Coriolis Flow Meter and Mass Meters

$ 1,510.00 – $ 67,690.00Price range: $ 1,510.00 through $ 67,690.00

A Coriolis flow meter is a cutting-edge device used for precise measurement of fluid flow and density. It operates based on the Coriolis effect, where the flow of fluid through a vibrating tube creates a change in the tube’s vibration frequency. This change is directly proportional to the mass flow rate of the fluid, allowing for highly accurate measurement of both flow rate and density.

The design of a Coriolis flow meter typically features one or more vibrating tubes through which the fluid passes. As the fluid flows, it affects the vibration of the tubes in a manner that can be precisely measured and analyzed. This results in a highly accurate determination of the mass flow rate and density, which are crucial for various applications in industries such as chemical processing, oil and gas, pharmaceuticals, and food and beverage.

One of the primary advantages of Coriolis flow meters is their ability to provide direct mass flow measurement, eliminating the need for additional pressure or temperature compensation. They are also known for their high accuracy, reliability, and ability to handle a wide range of fluid types, including those with varying viscosities and temperatures.

Additionally, Coriolis flow meters often come equipped with advanced diagnostics and communication capabilities, enabling real-time monitoring and integration with control systems. This makes them an invaluable tool for optimizing processes, ensuring product quality, and enhancing overall operational efficiency in industrial settings.

Description

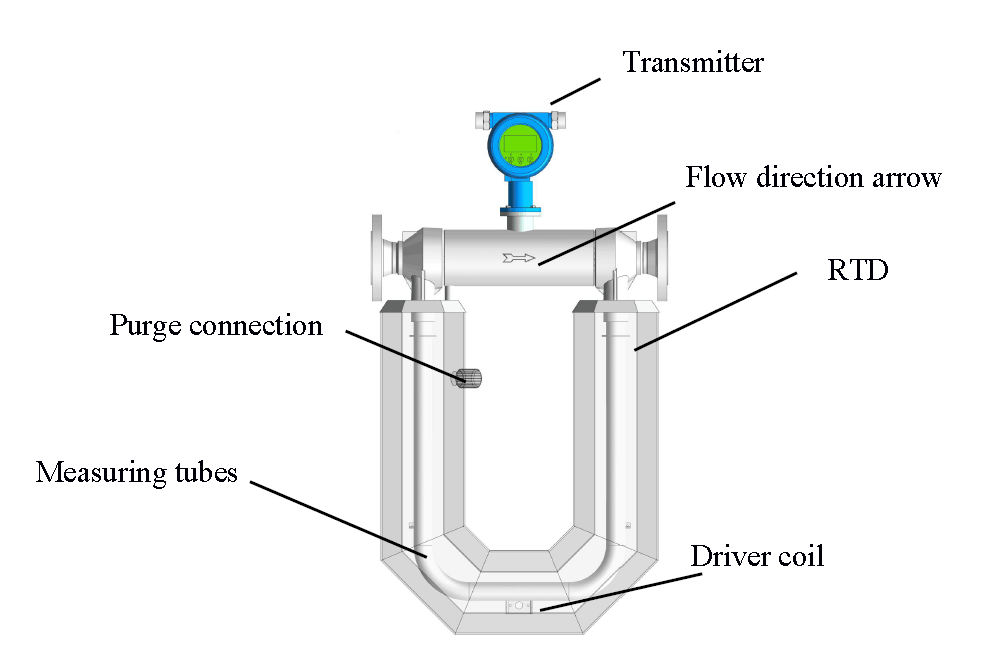

The Coriolis Flow Meter and Mass Meters are instruments used to measure the mass flow rate of a fluid. They operate on the principle of Coriolis force, which is a force that acts on a mass moving in a rotating system. A Coriolis flow meter consists of a U-shaped tube that is oscillated at a specific frequency. When a fluid flows through the tube, it causes a twisting motion in the tube due to the Coriolis force acting on the fluid. This twisting motion is proportional to the mass flow rate of the fluid. Also, it is measured by sensors placed at the inlet and outlet of the tube.

