Industrial classification systems with division or class with explosion-proof areas typically refers to specific zones in a facility where the atmosphere can become explosive. Also, it is due to the presence of flammable gases, vapors, or dust. Additionally, these areas require specialized equipment and design considerations to prevent the ignition of hazardous materials.

Specific characteristics of a class/division with explosion-proof areas may include:

Classification Systems: Areas are classified based on the type and likelihood of hazardous materials present. Also, common classification systems include Class I (flammable gases or vapors), Class II (combustible dust), and Class III (combustible fibers).

Protection Methods: Equipment installed in explosion-proof areas must meet stringent safety standards to prevent sparks or hot surfaces from igniting the surrounding atmosphere. Finally, this can involve using explosion-proof enclosures, intrinsically safe devices (Pressure, Flow, Level and Temperature), or purging/pressurization systems.

Regulations: Compliance with national and international standards, such as NEC (National Electrical Code) in the U.S., is crucial in these areas to ensure safety and prevent accidents.

Safety Protocols: Strict safety protocols, including proper maintenance, training of personnel, and regular inspections, are essential to minimize the risk of explosions in these classification systems areas.

Emergency Response: Facilities with explosion-proof areas should have robust emergency response plans in place. Furthermore, this includes evacuation procedures, communication protocols, and firefighting measures specific to hazardous materials.

Overall, managing an industrial division with explosion-proof areas requires a comprehensive approach to safety that encompasses proper zoning, equipment selection, employee training, and adherence to regulations. Moreover, this helps mitigate the risks associated with potentially explosive atmospheres.

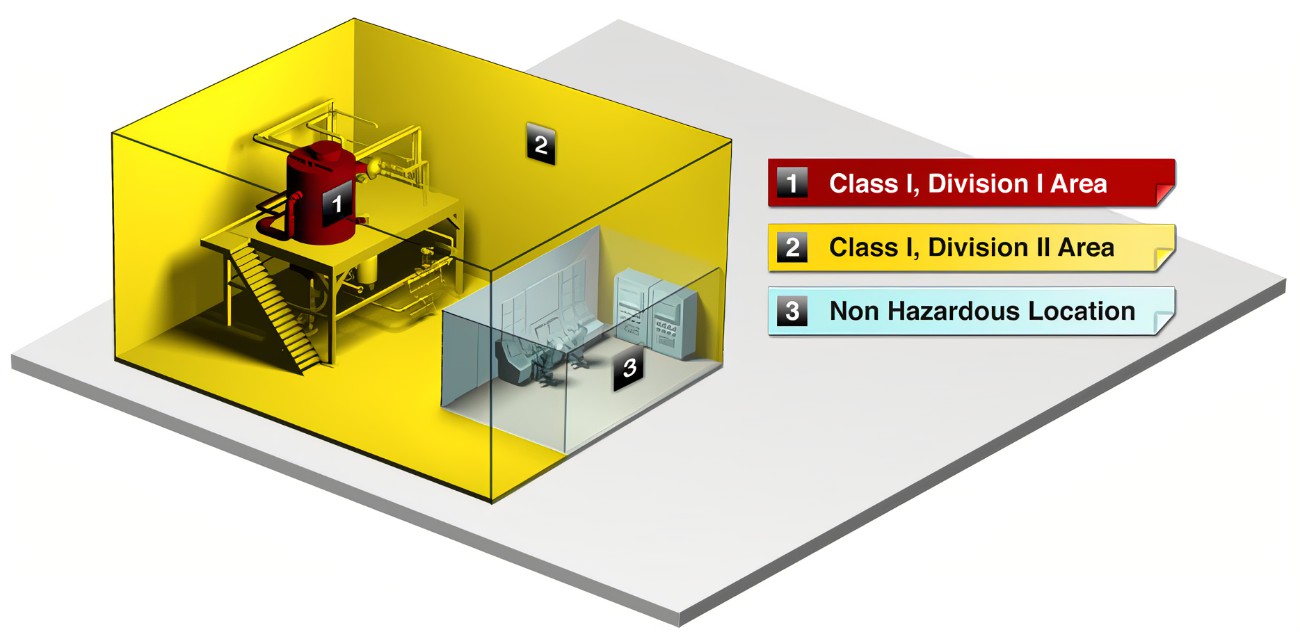

Class / Division

The class/division system, used in North America, defines and classifies specific hazardous area conditions. Class: The nature of hazards, such as gas, vapor, dust and fibers. There are 3 classes in total. Also, class I is important for the petrol/chemical industry since it covers flammable gases or vapors, with enough to cause explosive or ignitable mixtures. Division: The probability of hazardous material being present. There are only 2. Furthermore, division 1 represents a high probability, while division 2 is low. Group: The type of hazardous material. These range from A through G, with each group containing loosely related flammable substances. Finally, the list covers over 50 of them, from acetylene to zinc.

