the fluid as it flows.

Magnetic: Operates based on changes in the magnetic field of the fluid, activating a switch when the flow rate surpasses the setpoint.

In summary, a flow switch is a critical component in fluid systems. It provides real-time monitoring of flow rates and enables automated responses to maintain system efficiency and safety. Its versatility and adaptability make it an essential tool in a wide range of applications. Its versatility ensures smooth operation and protection of equipment from flow-related issues.

Specifications

SPECIFICATIONS:

Housing Material: Aluminum Alloy, NEMA 4 (IP65)

Operation Temp.: -30 to 150°C (30 to 300°F)

Paddle Material: SUS304 (Similar to 304 SS)

Operation Pressure: 355 psig

Pressure Drop Allowance: 3 psig

Set Point Tolerance: ±25%

Repeatability Tolerance: ±5%

Contact Capacity: 30 Watts/200 Vdc, SPDT

Max Viscosity: 200 SSU or 43 centistokes

Q&A

A Q&A Flow Switch, which stands for “question and answer for a Flow Switch,” is a format commonly used to facilitate communication and exchange of information. In a Q&A Flow Switch, one person asks a question, and another person or group provides an answer or response to that question. This format is widely used in various contexts, such as interviews, discussions, presentations, or online forums. It allows for a structured and organized way of addressing inquiries and obtaining relevant information. Is there anything specific you would like to know about Q&A Flow Switch?

Q: What is a Q&A Flow Switch?

A: A flow switch is a device that is used to detect the presence or absence of flow in a fluid system. It typically consists of a sensor and a switch and is designed to activate or deactivate a circuit. This activation and deactivation is based on whether or not flow is present.

Q: What are the different types of flow switches?

A: There are several types of flow switches, including paddle flow switches, thermal flow switches, and magnetic flow switches. Paddle flow switches use a paddle or vane to detect the flow of fluid, while thermal flow switches use a heated element to detect changes in flow velocity. Magnetic flow switches use a magnetic field to detect the presence of fluid flow.

Q: How are flow switches used in industrial applications?

A: Flow switches are commonly used in industrial applications to monitor flow in pipes, hoses, and other fluid systems. They may be used to trigger alarms, activate pumps or valves, or shut down equipment in the event of a flow interruption. For example, a Q&A Flow Switch may be used to detect low flow rates in a cooling system or to shut down a pump. This will occur in the event of a leak in a chemical processing plant.

Q: How are flow switches installed and maintained?

A: Flow switches are typically installed in the fluid system using a T-fitting or other appropriate connection. It is important to ensure that the flow switch is properly oriented and positioned within the flow stream to ensure accurate and reliable operation. Maintenance requirements for flow switches will vary depending on the type of switch and the application. In general, it is important to periodically inspect the switch for damage or wear and to clean or replace any components as needed. This ensures reliable operation. It is also important to follow the manufacturer’s guidelines for installation, operation, and maintenance.

Q: What are some factors to consider when selecting a Q&A Flow Switch?

A: When selecting a flow switch, there are several factors to consider. These may include the type of fluid being monitored, the flow rate, the operating temperature, and pressure. In addition, the size of the pipe or tubing, and the required accuracy and sensitivity of the switch. It is important to choose a switch that is appropriate for the specific application to ensure reliable and accurate operation.

Q: Can flow switches be used with different types of fluids?

A: Flow switches can be used with a wide range of fluids, including liquids and gases. However, it is important to choose a switch that is compatible with the specific fluid being monitored. This will ensure accurate and reliable operation. Some flow switches may be designed specifically for use with certain types of fluids. They also have limitations in terms of the types of fluids they can monitor.

Q: Are there any limitations to using flow switches?

A: While flow switches are a useful tool for monitoring fluid flow in a variety of applications, they do have some limitations. For example, they may not be suitable for use with fluids that are highly viscous or contain particulate matter. In that case, they can interfere with the operation of the switch. In addition, flow switches may be less accurate than other types of flow measurement devices. Other devices such as flow meters, may have a limited range of sensitivity. It is important to carefully consider the specific requirements of the application. Equally important is to choose the appropriate device for the task at hand.

Q: Can flow switches be integrated with other control systems?

A: Yes, flow switches can be integrated with other control systems, such as programmable logic controllers (PLCs) or building automation systems. This allows for greater flexibility and control over the monitoring and operation of fluid systems. It will also help to improve efficiency and reduce downtime. However, it is important to ensure that the flow switch is compatible with the specific control system being used. Also, it will require appropriate connections and protocols to be in place.

