Sight Flow Indicators

Sight flow indicators are essential tools used in piping systems to visually monitor the flow of fluids. Typically crafted with a durable transparent viewing window, these indicators allow operators to observe the movement, clarity, and color of fluids passing through the system. Commonly constructed with high-quality materials like stainless steel for durability and corrosion resistance, sight flow indicators provide real-time visual feedback on flow rates, aiding in the detection of blockages, impurities, or irregularities in the fluid stream. Equipped with adjustable flow indicators or rotors, these devices respond to changes in flow rate by spinning or moving, offering a clear indication of fluid movement. Some models also feature built-in lighting systems to enhance visibility in various conditions. Overall, sight flow indicators play a crucial role in industries such as chemical processing, food and beverage, pharmaceuticals, and water treatment, ensuring efficient and safe operation of fluid systems through visual flow monitoring.

Description

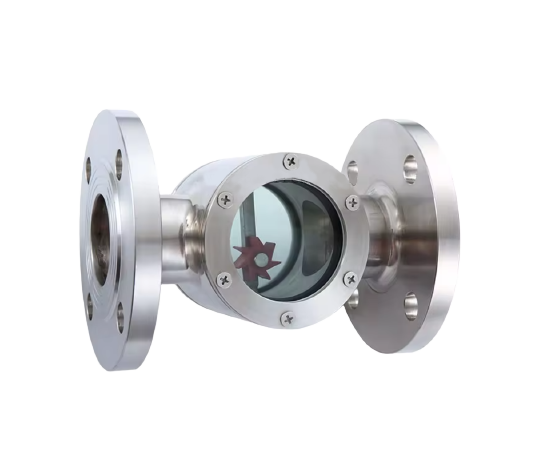

Sight flow indicators in stainless steel are essential devices designed to provide visual insight into the flow of fluids within a piping system. These indicators are typically constructed using high-quality stainless steel. A Stainless grade such as 304 or 316 stainless steels, known for its durability, corrosion resistance, and high strength.

Sight flow indicators in stainless steel are essential devices designed to provide visual insight into the flow of fluids within a piping system. These indicators are typically constructed using high-quality stainless steel. A Stainless grade such as 304 or 316 stainless steels, known for its durability, corrosion resistance, and high strength.

One common design for sight flow indicators includes a transparent viewing window made of robust glass or durable acrylic material. Additionally, this is set within a stainless-steel housing. The transparent window allows operators to visually inspect the movement, color, and clarity of the fluid passing through the system. This visual feedback can be crucial for monitoring flow rates, detecting blockages, observing impurities, or identifying any irregularities in the fluid stream.

Stainless steel sight flow indicators are often equipped with adjustable flow indicators or rotors inside the housing. These indicators or rotors are immersed in the fluid flow and respond to changes in flow rate by spinning or moving, providing a clear visual indication of fluid movement. This dynamic element aids in quick and easy flow rate monitoring without the need for additional instrumentation.

Illumination in Sight Flow Indicators

Additionally, stainless steel sight flow indicators may incorporate features such as built-in lighting systems. This is used to enhance visibility in low-light conditions or the presence of opaque fluids. LED lights or illumination devices integrated into the indicator housing can improve the visibility of the fluid flow. As a result, it makes it easier for operators to observe and assess the flow conditions accurately. Finally, wiper blades can also be added so if the Interior is coated a wiper will allow the viewing window to be cleaned.

Overall, sight flow indicators in stainless steel are reliable, sturdy, and versatile tools. Moreover, these are used in various industries such as chemical processing, food and beverage, pharmaceuticals, and water treatment. Their robust construction, coupled with the visual insights they provide. As a result, it makes them essential components for ensuring the efficient and safe operation of fluid systems.

Specifications

Sight flow indicators make monitoring liquids inside a pipe easy and efficient. The device is installed into a pipe and offers a visual reference for liquid flow and direction. Operators can also see the clarity and color of fluids via a window.

Connection: 1/2 – 2″ Inch FNPT

Materials:

Body: 304 Stainless Steel, Tempered Glass

Seal: PTFE

Impeller: PTFE (Red)

Maximum Pressure: 232 psig (16 bar)

Maximum Temperature: 392°F

For use with liquids. Directional arrow on the unit specifies direction of flow and should be installed accordingly.

Warranty:1 Year Conditional Manufacturer Warranty

Q&A

Q: What is the purpose of a sight flow indicator?

A: Sight flow indicators are used to visually monitor the flow of fluids within a piping system. They provide operators with a clear view of the movement, color, and clarity of liquids passing through the system, enabling them to detect blockages, impurities, or irregularities in the flow without the need for additional instrumentation.

Q: How do sight flow indicators work?