The Coriolis Flow Meter and Mass Meters are instruments used to measure the mass flow rate of a fluid. They operate on the principle of Coriolis force, which is a force that acts on a mass moving in a rotating system. A Coriolis flow meter consists of a U-shaped tube that is oscillated at a specific frequency. When a fluid flows through the tube, it causes a twisting motion in the tube due to the Coriolis force acting on the fluid. This twisting motion is proportional to the mass flow rate of the fluid. Also, it is measured by sensors placed at the inlet and outlet of the tube.

The advantages of Coriolis Flow Meter and Mass Meters include their ability to measure the mass flow rate directly, their high accuracy, and their ability to handle a wide range of fluid types and viscosities. Industries commonly use them, including oil and gas, chemicals, food and beverage, and pharmaceuticals.

Why is the Expensive

However, they are generally more expensive than other types of flow meters, and they may not be suitable for applications where the fluid contains solid particles or where the flow rate is very low. Additionally, they may require periodic calibration to maintain their accuracy. The Mass Flow Meter does not measure the volume per unit time (e.g., cubic meters per second) passing through the device; it measures the mass per unit time (e.g., kilograms per second) flowing through the device.

The Coriolis Flow Meter and Mass Meters can detect the flow of all liquids and gases. The food and chemical industries primarily use this.

Technical Side of Coriolis Flow Meters

Volumetric:

You calculate the volumetric flow rate by dividing the mass flow rate by the fluid density. If the density is constant, then the relationship is simple. If the fluid has varying densities, then the relationship is not simple.

Density:

The density of the fluid may change with temperature, pressure, or composition, for example. Also, the fluid may be a combination of phases such as a fluid with entrained bubbles. The Actual density is due to the dependency of sound velocity on the controlled liquid concentration.

What happens to the Fluid?

Fluid is being pumped through the Coriolis flow meter or mass flow meter. When there is mass flow, the tube twists slightly. The arm through which fluid flows away from the axis of rotation must exert a force on the fluid, to increase its angular momentum, so it bends backward.

Curved Mass Flow Meters:

Engineers design curved tube mass flow meters to lead the fluid through two parallel tubes. The actual frequency of the vibration depends on the size of the mass flow meter. The frequency has a range from 80 to 1000 Hz.

When no fluid is flowing on Coriolis flow meters, the motion of the two tubes is symmetrical, as shown in the left animation.

What happens during mass flow:

- Some twisting of the tubes

- The arm carrying the flow away from the axis of rotation must exert a force on the fluid. You use this to accelerate the flowing mass to match the vibrating speed of the tubes. This occurs at the outside (an increase of absolute angular momentum), so it is lagging behind the overall vibration.

The arm that pushes the fluid back towards the axis of movement must exert a force on the fluid. You use this to decrease the fluid’s absolute angular speed. Also, the inlet arm and the outlet arm vibrate with the same frequency as the overall vibration, but when there is mass flow the two vibrations are out of sync: the inlet arm is behind, and the outlet arm is ahead. The two vibrations are shifted in phase concerning each other. It is the degree of phase shift is a measure of the amount of mass that is flowing through the tubes.

Coriolis Flow Meter and Mass Meters Economics:

These mass flow meters provide short payback periods on applications where measurement accuracy lowers production costs. You can achieve a short payback when you need to take multiple measurements, including density, temperature, and pressure. On the other hand, they may not be competitive when used in simple flow measurement applications. Where volumetric sensors are sufficient and where repeatability is more important than precision. Other types like Turbine, Electromagnetic, and Ultrasonic, and Vortex may be the preferred choice.

Coriolis mass flow meters can detect the flow of all liquids and gases. This type of detection is perfect for the food and chemical industry. The reason is that they are the best choice for an accurate flow meter.

If the Coriolis Flow Meter does not meet your application requirements pls look at another type of flow meter below

Turbine Flow Meter

Variable Area Flow Meter

Ultrasonic Flow Meter

Electromagnetic Flow Meter

Specifications

Specifications:

- Sensor Wetted Materials: 316 SS Standard

- Flows: 0.1 kg/h to 1,000,000 kg/h relative to water

- Accuracy:

- +/- 0.2% or 0.5% of reading in gas or water.

