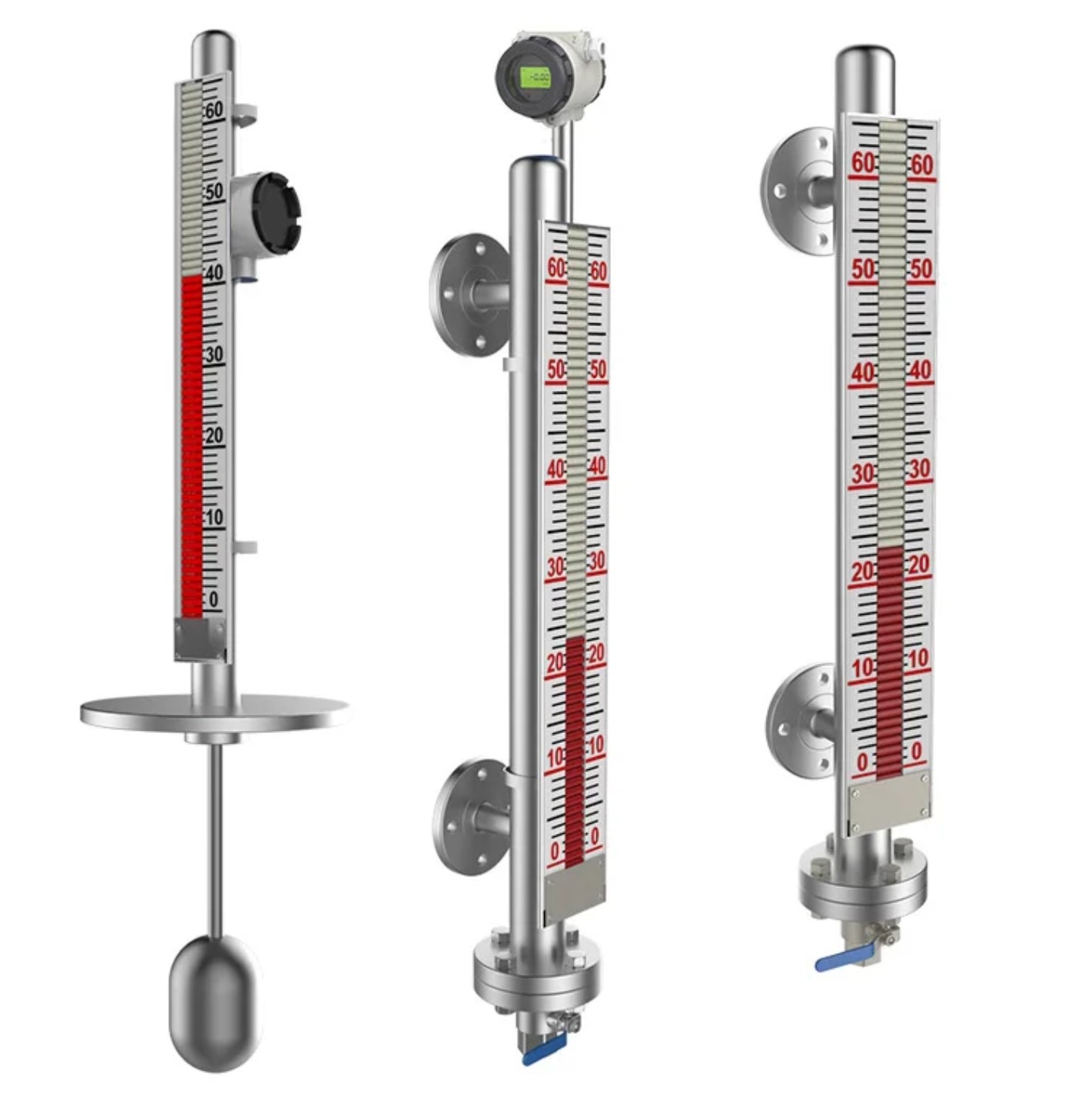

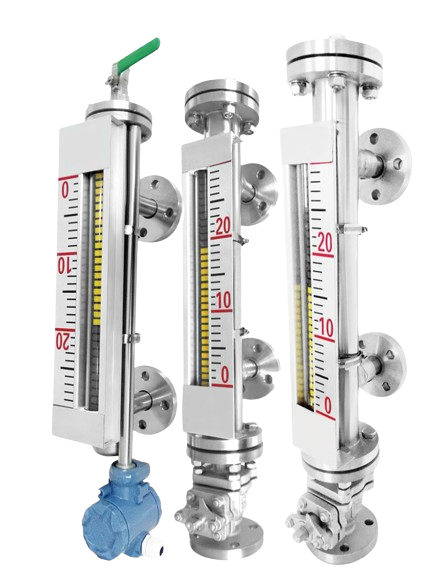

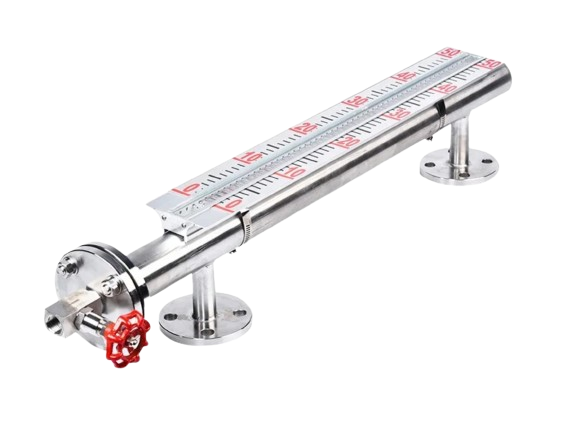

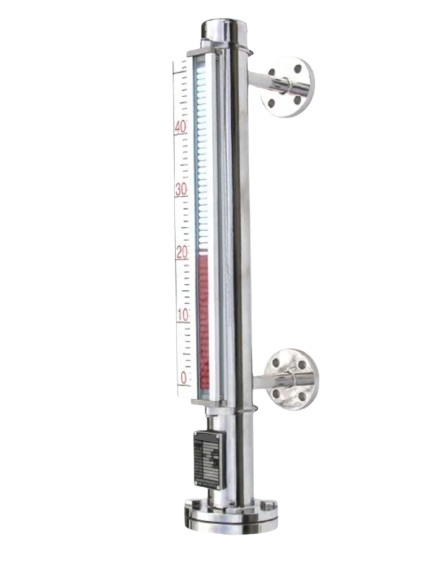

Magnetic Level Gauge

$ 678.00 – $ 2,841.00Price range: $ 678.00 through $ 2,841.00

A Magnetic Level Gauge is a precision instrument used for measuring liquid levels in industrial applications. It employs magnetic principles to provide accurate and reliable level readings. The gauge consists of a float with a permanent magnet that moves along a guide tube based on the liquid level, with external sensors detecting changes in the magnetic field. This information is then converted into an electrical signal for monitoring and control systems, making it an essential tool for various industries requiring precise liquid level measurements.

Description

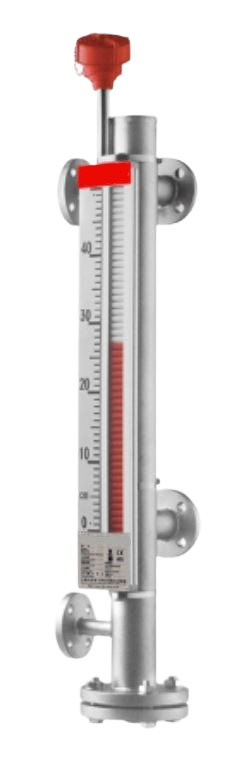

The Magnetic Level Gauge is a sophisticated instrument designed to accurately measure liquid levels in various industrial applications. It utilizes the principles of magnetic coupling and fluid dynamics to provide precise and reliable level measurements. People recognize this device for its durability, high accuracy, and suitability for harsh environments. Environments such as those requiring explosion-proof and corrosion-resistant features.

The Magnetic Level Gauge is a sophisticated instrument designed to accurately measure liquid levels in various industrial applications. It utilizes the principles of magnetic coupling and fluid dynamics to provide precise and reliable level measurements. People recognize this device for its durability, high accuracy, and suitability for harsh environments. Environments such as those requiring explosion-proof and corrosion-resistant features.

