Description

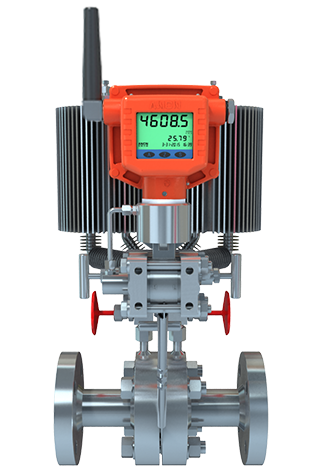

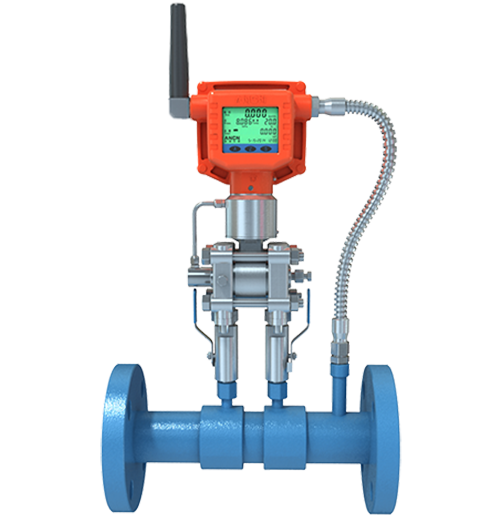

A wireless flow meter is a sophisticated device used to measure the flow rate of fluids or gases through a pipeline or conduit without the need for wired connections. This technology integrates advanced sensors, wireless communication, and often digital processing to provide accurate and real-time measurements of fluid dynamics. The advent of wireless flow meters represents a significant advancement in measurement technology, offering numerous advantages over traditional wired systems.

At its core, a wireless flow meter comprises several key components that work together to capture, process, and transmit flow data. The primary element is the sensor, which is responsible for detecting the flow of the fluid or gas. Various types of sensors can be employed, such as ultrasonic, electromagnetic, or turbine sensors, each with specific applications and measurement principles. For instance, ultrasonic flow meters use sound waves to measure flow velocity, while electromagnetic flow meters utilize magnetic fields to detect the flow of conductive fluids.

Capturing Data

The sensor captures the flow rate data, which the meter’s internal electronics then process. The processing unit, equipped with advanced algorithms and digital signal processors, ensures precise measurements and compensates for any potential errors or fluctuations in the flow. The system then prepares the processed data for transmission via wireless communication technologies.

The wireless communication system is a crucial component of the wireless flow meter. It typically utilizes radio frequency (RF) technology, such as Bluetooth, LoRA, IOT, Wi-Fi, or cellular networks, to transmit data from the meter to a remote receiver or control system. This wireless capability eliminates the need for physical wiring, making installation and maintenance simpler and more flexible. The use of wireless communication also allows for real-time data monitoring and remote access, which can be particularly advantageous in applications where the flow meter is installed in hard-to-reach locations or in environments where wiring would be challenging or hazardous.

Signals for Wireless Flow Meter

To ensure reliable wireless communication, the manufacturer equips the flow meter with a transmitter that converts the processed data into a wireless signal. The transmitter then sends this signal to a receiver or central control unit, which can be located on-site or at a remote location. The receiver decodes the signal and translates it back into actionable data, which you can display on a monitor, log for historical analysis, or use to trigger automated control systems. This seamless flow of information facilitates timely decision-making and enhances operational efficiency.

Wireless flow meters often come with additional features designed to improve their usability and functionality. For example, many models include built-in data logging capabilities, which allow the meter to store historical data for future analysis. This can be particularly useful for monitoring long-term trends, conducting performance analyses, or meeting regulatory requirements. Some wireless flow meters integrate with cloud-based platforms, allowing users to access data from anywhere with an internet connection. This cloud integration enhances the ability to perform remote diagnostics, access real-time data, and manage multiple meters from a centralized location.

Power for Wireless Flow Meter

In terms of power, wireless flow meters typically rely on batteries or energy harvesting technologies to operate. Designers create battery-powered models to be energy-efficient and extend battery life, often incorporating sleep modes and low-power communication protocols. Energy harvesting systems, on the other hand, may utilize sources such as solar power or vibration energy to generate electricity. As a result, it reduces the need for regular battery replacements and contributing to a more sustainable operation.