- 0.1% available on special orders.

- Turndown Ratio: 20:1

- Repeatability: +/- 0.02% of reading

- Connection Sizes: 3/8″ to 8″ 150# ANSI Flange. Up to 12″ available custom

- 1/4″ Swage to 3/4″ Swage and TriClover Sanitary fittings.

- OLED Display

- Temperature Accuracy: +/- 1 Deg C

- Temperature:

- Gas: -58°F (-50°C) to 257°F (125°C)

- Ambient: -40°F (-40°C) to 131°F (55°C)

- Power Requirement: 24 VDC or 85-220 VAC, 15 Watts max

- Output signals: 4–20 mA, 0-10 KHz and 0-10VDC Optional

- Digital communications: Modbus RTU Standard, HART

- Pressure: 4.0 MPa, 580 PSIG, Up to 25 MPa (3,600 PSIG)

- Display: Flow rate, Total flow, Temperature, and Density

- Wiring connection to enclosure size: M20 x 1.5 or NPT Optional

- Certifications

- Explosion Proof Rating: UL/CSA Class 1 Div 1 standard.

- Electronics Enclosure NEMA 4X / IP67

- Fluids/ Applications: Liquids (clean/ dirty/viscous/ slurries) clean /liquified gases

- Bi-Directional flow measurement

Coriolis Flow Meter Specifications

| Flange Types | ANSI classes - 300, 600, 900 and 1500 (per ANSI B16.5) |

| Specific Gravity | 0.35 to 1.50 |

| Accuracy Limits | accuracy limits (AGA 9 compliant) are:

• ± 1% without a flow calibration (10” and smaller line sizes)

• ± 0.7% without a flow calibration (for 12” and larger line sizes)

• ±0.1% with a flow calibration

Model(s) 3411 and 3412 accuracy limits are:

• ± 1.5% without a flow calibration |

| Power | Meter

• 10.4 VDC to 36 VDC

• 11 W power consumption (15 W maximum)

Serial cable

• Belden #9940 or equivalent (22 gauge)

— Capacitance (pF/m) 121.397 (conductor to conductor)

— capacitance (pF/m) 219.827 (conductor to other conductor and shield)

— Resistance (DC) DCR @ 20° C (recommended)

Ethernet cable

• Cat-5 Standard 100 Mbps

Frequency (see Table 3-1)

22 AWG wire characteristics areas follows:

— Capacitance = 20 pF/ft or 20 nF/1000 ft (between two wires)