A: Sight flow indicators typically consist of a transparent viewing window (often made of glass or acrylic) set within a housing. As the fluid flows through the system, operators can observe the movement through this window. Some indicators also include flow indicators or rotors that respond to changes in flow rate by spinning or moving, providing a visual indication of fluid movement.

Q: Where are sight flow indicators commonly used?

A: Sight flow indicators find application in a wide range of industries and processes. They are commonly employed in chemical processing plants, food and beverage production, pharmaceutical manufacturing, water treatment facilities, HVAC systems, oil and gas industries, petrochemical plants, power generation facilities, and more, where visual monitoring of fluid flow is crucial.

Q: What are the advantages of using sight flow indicators?

A: Sight flow indicators offer several advantages, including real-time visual monitoring of flow conditions, ease of inspection for detecting flow issues, quick troubleshooting capabilities, enhanced safety through accurate flow monitoring, and versatility in applications across different industries.

Q: Are there any drawbacks to using sight flow indicators?

A: Despite their advantages, sight flow indicators have limitations. They may not provide detailed quantitative data on flow rates or pressure, their effectiveness can be hindered in low-light or opaque fluid environments, they require regular maintenance to ensure clear visibility, they can be costly compared to other monitoring devices, and proper installation is crucial for accurate readings.

Advantages / Disadvantages

Advantages of Sight Flow Indicators

Visual Monitoring: Sight flow indicators provide real-time visual feedback on fluid flow, allowing operators to observe the movement, color, and clarity of liquids passing through the system.

Easy Inspection: They facilitate easy visual inspection of flow conditions, helping detect blockages, impurities, or irregularities in the fluid stream without the need for additional instrumentation.

Quick Troubleshooting: Sight flow indicators enable operators to quickly identify flow issues, such as low flow rates or obstructions, leading to faster troubleshooting and maintenance.

Enhanced Safety: By offering a visual indication of flow rates and conditions, these devices contribute to enhanced safety by enabling operators to monitor fluid movement accurately.

Versatility: Sight flow indicators find applications across various industries, including chemical processing, food and beverage, pharmaceuticals, water treatment, and more, showcasing their versatility.

Disadvantages of Sight Flow Indicators

Limited Data: Sight flow indicators primarily offer visual feedback and do not provide detailed quantitative data on flow rates or pressure, which may be necessary in certain applications.

Dependence on Visibility: In environments with poor lighting or opaque fluids, visibility through the transparent window of sight flow indicators may be compromised, affecting monitoring effectiveness.

Maintenance: Regular maintenance may be required to ensure the transparent viewing window remains clear and free from obstruction, especially in applications where fluids may cause build-up or deposits.

Cost: Depending on the design and materials used, sight flow indicators can be relatively costly compared to other flow monitoring devices, which could impact budget considerations.

Installation Requirements: Proper installation and alignment of sight flow indicators are crucial for accurate monitoring, and improper setup may lead to inaccurate readings or potential leaks in the system.

Applications

Sight flow indicators find application in a variety of industries and processes where visual monitoring of fluid flow is essential. Some common applications include:

Chemical Processing: Sight flow indicators are used to monitor the flow of various chemicals through pipelines, reactors, and processing equipment in chemical plants.

Food and Beverage: In the food and beverage industry, sight flow indicators are employed to observe the flow of liquids like beverages, syrups, and dairy products during production and packaging.

Pharmaceuticals: Sight flow indicators help in monitoring the flow of pharmaceutical ingredients and products to ensure proper mixing, blending, and processing.

Water Treatment: These indicators play a crucial role in water treatment facilities for monitoring the flow of water, chemicals, and additives in treatment processes.

HVAC Systems: Sight flow indicators are used in heating, ventilation, and air conditioning systems to monitor the flow of water, coolant, or refrigerants within the system.

Oil and Gas Industry: In oil and gas applications, sight flow indicators help in monitoring the flow of oil, gas, and other fluids in pipelines and processing equipment.

Petrochemical Plants: Sight flow indicators are essential for monitoring the flow of various fluids in petrochemical processes such as refining and production.

Power Generation: In power plants, sight flow indicators are used to monitor the flow of cooling water, steam, and other fluids in boilers, turbines, and other equipment.

These are just a few examples of the diverse applications where sight flow indicators play a crucial role in ensuring efficient and safe operation by providing real-time visual feedback on fluid flow.

Drawings

Sight flow indicators in stainless steel are essential devices designed to provide visual insight into the flow of fluids within a piping system. These indicators are typically constructed using high-quality stainless steel. A Stainless grade such as 304 or 316 stainless steels, known for its durability, corrosion resistance, and high strength.

Sight flow indicators in stainless steel are essential devices designed to provide visual insight into the flow of fluids within a piping system. These indicators are typically constructed using high-quality stainless steel. A Stainless grade such as 304 or 316 stainless steels, known for its durability, corrosion resistance, and high strength.