The advantages of wireless flow meters are numerous. They simplify installation by eliminating the need for extensive wiring. The simplified wire can reduce labor costs and minimize disruption to existing systems. The absence of physical cables also reduces the risk of mechanical damage and maintenance issues associated with wired connections. Additionally, the ability to transmit data wirelessly enables real-time monitoring and remote access. All of this can lead to quicker response times and more informed decision-making.

What to Consider

However, there are considerations to keep in mind when using wireless flow meters. Wireless communication is subject to potential interference from other electronic devices or environmental factors. All of this could impact data accuracy or signal reliability. Therefore, careful planning and consideration of the communication environment are essential to ensure optimal performance. Moreover, while wireless flow meters offer convenience and flexibility. They may also require periodic maintenance to ensure the wireless components remain functional and the power sources are adequately managed.

In summary, a wireless flow meter is a cutting-edge device that combines advanced sensing technology with wireless communication. This will measure and monitor fluid or gas flow rates. Its ability to transmit data without physical wiring streamlines installation reduces maintenance. Furthermore, this allows for real-time data access and remote monitoring. While it offers numerous benefits, including flexibility and operational efficiency, careful consideration of communication reliability is needed. Also, with power management, as it essential to maximize its performance. As technology continues to advance, wireless flow meters are likely to become increasingly prevalent. Furthermore, offering even greater capabilities and integration with digital and IoT systems.

Specifications

| Product Name |

Wireless Flow Meter Sensor |

| Pressure Range |

0 ~ 1500 GPM |

| Configuration method |

Local USB / remote configuration |

| Working power |

3.6V,19Ah |

| Battery Life |

5 years (send data every hour) |

| Power consumption |

Normal work 70mA sleep is less than 0.1mA, data sending and receiving 330mA |

| Display |

large size LCD screen |

| Network format |

NB-IOT/GPRS/4G/LoRa |

| Antenna |

External waterproof antenna |

| SIM Card |

Built-in SIM card |

| Sampling interval |

1 Time / Min |

| Wake-up mode |

Buttons, Timing, USB |

| Upload information |

Flow, Temperature, Signal, Battery Power |

| Working temperature |

-30℃~+70℃ (Medium does not crystallize) |

| Accuracy |

0.5 |

| Temperature influence |

0.015% F.S/℃ |

| Waterproof level |

General Duty / Explosion-Proof |

| Installation |

Vertical and horizontal installation |

| Certificate |

CE, RoHS, Ex d IIB T6 Gb |

Communication Options

LoRa (Long Range), NB-IoT (Narrowband IoT), and 4G are different wireless communication technologies, each with unique characteristics and use cases:

LoRa

- LoRa is a low-power, long-range wireless communication technology designed for connecting battery-operated devices over long distances.

- It operates in the unlicensed radio spectrum, offering long-range connectivity with minimal power consumption, making it suitable for Internet of Things (IoT) applications such as smart city infrastructure, agriculture, and industrial monitoring.

- LoRa is known for its ability to penetrate obstacles and provide reliable communication in challenging environments.

NB-IoT

- NB-IoT, or Narrowband IoT, is a Low Power Wide Area Network (LPWAN) technology designed for long-range, low-power IoT applications using licensed cellular bands.

- It provides deeper coverage compared to traditional cellular networks and is optimized for efficient data transmission from a large number of IoT devices.

- NB-IoT is well-suited for applications that require long battery life, such as asset tracking, smart meters, and remote monitoring.

4G

- 4G is a standard for wireless broadband communication, providing high-speed data transmission and low latency for mobile devices and applications.

- It operates in licensed bands and is commonly used for high-bandwidth applications, such as mobile internet access, video streaming, and voice communication.

- 4G offers fast and reliable data connectivity, making it suitable for applications that require real-time data transmission and high-speed internet access.

In summary, LoRa and NB-IoT are tailored for low-power, long-range IoT applications, with the former working in unlicensed spectrum and the latter leveraging licensed cellular bands. On the other hand, 4G provides high-speed, high-bandwidth communication for mobile and data-centric applications. The choice of technology depends on the specific requirements of the application, such as range, power consumption, and data transmission speed.

Installation

Installing a wireless flow meter involves several key steps to ensure accurate measurement and optimal performance. Here’s a detailed procedure to guide you through the installation process:

Planning and Preparation

Review Manufacturer’s Documentation: Begin by thoroughly reading the installation manual provided by the manufacturer. It contains specific instructions and requirements for your particular model.