— Resistance = 0.0168 Ohms/ft or 16.8 Ohms/1000 ft

— Pull-up voltages 24 VDC |

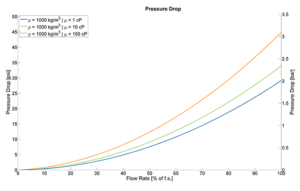

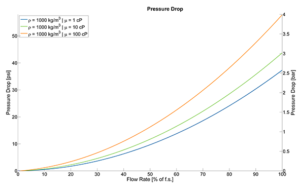

Pressure Drop

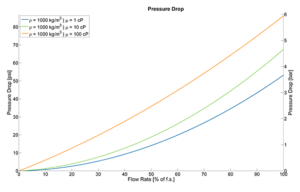

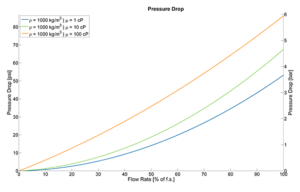

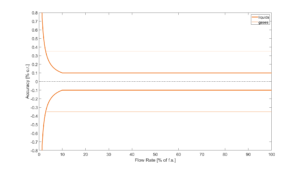

1/2″ Pressure Drop

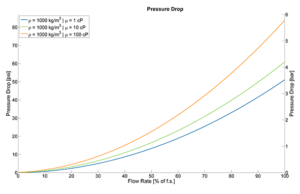

1″ Pressure Drop

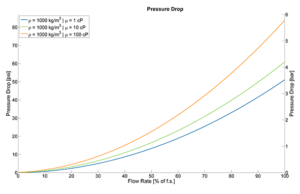

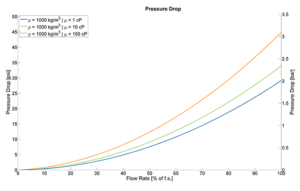

2″ Pressure Drop

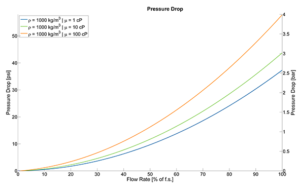

3” Pressure Drop

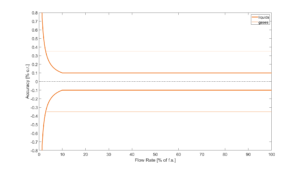

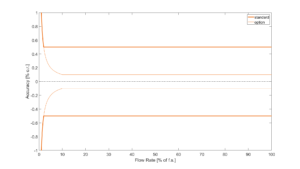

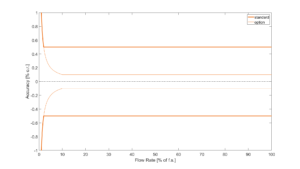

Accuracy

Mass Accuracy

Volumetric Accuracy

Installation

Installing a Coriolis flow meter involves several critical steps to ensure accurate measurement and reliable operation. Here’s a comprehensive guide for proper installation:

Site Preparation

- Verify Specifications: Ensure that the flow meter’s specifications match the requirements of your application, including flow rate, pressure, temperature, and fluid characteristics.

- Check Mounting Requirements: Review the manufacturer’s guidelines for installation, including any necessary clearances and mounting orientations.

Piping and Mounting

- Pipe Alignment: Install the flow meter in a location with straight, uninterrupted piping sections before and after the meter. This minimizes measurement errors due to turbulence or swirl. Typically, manufacturers recommend at least 10 to 20 pipe diameters of straight run upstream and 5 diameters downstream.

- Support and Vibration: Securely mount the meter using appropriate supports to minimize vibration and stress on the device. Ensure that the mounting brackets or supports do not interfere with the meter’s operation.

- Orientation: Follow the manufacturer’s recommendations for mounting orientation (horizontal or vertical) to ensure proper operation. Some meters are sensitive to orientation, which can affect accuracy.

Connections

- Fluid Connections: Ensure that the pipe connections are clean and free of debris. Use the appropriate gaskets and seals to prevent leaks. The connections should be properly torqued to avoid stressing the flow meter.

- Flange or Threaded Connections: Install the meter using the recommended flange or threaded connections. Avoid using excessive force, which can damage the meter.

Electrical and Communication

- Wiring: Connect the meter to the power supply and signal outputs according to the manufacturer’s wiring diagram. Ensure that all electrical connections are secure and properly insulated.

- Calibration and Configuration: After installation, calibrate the flow meter as per the manufacturer’s instructions. Configure any necessary settings using the meter’s control interface or software.

System Testing

- Leak Check: Before fully commissioning the system, check for any leaks around the flow meter connections and correct them if necessary.

- Function Test: Perform a test run of the system to verify that the flow meter is operating correctly. Check for accurate readings and ensure that the meter’s diagnostics are functioning properly.

Documentation and Maintenance

- Record Keeping: Document the installation process, including any configuration settings and calibration details.

- Regular Maintenance: Follow the manufacturer’s recommendations for regular maintenance and calibration to ensure continued accuracy and reliability.

Proper installation is crucial for the performance and longevity of a Coriolis flow meter. Adhering to these guidelines will help ensure accurate measurements and reliable operation in your industrial applications.

Maintenance

Maintaining a Coriolis flow meter is essential for ensuring its accuracy and longevity. Regular maintenance helps prevent issues that could affect performance or lead to costly downtime. Here’s a detailed guide on maintenance procedures for Coriolis flow meters:

Routine Inspection

- Visual Checks: Periodically inspect the flow meter for any signs of physical damage, leaks, or corrosion. Ensure that mounting hardware and connections are secure and not showing signs of wear.

- Check for Vibration: Verify that the meter is not experiencing excessive vibrations. Ensure that the installation supports are intact and that there are no external sources of vibration affecting the meter.

