Description

Introduction to Thermal Oil Pumps

Introduction to Thermal Oil Pumps

Thermal oil pumps are specialized devices designed to circulate heat transfer fluids, such as thermal oils, through industrial systems. They play a vital role in enabling efficient heat transfer in high-temperature processes. Industries like chemical processing, oil and gas, food production, and manufacturing rely on them for precise temperature control.

Unlike water-based systems, thermal oil systems operate at temperatures often exceeding 300°C. Yet they do not require high-pressure environments. This makes thermal oil pumps essential in applications demanding consistent, high heat without the risks linked to steam-based systems.

The Role of Thermal Oil Pumps in Industrial Applications

Thermal oil pumps form the core of thermal fluid systems. They move heat transfer fluids through heaters, exchangers, and process equipment to maintain temperature control. These pumps handle viscous fluids at extreme temperatures, ensuring both efficiency and safety.

In chemical plants, they support reactions that need stable temperature ranges. In food processing, they aid in tasks like cooking and drying. Their performance under extreme conditions makes them critical for industries that demand reliability.

They also improve energy efficiency. Thermal oils retain heat better than steam, reducing energy loss. Since they don’t require pressure management, the system runs more efficiently. This cuts operational costs and enhances process control.

Design and Construction of Thermal Oil Pumps

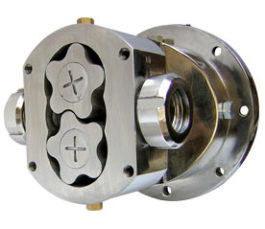

Thermal oil pumps are built to perform in high-temperature environments. Most designs are centrifugal, using a rotating impeller to move fluid. Engineers select materials like stainless steel or cast iron to resist heat, corrosion, and thermal expansion.

Seals and bearings must tolerate intense heat and prevent leaks. Failures in these components can lead to hazardous conditions. Many pumps include cooling systems—either air- or water-cooled—to protect internal parts from overheating.

Some modern designs feature magnetic drive systems. These remove the need for mechanical seals, reducing the risk of leakage and boosting system reliability.

Types of Thermal Oil Pumps

Different applications require different pump configurations. Single-stage centrifugal pumps are suitable for moderate flow and pressure needs. Multi-stage pumps serve high-pressure applications, like those found in large industrial setups.

Inline pumps work well in compact systems with limited space. Base-mounted pumps offer higher durability for demanding applications. The correct pump depends on flow rate, pressure, temperature, and fluid viscosity. This variety ensures industries can match the right pump to their needs.

Key Features and Technologies

Modern thermal oil pumps come with advanced features for better performance and safety. Many use variable frequency drives (VFDs), which adjust pump speed to match system demand. This reduces energy use and mechanical wear.

Some pumps include sensors that monitor temperature, pressure, and flow in real time. These sensors support predictive maintenance and help detect problems early.

To prevent hazards, many pumps use double mechanical seals or seal-less magnetic drives. These designs reduce the chance of leaks that could lead to fire or environmental damage. Fail-safes like automatic shut-off systems add another layer of protection. These innovations ensure that pumps meet the latest safety and efficiency standards.

Advantages of Thermal Oil Pumps

Thermal oil pumps offer several key benefits over steam-based systems. They can operate at high temperatures without needing pressurized systems, which reduces infrastructure costs. This is ideal in industries like asphalt production, where constant high heat is essential.

Thermal oils retain heat longer than steam, allowing for more efficient energy use. These systems also need less maintenance than steam systems, which often face scaling and corrosion problems.

Because of their durable construction, thermal oil pumps have long service lives. This reduces downtime and replacement costs. Over time, they help lower both operational and maintenance expenses.

Challenges and Considerations

Despite their benefits, thermal oil pumps come with challenges. One key issue is fluid degradation. Over time, thermal oil can thicken, increasing wear on pump components. Regular monitoring and maintenance are critical to prevent system failure.

Operating at high temperatures also demands high-quality materials and precise engineering, which can raise upfront costs. In addition, these systems require trained personnel. Mishandling can result in fires or leaks. Routine inspections and staff training are essential for safe operation.

Future Trends in Thermal Oil Pump Technology

As industries aim for greater efficiency and sustainability, thermal oil pumps are evolving. Manufacturers are developing smarter, more energy-efficient designs. Many new models include IoT-enabled sensors for real-time optimization.

Advances in materials are expanding the pumps’ capabilities. New materials allow pumps to handle higher temperatures and more aggressive fluids. This opens doors to new applications.

Eco-friendly trends are also influencing thermal oil systems. Biodegradable and low-toxicity thermal fluids are emerging. Pumps must adapt to work with these safer alternatives, further supporting green industrial practices.

Conclusion

Thermal oil pumps are essential for high-temperature industrial processes. Their ability to handle extreme heat without pressure, along with their reliability and efficiency, makes them indispensable across many industries. While they present some challenges, these can be managed through smart design and regular maintenance.

With ongoing advancements in smart technology and materials, thermal oil pumps will continue to play a crucial role in industrial heat transfer. Their future lies in becoming more efficient, safer, and environmentally friendly.

Also check out, “Pump Systems“