Gather Necessary Tools and Equipment: Ensure you have all required tools, such as wrenches, pipe cutters, sealants, and any mounting hardware. Verify that you have the appropriate power sources or batteries if needed.

Select Installation Location: Choose an installation location that is accessible, allows for proper alignment, and provides adequate wireless signal strength. Avoid locations with excessive vibration, temperature extremes, or potential physical obstructions.

System Preparation

Shut Down and Drain the System: If the flow meter is being installed in a pipeline, ensure the system is shut down and completely drained to prevent spills and ensure safety.

Clean the Installation Area: Clean the pipe or mounting surface where the flow meter will be installed. Remove any debris, old gaskets, or rust that might interfere with the installation.

Installing the Flow Meter

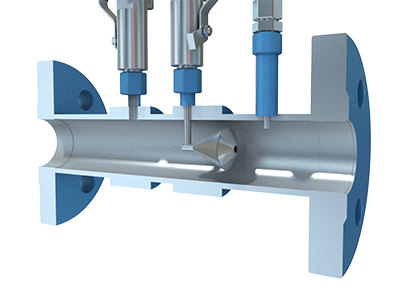

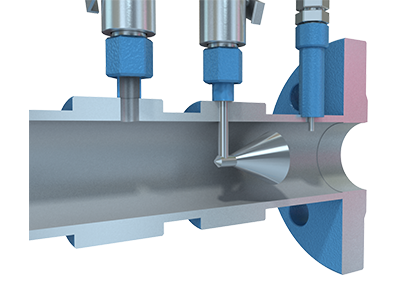

Prepare the Pipe or Mounting Surface: If installing an inline flow meter, ensure that the pipe is cut cleanly, and the ends are aligned. For external or clamp-on models, ensure the mounting surface is prepared according to the manufacturer’s guidelines.

Install the Flow Meter:

-

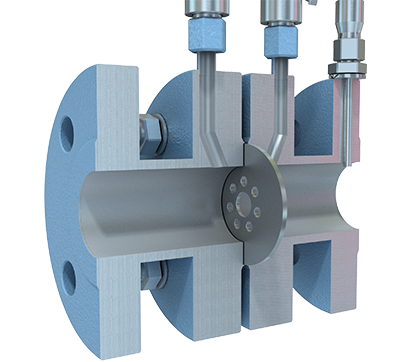

- Inline Flow Meter: Place the flow meter between the flanges or pipe sections. Ensure proper alignment with the bolt holes and install the provided gaskets.

- Clamp-on Flow Meter: Position the transducers or sensors on the exterior of the pipe according to the manufacturer’s instructions. Ensure the sensors are aligned correctly and securely fastened.

Secure the Flow Meter: Tighten the bolts or fasteners evenly to avoid any deformation or leakage. For clamp-on models, ensure that the clamps or brackets are firmly attached.

Wireless Communication Setup

Power the Flow Meter: Insert batteries or connect to the power source as specified by the manufacturer. If using energy harvesting technology, ensure the system is set up to capture the necessary energy.

Configure Wireless Settings: Follow the manufacturer’s instructions to configure the wireless communication settings. This may involve pairing the meter with a receiver, setting up network connections, or configuring communication protocols.

Test Wireless Connectivity: Verify that the flow meter is successfully transmitting data to the receiver or control system. Check for signal strength and ensure there are no obstructions or interference affecting communication.

Calibration and Testing

Calibrate the Flow Meter: Perform any required calibration procedures as outlined in the manufacturer’s documentation. This step is crucial for ensuring accurate measurements.

Conduct a Functional Test: Gradually reintroduce fluid or gas into the system and observe the flow meter’s readings. Check for accuracy, consistency, and any signs of leaks or malfunctions.

Verify Data Transmission: Ensure that data from the flow meter is being correctly transmitted and displayed on the receiver or monitoring system. Confirm that the data aligns with expected values.

Final Checks and Documentation

Inspect Installation: Perform a final inspection to ensure that all components are securely installed, there are no leaks, and the wireless communication is stable.

Document the Installation: Record installation details, including the location of the flow meter, configuration settings, calibration results, and any observations from the testing phase. This documentation will be useful for future reference and maintenance.

Provide Training: If necessary, provide training or instructions to relevant personnel on how to operate, monitor, and maintain the wireless flow meter.