At the heart of the Magnetic Level Gauge is a float containing a permanent magnet. A magnet that moves freely along a guide tube. The float’s movement is directly influenced by the liquid level in the tank, causing the magnetic field to change accordingly. A series of magnetic sensors placed outside the guide tube detects this change. These sensors convert the magnetic field variation into an electrical signal.

Features of a Magnetic Level Gauge

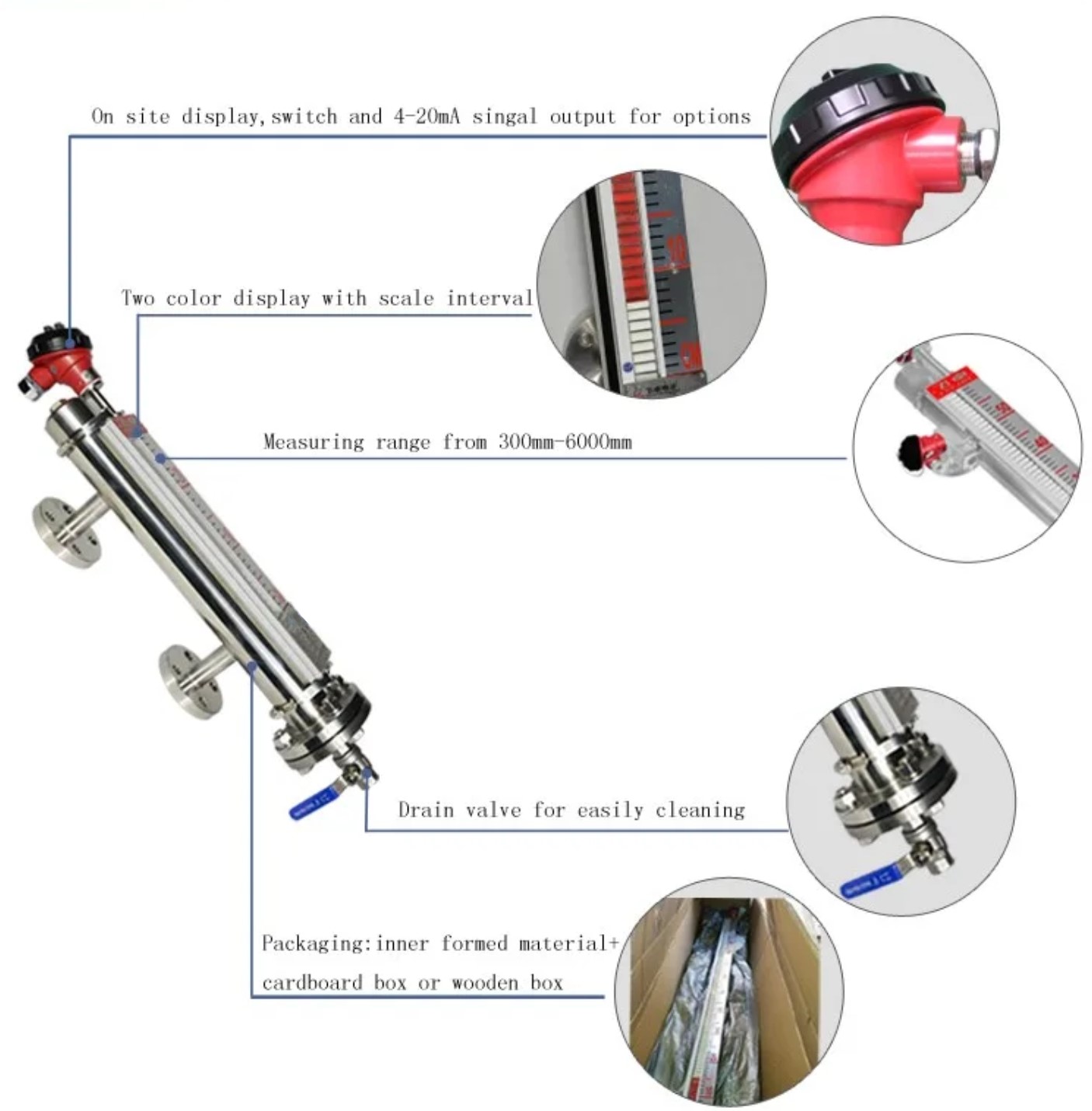

One of the key features of the Magnetic Level Gauge is its 4-20mA output signal. This signal which is a standard in industrial instrumentation for transmitting analog signals. This output signal allows for easy integration with control systems and PLCs. This allows real-time monitoring and control of the liquid level. The 4-20mA signal provides a linear representation of the liquid level. This means a 4mA typically corresponding to the empty tank condition and 20mA to the full tank condition.

