Motors

Motors designed for explosive environments are engineered to operate safely in areas where there’s a high risk of explosion. In addition, they comply with international safety standards such as ATEX and IECEx. Also, the ATEX directive is the European standard for equipment. This is intended for use in potentially explosive atmospheres.

These motors are classified according to the level of explosion protection they provide. Also, they are divided into categories for gas environments and dust environments. In addition, the design of these motors meets specific requirements for each zone. This includes the use of explosion-proof enclosures and appropriate electrical components.

Motors for areas with hazardous dust are known as Dust Ignition Proof or DIP motors. Furthermore, these are used in atmospheres where explosive dust surrounds the motor. Also, where dust settles under its weight on the motor.

The IP (Ingress Protection) ratings indicate the level of protection provided by an electrical enclosure against the ingress of solid objects and liquids. In addition, when selecting a motor for use in explosive environments. In addition, it’s crucial to consider the ATEX and IP ratings, as well as the specific requirements for the environment in which the motor will be used.

For more detailed information, it’s recommended to contact the motor manufacturer or a qualified professional who understands the risks and requirements associated with these environments. Finally, they can guide the selection and installation of motors for explosive environments.

Showing all 6 resultsSorted by popularity

-

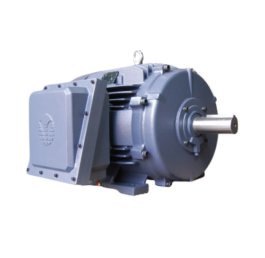

NEMA Explosion Proof Motor

Price range: $ 968.00 through $ 24,847.00Select options This product has multiple variants. The options may be chosen on the product page -

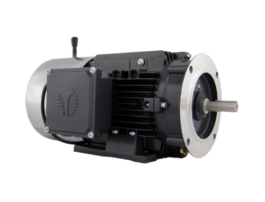

NEMA Premium TEFC Motors – Green Line

Read more -

NEMA Premium TEFC Motors – Cobra Line

Price range: $ 309.00 through $ 578.00Select options This product has multiple variants. The options may be chosen on the product page -

Water Ring Vacuum Pumps

$ 1,456.00Select options This product has multiple variants. The options may be chosen on the product page -

Rotary Lobe Pumps

Price range: $ 3,800.00 through $ 7,600.00Select options This product has multiple variants. The options may be chosen on the product page -

Sale

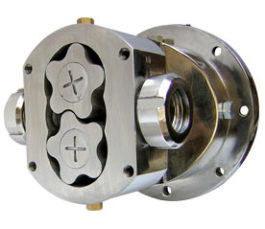

Rotary Gear Pumps

Price range: $ 2,125.00 through $ 6,879.00Select options This product has multiple variants. The options may be chosen on the product page