Ongoing Maintenance and Monitoring

Schedule Regular Inspections: Plan regular inspections and maintenance activities to ensure continued accurate operation of the flow meter.

Monitor Performance: Continuously monitor the performance of the flow meter and wireless communication. Address any issues promptly to maintain reliable data measurement and transmission.

By following these installation procedures, you can ensure that your wireless flow meter is set up correctly, functions effectively, and provides accurate flow measurements for your system.

Maintenance

Maintaining a wireless flow meter is essential for ensuring its accuracy, reliability, and longevity. Here’s a detailed maintenance procedure to help you keep your wireless flow meter in optimal working condition:

Regular Inspections

- Visual Inspection: Perform regular visual checks of the flow meter to identify any signs of physical damage, such as cracks, corrosion, or wear. Inspect the housing, sensors, and mounting components.

- Wireless Signal Check: Ensure that the wireless communication between the flow meter and the receiver or control system is functioning correctly. Verify signal strength and connectivity to prevent data loss or inaccuracies.

- Leak Detection: For inline flow meters, check for leaks around the flanges or connections. Look for any signs of fluid escaping or unusual wet spots.

Cleaning

Schedule Cleaning: Depending on the type of fluid or gas being measured and the operating conditions, schedule cleaning at regular intervals to prevent build-up or contamination.

Cleaning Procedure:

- Shut Down System: Ensure that the system is turned off and the pressure is relieved before cleaning.

- Remove the Flow Meter: If necessary, carefully remove the flow meter from the pipeline or mounting surface.

- Clean the Sensor and Components: Use a non-abrasive cleaner and a soft cloth or sponge to clean the sensor and other exposed surfaces. Avoid harsh chemicals that could damage the components.

- Reinstall: After cleaning, reinstall the flow meter, ensuring that all connections are secure and correctly aligned.

Calibration

Perform Regular Calibration: Follow the manufacturer’s guidelines to perform calibration checks at recommended intervals. Calibration ensures that the flow meter provides accurate measurements.

Calibration Procedure:

- Verify Calibration Schedule: Check the manufacturer’s recommendations for calibration frequency.

- Use Calibration Standards: Use standard calibration fluids or gases to test the flow meter’s accuracy.

- Adjust Settings: If necessary, adjust the flow meter’s settings to align with the calibration standards.

Battery and Power Management

- Check Power Sources: Regularly inspect the battery or power source to ensure it is functioning correctly. For battery-powered models, monitor battery levels and replace them as needed.

- Energy Harvesting Systems: For meters with energy-harvesting systems, ensure that the energy source (e.g., solar panels) is clean and unobstructed to maintain efficient power generation.

- Power Connections: Verify that all power connections are secure and free from corrosion or damage.

Firmware and Software Updates

- Check for Updates: Periodically check for firmware or software updates from the manufacturer. Updates can provide bug fixes, performance improvements, or new features.

- Install Updates: Follow the manufacturer’s instructions to download and install any available updates. Ensure that updates are applied during scheduled maintenance periods to avoid disrupting operations.

Data Management

- Review Data Logs: Regularly review the data logs stored by the flow meter for any anomalies or trends that could indicate potential issues.

- Backup Data: Ensure that data is backed up as required, especially if the flow meter integrates with cloud-based platforms or data management systems.

Troubleshooting

- Address Performance Issues: If the flow meter exhibits irregular performance or inaccuracies, perform troubleshooting steps as outlined in the manufacturer’s manual. Common issues might include signal interference, calibration errors, or sensor malfunctions.

- Contact Support: For persistent issues or complex problems, contact the manufacturer’s technical support team for assistance.

Documentation

- Record Maintenance Activities: Document all maintenance activities, including inspections, cleaning, calibrations, and any repairs. This documentation helps track the history of the flow meter and plan future maintenance.

- Update Maintenance Logs: Keep detailed logs of any changes or updates made to the flow meter’s configuration, software, or hardware.

Training and Best Practices

- Train Personnel: Ensure that all personnel responsible for operating or maintaining the flow meter are properly trained and familiar with its operation and maintenance procedures.

- Follow Best Practices: Adhere to industry best practices for the care and handling of flow meters, including avoiding exposure to harsh environments or chemicals that could damage the equipment.

By following these maintenance procedures, you can help ensure that your wireless flow meter operates efficiently, provides accurate measurements, and remains in good working condition over its lifespan. Regular maintenance not only extends the life of the equipment but also contributes to reliable and consistent performance.