Cleaning

- External Cleaning: Clean the exterior of the flow meter with a soft, damp cloth to remove dust and debris. Avoid using abrasive materials or harsh chemicals that could damage the surface.

- Internal Cleaning: Depending on the fluid being measured and the operating conditions, periodic internal cleaning may be necessary to prevent buildup or contamination. Follow the manufacturer’s recommendations for cleaning procedures and use appropriate cleaning agents.

Calibration and Verification

- Scheduled Calibration: Regularly calibrate the flow meter according to the manufacturer’s guidelines. Calibration intervals may vary based on the application and operating conditions.

- Verification: Perform periodic verification checks against a known standard or reference to ensure measurement accuracy. This can help detect drift or performance issues before they affect operations.

Software and Firmware Updates

- Update Firmware: Regularly check for and apply firmware updates from the manufacturer to ensure that the meter’s software is up to date with the latest features and improvements.

- Software Configuration: Review and adjust the configuration settings as needed to accommodate any changes in the process or measurement requirements.

Diagnostics and Troubleshooting

- Monitor Diagnostics: Utilize the flow meter’s built-in diagnostic tools to monitor its performance. Check for any error codes or alerts that indicate potential issues.

- Troubleshoot Issues: If problems are detected, follow the manufacturer’s troubleshooting guide to diagnose and resolve the issue. This may involve checking connections, verifying calibration, or replacing faulty components.

Documentation

- Record Keeping: Maintain detailed records of all maintenance activities, including inspections, calibrations, cleaning, and any repairs. Document any changes made to the meter’s configuration or settings.

7. Training and Procedures

- Operator Training: Ensure that personnel responsible for operating and maintaining the flow meter are properly trained and familiar with the maintenance procedures and safety protocols.

- Update Procedures: Regularly review and update maintenance procedures to reflect any changes in operational requirements or manufacturer recommendations.

Safety Considerations

- Follow Safety Guidelines: Always adhere to safety guidelines and protocols when performing maintenance. This includes wearing appropriate personal protective equipment (PPE) and following lockout/tagout procedures if necessary.

By following these maintenance procedures, you can ensure the continued accuracy and reliability of your Coriolis flow meter, ultimately contributing to optimal performance and reduced downtime in your operations.

Q&A

A Q&A, or Question and Answer session, is an interactive format used to facilitate discussion. It is also used to provide information about a specific topic. In the case of Coriolis flow meters, a Q&A session would serve as an opportunity for participants to ask questions about the functioning, installation, calibration, applications, and troubleshooting of Coriolis flow meters.

During the Q&A session, experts or individuals with expertise in Coriolis flow meters would provide insightful and informative responses to these questions. Additionally, they may share their knowledge, experiences, and best practices to help attendees better understand and utilize Coriolis flow meters effectively. Moreover, the session would foster an open and collaborative environment, catering to the specific interests and concerns of those seeking information about Coriolis flow meters.

Coriolis flow meters are widely used in industrial applications for accurate and reliable measurement of fluid flow. In this Q&A Coriolis Flow Meters, we will provide an overview of what Coriolis flow meters are, how they work, and some benefits they offer. Let’s get started!

Q: What is a Coriolis flow meter?

A: A Coriolis flow meter is a type of mass flow meter that measures the mass flow rate of a fluid directly. It works by inducing vibration in the measuring tube and measuring the phase shift between two points on the tube.

Q: What fluids can be measured with a Coriolis flow meter?

A: Coriolis flow meters can be used to measure the mass flow rate of a wide range of fluids, including liquids, gases, slurries, and even multiphase flows.

Q: What are the advantages of using a Coriolis flow meter?

A: The advantages of using a Coriolis flow meter include its high accuracy, direct mass flow measurement, and ability to measure a wide range of fluids. Finally, they are also very versatile and can be used in a variety of industries and applications.

Q: What are the main applications of Coriolis flow meters?

A: Coriolis flow meters are commonly used in the food and beverage industry, pharmaceuticals, chemicals, oil and gas, and many other industries that require accurate and reliable flow measurements.

Q: How do you install and maintain a Coriolis flow meter?