In industrial environments where safety is paramount, explosion-proof design is crucial. Manufacturers often construct the Magnetic Level Gauge with explosion-proof materials and housings. Additionally, these constructions prevent the risk of ignition in hazardous areas. Finally, this ensures that the instrument can safely operate in environments with flammable gases or vapors, meeting strict safety standards and regulations.

Corrosion Resistance

The Magnetic Level Gauge offers excellent corrosion resistance, which is especially crucial in industries that handle harsh chemicals or corrosive liquids. Also, the construction team carefully selects the materials to withstand corrosion over extended periods, ensuring the long-term reliability and accuracy of level measurements. In addition, engineers often employ special coatings, such as PTFE or stainless steel, to protect the instrument from the corrosive effects of the process fluid.

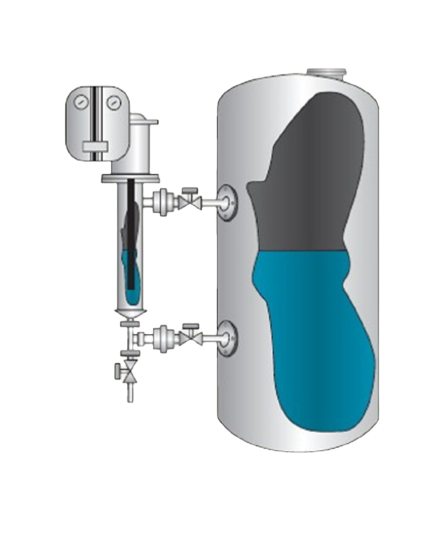

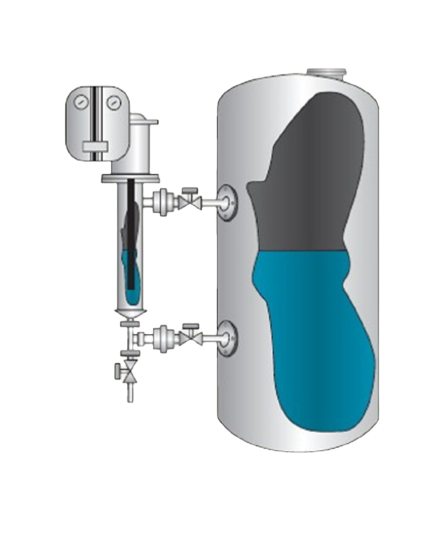

The installation of the Magnetic Level Gauge is straightforward, with the guide tube mounted vertically on the side of the tank. Furthermore, the float inside the guide tube moves freely with the liquid level, allowing for continuous, non-contact level measurement. Finally, the instrument requires minimal maintenance and calibration, making it a cost-effective solution for level monitoring in various industrial applications.

Overall, the sensor with 4-20mA output, explosion-proof, and corrosion-resistant features is a versatile and dependable liquid-level measurement instrument in challenging industrial environments. In addition, it’s combination of advanced technology, robust design, and safety features makes it an ideal choice for applications where accuracy, reliability, and safety are paramount.

You may be interested in other Level Transmitters.

Radar Level Transmitter

Ultrasonic Level Transmitter

Specifications

| Measuring Range |

10″ to (250mm~6000mm even longer, over 4 meters can be segmented, |

| Installation Method |

Side-mounted; Top-mounted type |

| Medium Temperature |

PP:0~50℃; UPVC:0~50℃.