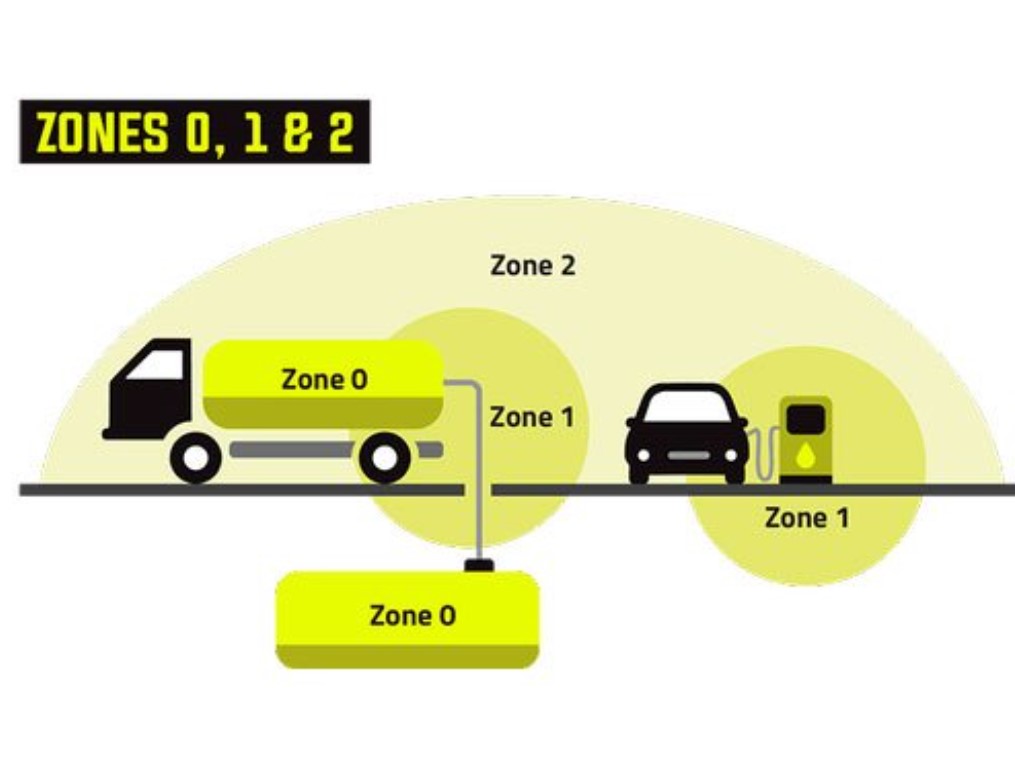

Zone

The Zone system is used in Europe, Asia and elsewhere internationally. In addiiton, the Zone is gradually being adopted in North America. Zone: The general nature of material (e.g., gas or dust) and probability of hazardous material being present in ignitable concentration. •Zone 0 covers for long periods of time. •Zone 1 covers what is produced under normal operating conditions. •Zone 2 covers gases that are not likely to occur and do so for a short period of time. •Similarly, Zone 20 covers fibers that are present continuously or long periods of time. •Zone 21 covers normal operating conditions. •Zone 22 covers ones that are not likely to occur and do so for short periods of time. Additionally, the Group: The type of hazardous material and (partly) location. Group I cover mines. Also, Group II covers explosive gas, while Group III covers explosive dust.

IP

An IP number identifies the level of protection provided by an enclosure or housing. additionally, it contains two digits, preceded by “IP” (e.g., IP66). Also, the first number ranges from 0-6 and relates to protection from solids by defining the size of solids or dust particles. Furthermore, the second number relates to protection from liquids and helps identify the enclosure’s liquid tolerance using varying quantities and pressures of water. Moreover, it ranges from 0-8 and ranges from no protection or dripping through heavy jet sprays and immersion/submersion. For example: IP66 = dust tight and protected against heavy water jet spray.

NEMA

NEMA is a rating system that defines the environment type in which an electrical enclosure can be used and its ability to withstand various environmental conditions. In addition, the NEMA scale ranges from 1-13, with 1 covering dust, light and indirect splashing while 13 covers dust, spraying of water, oil and noncorrosive coolants and meets oil exclusion and rust resistance design tests. Finally, in the world of mass flow products, the most common classifications are NEMA 4/4x, IP65, IP66 and IP67.

International Approvals

As the world continues to shrink when it comes to commerce and the manufacturing supply chain, international agencies and regulations are becoming increasingly important. Also, keep in mind that the required approvals are determined by the destination country, as opposed to where the instrument was manufactured. Finally, these international approvals include: •ATEX — Europe •CCOE — India •IECEx — Worldwide •KOSHA — Korea •GOST — Russia •NEPSI — China •UL, CSA — North America