A: Coriolis flow meters should be installed in a location where the fluid is fully developed, and the flow is uniform. Maintenance typically involves periodic calibration and cleaning of the measuring tube to prevent the buildup of solids or other contaminants that may affect the accuracy of the measurement.

Q: What are the key factors to consider when selecting a Coriolis flow meter?

A: When selecting a Coriolis flow meter, it is important to consider factors such as the expected flow rate, viscosity of the fluid, pressure, and temperature range, accuracy requirements, and the environment in which the meter will be installed.

Q: How does a Coriolis flow meter compare to other types of flow meters?

A: Compared to other types of flow meters, such as turbine, magnetic, or ultrasonic flow meters, Coriolis flow meters offer the advantage of direct mass flow measurement with high accuracy and reliability. Additionally, they can also measure a wide range of fluids and are not affected by changes in fluid properties, such as temperature or viscosity. However, they can be more expensive and require more careful installation and maintenance than some other types of flow meters.

Q: What is a Coriolis flow meter?

A: A Coriolis flow meter is a type of flow meter that measures the mass flow rate of fluids. Additionally, It works based on the principle of the Coriolis effect, which causes a vibrating tube to twist when a fluid flows through it. Finally, the degree of twist is proportional to the mass flow rate of the fluid, allowing for accurate measurement.

A: Coriolis flow meters have several advantages, including:

-

- High accuracy and precision

-

- Able to measure both liquid and gas flows

-

- No moving parts that can wear out or be damaged

-

- A wide range of flow rates can be measured

-

- Ability to measure density and temperature as well

Q: What applications are Coriolis flow meters commonly used in?

A: Coriolis flow meters are used in a wide range of industries and applications, including:

-

- Chemical and petrochemical processing

-

- Food and beverage production

-

- Pharmaceutical manufacturing

-

- Oil and gas exploration and production

-

- Water and wastewater treatment

-

- Mining and minerals processing

Q: What factors should be considered when selecting a Coriolis flow meter?

A: When selecting a Coriolis flow meter, several factors should be considered, including:

-

- Flow rate range: Make sure the flow meter can measure the required range of flow rates.

-

- Fluid type: Ensure that the flow meter is compatible with the fluid being measured, including its viscosity and corrosiveness.

-

- Process conditions: Consider the process pressure and temperature, as well as any potential vibrations or shocks.

-

- Accuracy requirements: Determine the required level of accuracy and precision for the application.

-

- Installation requirements: Consider the space available for installation, as well as any piping or wiring requirements.

Q: What maintenance is required for Q&A Coriolis Flow Meters?

A: Coriolis flow meters are relatively low maintenance, with no moving parts to wear out or be damaged. However, regular calibration may be necessary to ensure accurate readings. In addition, the flow meter should be inspected periodically for any signs of damage or wear. Finally, any necessary repairs should be made promptly.

Buy Coriolis Flow Meter

Advantages / Disadvantages

Advantages of Coriolis Flow Meters

High Accuracy: Coriolis flow meters are known for their exceptional accuracy in measuring flow rates of liquids and gases, making them suitable for applications where precision is critical.

Mass Flow Measurement: Unlike some other flow meter types, Coriolis meters can directly measure mass flow rate, independent of fluid properties such as temperature, pressure, or density variations.

Multivariable Measurement: Coriolis flow meters can provide additional measurements such as density, temperature, and concentration along with flow rate, offering comprehensive process data in a single device.

Wide Range of Applications: These meters can be used across various industries, including oil and gas, chemical processing, food and beverage, pharmaceuticals, and more, due to their versatility and capability to handle different types of fluids.

Low-Pressure Drop: Coriolis flow meters typically have a low-pressure drop compared to some other flow measurement technologies, preventing any significant impact on the overall system performance.

Disadvantages of Coriolis Flow Meters

Cost: Coriolis flow meters are generally more expensive upfront compared to some other flow meter types, which can be a significant investment for some applications.

Susceptibility to Vibrations: External vibrations or mechanical disturbances can affect the performance of Coriolis flow meters, leading to potential inaccuracies in flow measurements.

