Description

The Vortex Flow Meter is a vital instrument used in fluid measurement and control applications across various industries. It is a highly accurate and reliable device that measures the flow rate of liquids, gases, and steam through a pipe. In this article, we will delve into the working principle, components, and applications of the Vortex Flow Meter, providing a comprehensive understanding of its functionality.

Working Principle

The working principle of the Vortex Flow Meter is based on the von Kármán effect, which states that when a fluid flow passes through a bluff body (shaped like a triangular or rectangular prism) inserted into the pipe, it generates alternating vortices on both sides of the obstacle. These vortices create pressure fluctuations known as vortex shedding. The frequency of these pressure fluctuations is directly proportional to the velocity of the fluid flow, allowing for the measurement of flow rate.

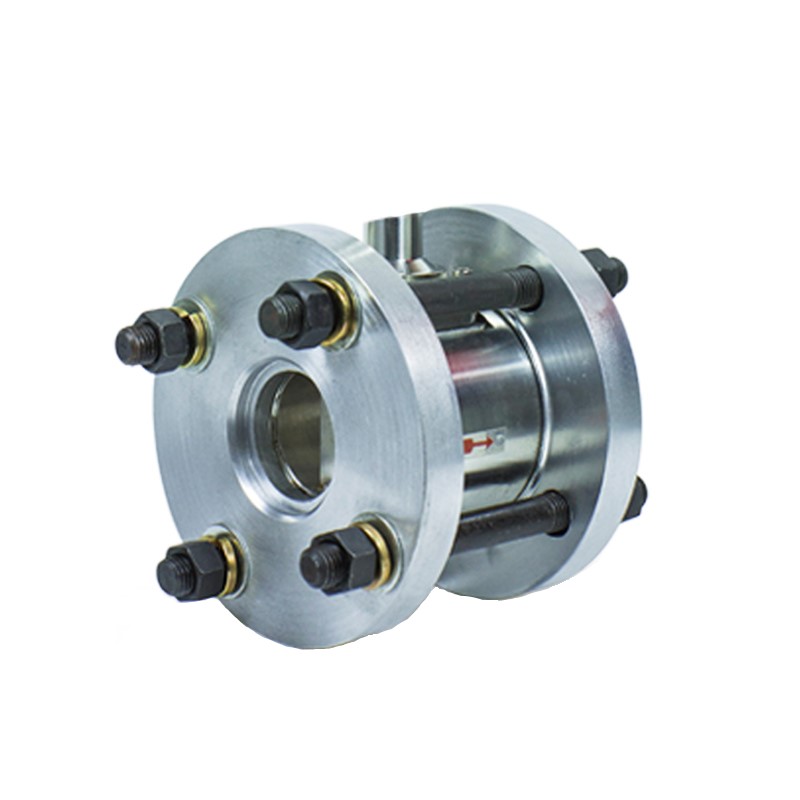

The Vortex Flow Meter consists of several key components. The primary element is the bluff body, which disrupts the flow and generates the alternating vortices. The bluff body can have different shapes and sizes based on specific application requirements. It is typically made of stainless steel or other durable materials to withstand the fluid conditions.

Science

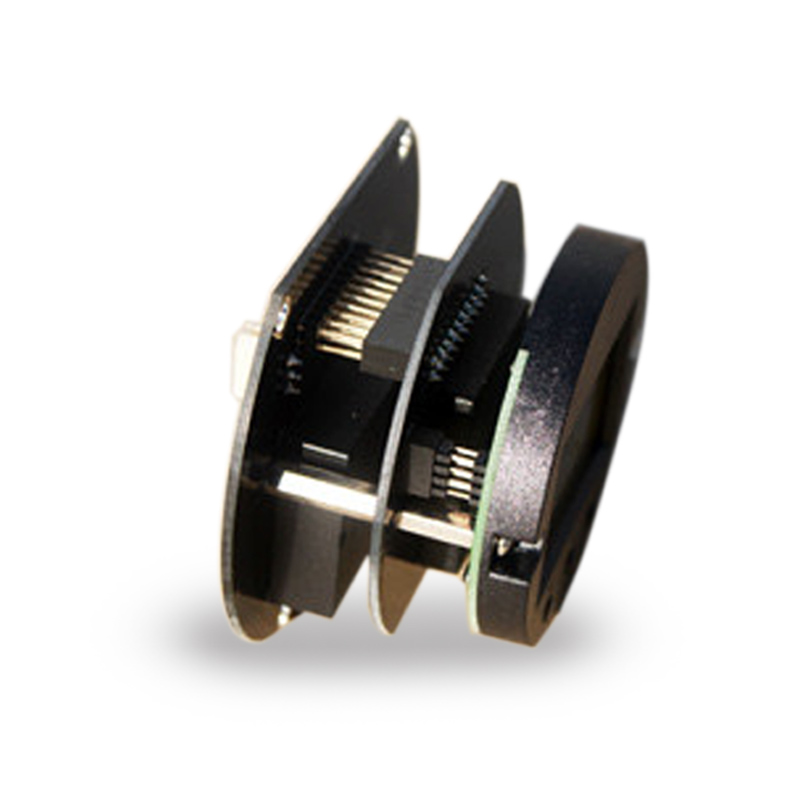

Attached to the bluff body is a sensor, often a piezoelectric crystal or pressure sensor. This sensor picks up the pressure fluctuations caused by the vortex shedding and converts them into electrical signals. These signals are then processed by a transducer, which amplifies and conditions the signals to make them suitable for further analysis.