Buy

Flow Switches

Advantages / Disadvantages

Advantages of Flow Switches

Flow Monitoring

Flow switches allow continuous monitoring of fluid flow, ensuring that flow rates remain within desired parameters. This helps maintain system efficiency and prevents potential issues caused by inadequate or excessive flow.

Automated Control

Flow switches can be integrated into control circuits, enabling automated control mechanisms. They can trigger the operation of pumps, fans, alarms, or other devices based on flow conditions, reducing the need for manual monitoring and intervention.

Safety Measures

Flow switches play a crucial role in ensuring the safety of systems and processes. They can detect abnormal flow conditions such as low flow, no flow, or excessive flow, triggering alarms, or initiating shutdown procedures to prevent equipment damage or hazards.

Process Optimization

By monitoring flow rates, flow switches help optimize processes in various industries. Maintaining accurate flow control ensures consistent product quality, avoids variations, and enhances overall efficiency.

Reliability

Flow switches are generally reliable and durable devices. They are designed to withstand harsh environmental conditions and have a long operational life, making them suitable for demanding industrial applications.

Easy Installation

Flow switches are typically easy to install and integrate into existing systems. They often come with simple mounting mechanisms and provide flexible options for connection to the control circuit.

Disadvantages of Flow Switches

Maintenance

Although flow switches generally require minimal maintenance, periodic inspection, and cleaning may be necessary to ensure optimal performance. Accumulation of debris or sediment can hinder the proper functioning of the flow-sensing element and affect accuracy.

Sensitivity to Fluid Properties

Some flow switches may be sensitive to specific fluid properties, such as viscosity or chemical composition. It’s important to select the appropriate flow switch model suitable for the fluid being monitored to ensure accurate measurements.

Cost

Depending on the specific requirements and industry, flow switches can vary in cost. They may have a higher upfront cost compared to less sophisticated flow monitoring devices. However, their functionality and long-term reliability often outweigh the initial investment.

Limited Flow Range

Different flow switches have specific flow rate ranges within which they can accurately measure and respond to flow changes. If the flow exceeds or falls below this range, the flow switch may not provide reliable readings or fail to trigger the required actions.

Size and Space Requirements

Some flow switches, especially those designed for high flow rates, can be relatively large. This may pose challenges when space is limited or when retrofitting existing systems.

Overall, the advantages of flow switches, such as flow monitoring, automated control, safety measures, and process optimization. This makes them valuable devices across various industries. While they may have some limitations like maintenance requirements or sensitivity to specific fluid properties. Additionally, these factors can often be addressed with proper selection, installation, and regular maintenance practices.

Applications

Flow switches are devices that monitor the flow of fluids (liquid or gas) in pipelines and trigger an action based on the flow rate, presence, or absence of flow. Here are some common applications in which flow switches are used:

HVAC Systems: Flow switches are employed in heating, ventilation, and air conditioning systems to monitor the flow of water, refrigerants, or air in ducts, pipes, and coils. They help ensure proper circulation and efficient operation of HVAC equipment.

Cooling Systems: Flow switches are used in cooling systems, such as chiller plants, cooling towers, and air handling units, to detect the flow of coolant or water. They can trigger alarms or shut down equipment in case of inadequate flow, preventing overheating and equipment damage.

Fire Sprinkler Systems: Flow switches are integrated into fire protection systems to detect the flow of water in fire sprinkler pipes. They can activate alarms, notification systems, or fire suppression equipment when water flow is detected, indicating a potential fire incident.

Industrial Process Control: Flow switches are utilized in various industrial processes to monitor the flow of liquids or gases. They can be used to control pumps, compressors, valves, and other equipment based on flow conditions, ensuring smooth operation and process efficiency.

Water Treatment Plants: Flow switches play a crucial role in water treatment facilities to monitor the flow of water for various purification and filtration processes. They can detect flow disruptions, leaks, or abnormal flow rates, enabling prompt intervention and system maintenance.

Chemical Processing: Flow switches are used in chemical processing plants to monitor the flow of chemicals through pipelines. They help regulate chemical dosing, ensure proper mixing, and provide safety by triggering alarms in case of flow deviations.

Oil and Gas Industry: Flow switches are employed in oil and gas pipelines, refineries, and production facilities to monitor the flow of oil, gas, or other fluids. They are critical for ensuring operational safety, leak detection, and flow control in high-risk environments.

Monitoring Equipment: Flow switches can also be integrated into equipment such as medical devices, laboratory instruments, and research equipment to monitor and control the flow of fluids for precise measurements, safety, and process control.

Overall, flow switches are versatile devices used in a wide range of industries and applications to ensure proper flow monitoring, system protection, and efficient operation of fluid systems.

Drawings

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.