Q&A

A Q&A Wireless Flow Meter, which stands for “question and answer for a Wireless Flow Meter,” is a format commonly used to facilitate communication and exchange of information. In a Q&A Wireless Flow Meters, one person asks a question, and another person or group provides an answer or response to that question. This format is widely used in various contexts, such as interviews, discussions, presentations, or online forums. It allows for a structured and organized way of addressing inquiries and obtaining relevant information. Is there anything specific you would like to know about Q&A Wireless Flow Meters?

Q: What is a wireless flow meter?

A: A wireless meter is a type of flow meter that transmits data wirelessly to a remote location. The meter uses sensors to measure the flow of fluid in a pipeline or other system. After that, it sends the data to a receiver or other device using wireless technology such as Bluetooth or Wi-Fi.

Q: What are the benefits of using wireless flow meters?

A: The benefits of using wireless flow meters include increased convenience, flexibility, and accuracy. Wireless meters eliminate the need for complex wiring and can be installed in remote or hard-to-reach locations. They can also be easily moved or repositioned as needed. Additionally, wireless meters can provide real-time data that can be used to monitor system performance. This will also identify potential issues before they become major problems.

Q: What types of fluids can be measured with Q&A Wireless Flow Meters?

A: Wireless meters can be used to measure a wide range of fluids, including liquids and gases. Some meters are designed specifically for use with certain types of fluids. Others are more versatile and can be used with a variety of fluids.

Q: How accurate are wireless meters?

A: The accuracy of wireless flow meters varies depending on factors such as the type of meter, the fluid being measured, and the conditions in which the meter is used. In general, wireless flow meters are highly accurate and can provide precise measurements even in challenging environments.

Q: What is the range of a wireless meter?

A: The range of a wireless meter depends on the specific technology used and the environment in which the meter is used. Some meters have a range of just a few feet, while others can transmit data over long distances. In general, the range of a wireless meter can be extended by using repeaters or other signal boosters.

Q: What is the installation process for a wireless meter?

A: The installation process for a wireless flow meter varies depending on the specific meter and the system being measured. In general, the meter must be placed in a location where it can accurately measure the flow of fluid. After that, it is connected to the wireless network using the appropriate technology. Some wireless meters are designed to be easy to install and can be set up in just a few minutes. Many other types may require more extensive installation and configuration.

Q: Can wireless meters be integrated with other systems?

A: Yes, wireless flow meters can be integrated with other systems, such as SCADA (Supervisory Control and Data Acquisition) systems or building automation systems. The integration allows for real-time monitoring and control of the flow of fluids in a system. This can also help to improve efficiency and reduce waste.

Q: Are wireless meters more expensive than wired meters?

A: Wireless meters can be more expensive than wired meters due to the additional technology required for wireless communication. However, the cost of wireless meters has decreased over time as the technology has become more widespread and affordable. In some cases, the cost of wireless meters may be offset by the savings in installation costs compared to wired meters.

Q: What is the maintenance required for Q&A Wireless Flow Meters?

A: The maintenance required for wireless flow meters depends on the specific meter and the environment in which it is used. In general, wireless meters require less maintenance than wired meters. This is due to the lack of wiring and connections that can degrade over time. However, regular calibration and cleaning of the meter may be necessary to ensure accurate measurements.

Q: What are the security risks associated with wireless meters?

A: Wireless meters can be vulnerable to hacking or other security threats if they are not properly secured. To mitigate these risks, wireless meters should be encrypted and secured with strong passwords. Additionally, it is important to regularly update the firmware and software used with the meter. This is to ensure that any security vulnerabilities are addressed.

Q: Can flow meters be used in hazardous environments?

A: Yes, wireless flow meters can be used in hazardous environments as long as they are designed and certified for use in such environments. In these cases, the meters may need to meet specific safety standards. Many of these meters are designed to operate in environments with potentially explosive gases or other hazardous materials.

Buy Wireless Flow Meters

Advantages / Disadvantages

Advantages of a Wireless Flow Meter

One of the primary advantages of wireless flow meters is their ability to provide accurate and reliable measurements across different operating conditions. Unlike traditional flow meters, wireless meters allow for continuous monitoring, enabling users to detect any abnormalities or variations in flow rates promptly. This real-time data provides valuable insights for process optimization, maintenance scheduling, and troubleshooting.