Fluid Compatibility: Certain fluids, especially those with high viscosity, solids content, or corrosive properties, may pose challenges for Coriolis flow meters, limiting their suitability for some applications.

Size and Weight: Coriolis meters can be larger and heavier than other flow meter technologies, which may be a constraint in installations where space is limited or weight considerations are important.

Maintenance Requirements: Coriolis flow meters can have complex internal components that require regular maintenance and calibration to ensure accurate and reliable performance, adding to the overall cost of ownership.

While Coriolis flow meters offer superior accuracy and versatility in flow measurement, it’s essential to consider these advantages and disadvantages to determine if they are the right choice for a specific application based on factors such as budget, fluid properties, environmental conditions, and maintenance capabilities.

Applications

Coriolis flow meters are versatile devices widely used across various industries for measuring the flow of liquids and gases. Some common applications of Coriolis flow meters include:

Oil and Gas Industry: Coriolis flow meters are utilized for measuring crude oil, refined products, natural gas, and various fluids in upstream, midstream, and downstream processes, such as testing, custody transfer, pipeline monitoring, and blending operations.

Chemical Processing: These meters are employed in chemical plants for accurate measurement of corrosive chemicals, solvents, acids, and other liquids used in production processes, ensuring precise flow control, batching, and inventory management.

Food and Beverage Production: Coriolis flow meters play a vital role in the food and beverage industry for measuring ingredients, additives, flavorings, and beverages with high accuracy, hygiene standards, and compliance with regulatory requirements.

Pharmaceutical Manufacturing: In pharmaceutical facilities, Coriolis flow meters are used for monitoring and dispensing ingredients, conducting batch processing, and ensuring precise flow rates of pharmaceutical solutions and products.

Water and Wastewater Treatment: These meters are employed in water treatment plants for measuring water flow, dosing chemicals, monitoring sludge, and managing processes related to disinfection, filtration, and distribution systems.

HVAC Systems: Coriolis flow meters are integrated into heating, ventilation, and air conditioning systems to measure the flow of water, glycol, or other fluids for efficient heat transfer, energy management, and building comfort control.

Petrochemical Industry: Coriolis flow meters are critical for measuring feedstock, petrochemical products, lubricants, and additives in refineries, petrochemical plants, and storage terminals to optimize production processes and ensure product quality.

Pulp and Paper Manufacturing: These meters are used in pulp and paper mills to measure pulp consistency, chemical additives, coatings, and process water flow rates for enhancing paper quality, production efficiency, and environmental sustainability.

Automotive Engineering: Coriolis flow meters find applications in automotive testing facilities for measuring fuel consumption, emissions, lubricants, coolants, and other fluids in engine testing, vehicle development, and research projects.

Aerospace and Defense: These meters are utilized in aerospace and defense industries for measuring hydraulic fluids, fuels, propellants, lubricants, and cooling fluids in aircraft, spacecraft, missiles, and military vehicles to ensure operational safety and performance.

These examples illustrate the diverse range of applications where Coriolis flow meters are employed to provide accurate flow measurement, improve process efficiency, enhance product quality, and ensure regulatory compliance in various industrial sectors.

Drawings

The Coriolis Flow Meter and Mass Meters are instruments used to measure the mass flow rate of a fluid. They operate on the principle of Coriolis force, which is a force that acts on a mass moving in a rotating system. A Coriolis flow meter consists of a U-shaped tube that is oscillated at a specific frequency. When a fluid flows through the tube, it causes a twisting motion in the tube due to the Coriolis force acting on the fluid. This twisting motion is proportional to the mass flow rate of the fluid. Also, it is measured by sensors placed at the inlet and outlet of the tube.

The Coriolis Flow Meter and Mass Meters are instruments used to measure the mass flow rate of a fluid. They operate on the principle of Coriolis force, which is a force that acts on a mass moving in a rotating system. A Coriolis flow meter consists of a U-shaped tube that is oscillated at a specific frequency. When a fluid flows through the tube, it causes a twisting motion in the tube due to the Coriolis force acting on the fluid. This twisting motion is proportional to the mass flow rate of the fluid. Also, it is measured by sensors placed at the inlet and outlet of the tube.