Stainless steel:-40~380℃

|

| Body Material |

304 stainless steel; 316L stainless steel; PP; UPVC; Stainless steel lined with PTFE |

| Pressure Class |

1.0Mpa; 1.6Mpa; 2.5Mpa; 4.0Mpa; 6.3Mpa; 10Mpa; 16Mpa |

| Installation Flange |

1/2″, 3/4″, 1″, 1-1/2″, 2″ (DN20 PN16; DN25 PN16; DN80 PN10) |

| Medium Density |

≥0.7g/cm³ (Side-mounted);

≥0.8g/cm³ (Top -mounted)

|

| Remote Transmission |

4-20Ma / 4-20Ma + HART |

| Accuracy |

±10mm |

Model Selection

| HL-UHZ |

25 |

|

Side-mounted |

Measurement Type |

|

26 |

|

Bottom mounted |

| 27 |

|

Top -mounted |

| 28 |

|

Side and top-mounted |

| 29 |

|

Side and Bottom-mounted |

|

1 |

|

Double-sided panel |

Display Mode |

| 2 |

|

Single sided panel |

| 3 |

|

Single band luminous type |

| 4 |

|

LED display type |

| LB |

Normal bundled remote transmission(4-20Ma) |

Remote Transmitter |

| GLB |

High-temperature bundled remote transmission(4-20 Ma) |

|

O |

Normal type |

Explosion-proof Class |

|

G |

Flameproof type |

|

|

XM6 |

Equipped with remote transmission digital display meter |

Remote Display |

|

|

|

| A |

|

1Cr18Ni9Ti(321) |

| B |

|

OCr18Ni9(304) |

| C |

|

316、316L |

| D |

|

RPP |

| E |

|

Titanium alloy |

| F |

|

304 lined with PTFE |

| 10 |

≤1.0MPa |

Working Pressure |

| 16 |

≤1.6MPa |

| 25 |

≤2.5MPa |

| 40 |

≤4.0MPa |

| 64 |

≤6.4MPa |

| 100 |

≤10.0MPa |

|

≤OTHER |

|

A |

≤60℃ |

Working temperature |

|

B |

≤100℃ |

|

C |

≤120℃ |

|

D |

≤180℃ |

|

E |

≤250℃ |

|

F |

≤350℃ |

|

G |

≤450℃ |

|

|

≤OTHER |

| 口口口口 |

Measuring range and installation center distance mm) |

Distance Between Centers |

|

A |

DN20(Suitable for side mounting) |

Mounting flange |

|

B |

DN25(Suitable for side mounting) |

|

C |

DN32(Suitable for side mounting) |

|

|

DN40 (Suitable for side mounting) |

|

D |

DN50(Suitable for side mounting) |

|

E |

DN80(Suitable for top mounting) |

|

F |

DN100(Suitable for top mounting) |

|

G |

DN150(Suitable for top mounting) |

|

H |

DN200(Suitable for top mounting) |

|

|

DN250 (Suitable for top mounting) |

| V |

Vacuum jacketed type |

Special Requirements |

| W |

Steam jacketed type |

| X |

Electric heat tracing type |

| Z |

User-specified special type |

Installation

Installing a Magnetic Level Gauge requires careful planning and attention to detail to ensure accurate and reliable level measurements. Here are the general installation procedures for a Magnetic Level Gauge:

Preparation:

- Identify the mounting location on the side of the tank where the guide tube will be installed vertically.

- Ensure the area is clear of obstructions and accessible for installation and maintenance.

Mounting the Guide Tube:

- Securely mount the guide tube on the tank using appropriate brackets or mounting hardware.

- Verify that the guide tube is vertical and aligned correctly for accurate level measurements.

Installing the Float:

- Insert the float into the guide tube and ensure it moves freely without any obstructions.

- Check for proper alignment and functioning of the float inside the guide tube.

Connecting the Electrical Wiring:

- Connect the output signal wires of the Magnetic Level Gauge to the control system or monitoring device as per the manufacturer’s instructions.

- Ensure proper grounding and protection of electrical connections to prevent interference or damage.

Calibration and Testing:

- Follow the calibration procedures provided by the manufacturer to set the reference points for empty and full tank conditions.

- Test the Magnetic Level Gauge by filling the tank with the liquid and verifying the accuracy of the level readings.

Seal and Secure:

- Seal all connections and openings to prevent leakage or ingress of foreign materials.

- Secure all fasteners and brackets to ensure the stability and integrity of the installation.

Verification and Adjustments:

- Verify the accuracy of the level measurements under different operating conditions and adjust as necessary.

- Ensure that the Magnetic Level Gauge operates smoothly and provides consistent readings over time.