Another benefit of wireless flow meters is their remote monitoring capability. As the data is transmitted wirelessly, users can access the information from a central control room, a computer, or even a mobile device, thus ensuring the accessibility of the data at all times. This remote monitoring feature allows for efficient data management, enabling timely decision-making and reducing the need for on-site visits and manual data retrieval.

The wireless nature of these flow meters also contributes to improved safety in industrial settings. With no physical connections, there is a lower risk of leaks, corrosion, or accidents caused by damaged cables. Additionally, wireless meters eliminate the need for workers to access hazardous areas for data retrieval, reducing potential employee exposure to dangerous environments.

Realize the remote real-time monitoring, wireless transmission, no need site wiring, saves on the ordinary instrument field wiring required. It will save manpower and construction costs. The instrument is advanced in design, has complete specifications, and is easy to install and use. This is the ideal upgrade product for a traditional pressure transmitter. The Wireless Flow Meter is the revolutionary innovation of the traditional differential pressure flow meter system.

Also, wireless products are the future technology of industrial control systems. Physical wiring was used in the past and will always be used on higher power-required applications. Wireless on Temperature, Pressure, Level, and flow are low-power applications and easily converted to wireless signals.

Easy Installation: Wireless flow meters are typically easier to install compared to wired counterparts since there is no need for extensive wiring, conduits, or cables.

Remote Monitoring: Wireless flow meters allow for convenient remote monitoring of flow data, enabling real-time insights and adjustments from a distance.

Cost-Effective: In some cases, wireless flow meters can be more cost-effective to install and maintain, especially in scenarios where wiring can be expensive or challenging.

Scalability: Wireless systems are often easier to expand or modify, allowing for scalability as monitoring needs evolve or new measurement points are added.

Reduced Downtime: Wireless flow meters can help reduce downtime during installation or maintenance, as they can be easily relocated or replaced without disrupting existing infrastructure.

Disadvantages of a Wireless Flow Meter

Signal Interference: Wireless flow meters may be susceptible to signal interference from other wireless devices or environmental factors, which can impact data accuracy or transmission reliability.

Power Requirements: Some wireless flow meters require power sources like batteries or charging, which may need to be regularly maintained or replaced.

Data Security: Wireless transmission of flow data may pose security concerns, as data could be vulnerable to interception or unauthorized access without proper encryption measures.

Limited Range: Depending on the wireless technology used, there may be limitations to the range over which data can be reliably transmitted, especially in large or complex environments.

Compatibility Issues: Compatibility with existing systems or protocols may be a challenge when integrating wireless flow meters into an existing monitoring infrastructure, requiring additional configuration or adapters.

These advantages and disadvantages can vary depending on the specific wireless flow meter technology, application, and environmental factors. It’s essential to consider these factors when choosing a wireless flow meter for a particular use case.

Applications

Industries and Applications

Wireless flow meters are highly versatile and can be utilized in a wide range of industries and applications. They find applications in sectors such as oil and gas, water and wastewater management, chemical processing, pharmaceuticals, food and beverage, HVAC (heating, ventilation, and air conditioning), and many more. In these industries, wireless flow meters are essential for monitoring and controlling flow rates, ensuring optimal efficiency and compliance with regulatory standards.

Oil and Gas

In the oil and gas industry, for example, wireless flow meters are used for measuring the flow of crude oil, natural gas, refined products, and various chemicals. These measurements are crucial for production optimization, custody transfer, and leakage detection. With their wireless capabilities, these meters enable real-time monitoring across vast oil fields, ensuring early detection and mitigation of issues that could potentially impact operations.

Water and Wastewater

Water and wastewater management is another application where wireless flow meters play a vital role. These meters allow for continuous monitoring of water flow within pipelines, reservoirs, and treatment plants. This data helps in identifying leakage points, minimizing water loss, and optimizing the distribution networks. Similarly, in the food and beverage industry, wireless flow meters assist in maintaining accurate flow measurements during processes such as mixing, blending, and bottling, ensuring product consistency and quality.

In conclusion, the wireless flow meter offers numerous advantages over traditional meters by providing accurate, real-time flow measurements, remote monitoring capabilities, and enhanced safety. Their versatility makes them suitable for a wide range of applications across various industries. With continuous advancements in wireless technology, these meters are poised to revolutionize the way flow measurements are conducted, helping industries optimize processes, reduce costs, and improve overall efficiency.

Downloads

Drawings