The Vortex Flow Meter also includes a signal converter or flow transmitter that converts the electrical signals into a standardized form such as a 4-20 mA current loop or a digital output. This standardized signal is then used by a flow controller or data acquisition system for flow measurement and control purposes.

One of the advantages of using a Vortex Flow Meter is its high accuracy and repeatability. It offers a wide turndown ratio, allowing it to accurately measure low and high flow rates with the same level of precision. Additionally, it has no moving parts, reducing the need for maintenance and minimizing the risk of mechanical failure.

Industries Used

The Vortex Flow Meter finds applications in various industries, including oil and gas, chemical processing, pharmaceuticals, water treatment, and HVAC (heating, ventilation, and air conditioning) systems. Its ability to handle a wide range of fluids, such as liquids, gases, and steam, makes it a versatile device for flow measurement in different environments.

Oil and Gas

In the oil and gas industry, the Vortex Flow Meter is used to measure the flow rate of crude oil, natural gas, and petroleum products in pipelines. It helps in monitoring the consumption and distribution of these valuable resources, ensuring accurate billing and facilitating efficient operations.

Chemical Processing

In chemical processing plants, the Vortex Flow Meter aids in measuring the flow rates of various chemicals and solvents. This information is crucial for controlling the production process, maintaining product quality, and optimizing resource utilization.

Pharmaceutical

The pharmaceutical industry utilizes the Vortex Flow Meter for measuring the flow of fluids during drug manufacturing. It ensures accurate dosing and precise control of ingredients for producing high-quality medications.

Water Treatment

The Vortex Flow Meter also plays a crucial role in water treatment facilities, where it helps in measuring the flow rate of water for efficient distribution and consumption assessment. It aids in detecting leaks, optimizing water usage, and facilitating the maintenance of water supply networks.

HVAC

In HVAC systems, the Vortex Flow Meter is used to measure the flow rate of air and other gases, contributing to effective climate control in buildings and ensuring optimal energy usage.

In conclusion, the Vortex Flow Meter is a sophisticated instrument that utilizes the principle of vortex shedding to accurately measure the flow rate of fluids. Its high accuracy, wide turndown ratio, and versatility make it a valuable tool in various industries. By providing reliable flow data, the Vortex Flow Meter enables precise control, efficient resource utilization, and optimal performance in fluid measurement and control applications.

Advantages and Disadvantages

Vortex flow meters are commonly used to measure the flow rate of liquids, gases, and steam. These meters have several advantages and disadvantages. Let’s start with the advantages:

Advantages

Wide Range of Applications

Vortex flow meters can be used in various industries, including oil and gas, chemical, water and wastewater, and food and beverage, making them versatile instruments for flow measurement.

Low-Pressure Drop

Vortex flow meters have a minimal pressure drop, meaning they don’t significantly restrict the flow of the fluid being measured. Additionally, this is beneficial in systems where pressure preservation is critical.

No Moving Parts

One of the significant advantages of vortex flow meters is that they don’t have any moving parts. This makes them more reliable, reduces maintenance requirements, and decreases the risk of mechanical failure.

Accurate and Repeatable Measurements

Vortex flow meters can provide accurate and repeatable measurements, especially when calibrated properly. They are known for their high levels of measurement stability.

Wide Turndown Ratio

Vortex flow meters have a wide turndown ratio, which means they can measure a broad range of flow rates accurately. This flexibility allows for enhanced performance in varying flow conditions.

Disadvantages

Sensitivity to Installation Conditions

Vortex flow meters can be sensitive to the conditions in which they are installed. Also, factors such as pipe vibrations, swirls, and obstructions can affect their accuracy. Finally, proper installation, accounting for these factors, is crucial.

Limited Accuracy at Low Flow Rates

Vortex flow meters may not provide accurate readings at very low flow rates. Additionally, the presence of turbulence and irregular flow patterns at low flow rates can compromise their precision in these conditions.

Susceptibility to Temperature and Density Changes

Changes in temperature and fluid density can impact the accuracy of vortex flow meters. It is important to consider compensating for these variations when using these meters.

Cost

Vortex flow meters can be more expensive than some other types of flow meters, such as turbine or positive displacement meters. Moreover, the initial investment cost may be higher, especially for larger pipe sizes or specialized applications.

Remember, these points are general advantages and disadvantages of vortex flow meters. It is always recommended to consult with a flow measurement specialist or manufacturer for specific application requirements and considerations.

Other Specifications

The piezoelectric element encapsulated in the detection probe body generates an alternating charge signal. The signal is the same frequency as the vortex, under the action of alternating stress.

Furthermore, the signal is sent to the intelligent flow totalizer to be processed after being amplified by the pre-amplifier. In Addition, it will realize displaying instantaneous flow and cumulative flow of fluid, communicating and controlling flow data and the microcomputer system.

In conclusion, a certain range of Reynolds number (2×10^4~7×10^6), the relationship among vortex releasing frequency fluid velocity V.

It also has a vortex generator facing flow surface width d can be expressed by the following equation:

Vortex Flow Meter Features

- The unique isolated sensor design allows for replacement without breaking the process seal

- Increase plant availability and reduce potential leak points with a gasket-free meter body with no moving parts

- Eliminate downtime and maintenance costs associated with plugged impulse lines with a non-clog meter body design

- Achieve vibration immunity with a mass-balanced sensor and Adaptive Digital Signal Processing with visual filtering

- A standard internal signal generator included in every meter simplifies electronics verification

- All meters arrive pre-configured and hydrostatically tested, making them ready and easy to install

- Simplify SIS compliance with available dual and quad Vortex