Documentation and Maintenance:

- Keep detailed records of the installation, calibration, and maintenance activities for future reference.

- Establish a regular maintenance schedule to ensure the continued accuracy and reliability of the Magnetic Level Gauge.

By following these installation procedures carefully and adhering to manufacturer guidelines, you can ensure the successful integration of the Magnetic Level Gauge into your industrial process for accurate liquid level measurements.

Advantages / Disadvantages

Advantages of Magnetic Level Gauges

Accuracy: Magnetic Level Gauges provide precise and reliable liquid level measurements, making them suitable for critical industrial processes.

Non-contact measurement: The float inside the guide tube moves without direct contact with the liquid, reducing the risk of contamination and maintenance requirements.

Easy integration: With a 4-20mA output signal, Magnetic Level Gauges can be easily integrated into control systems and automation processes for seamless monitoring and control.

Durability: Designed with corrosion-resistant materials, these gauges are durable and suitable for harsh environments, ensuring long-term reliability.

5. Safety: The explosion-proof design of Magnetic Level Gauges makes them safe to use in hazardous areas with flammable substances, meeting strict safety regulations.

Disadvantages of Magnetic Level Gauges

Cost: Magnetic Level Gauges can be more expensive upfront compared to some other types of level measurement instruments.

Installation complexity: While the installation process is usually straightforward, the initial setup may require some expertise and time.

Maintenance: Although Magnetic Level Gauges generally require minimal maintenance, any malfunctions or damage may require specialized attention for repairs.

External factors: External magnetic fields or interference can sometimes affect the accuracy of the level readings, requiring additional mitigation measures.

Limited to liquid measurement: Magnetic Level Gauges are primarily designed for measuring liquid levels and may not be suitable for other types of substances or applications.

Q&A

Q: What is a Magnetic Level Gauge?

A: A Magnetic Level Gauge is an instrument used for accurately measuring liquid levels in industrial applications. It utilizes magnetic principles to provide precise and reliable level measurements.

Q: How does a Magnetic Level Gauge work?

A: The Magnetic Level Gauge consists of a float with a permanent magnet that moves along a guide tube based on the liquid level. External sensors detect the magnetic field changes, converting them into an electrical signal for level indication.

Q: What is the significance of the 4-20mA output in a Magnetic Level Gauge?

A: The 4-20mA output signal in a Magnetic Level Gauge is a standard means of transmitting analog signals in industrial instrumentation. It offers a linear representation of liquid levels for seamless integration with control systems.

Q: Why is explosion-proof design important in industrial instruments like the Magnetic Level Gauge?

A: Explosion-proof design is crucial in hazardous environments where flammable gases or vapors are present. It ensures the safety of operations by preventing the risk of ignition and meeting strict safety standards.

Q: How does the corrosion-resistant feature benefit a Magnetic Level Gauge?

A: Corrosion resistance is essential in environments with harsh chemicals or corrosive liquids. It protects the instrument from degradation, ensuring long-term reliability and accurate level measurements.

Q: What are some common applications of Magnetic Level Gauges?

A: Magnetic Level Gauges are used in industries such as oil and gas, chemical processing, power generation, and wastewater treatment for monitoring liquid levels in tanks and vessels accurately.

Applications

Magnetic Level Gauges are versatile instruments suitable for various industrial applications where precise and reliable liquid level measurement is essential. Some common applications include:

Oil and Gas Industry: Magnetic Level Gauges are used in oil refineries, storage tanks, and processing facilities for monitoring oil levels accurately.

Chemical Processing: These gauges are employed in chemical plants to measure levels of corrosive liquids safely and reliably.

Petrochemical Industry: Magnetic Level Gauges find application in petrochemical plants for monitoring liquid levels in storage tanks and reactors.

Power Generation: Power plants use Magnetic Level Gauges to measure water levels in boilers, cooling towers, and condensers.

Food and Beverage: In food processing facilities, these gauges are used to monitor liquid levels in tanks and vessels containing ingredients or final products.

Pharmaceuticals: Magnetic Level Gauges are utilized in pharmaceutical manufacturing for precise level measurements of liquids in storage tanks and reactors.

Wastewater Treatment: These gauges help monitor liquid levels in sewage treatment plants and wastewater storage tanks.

Aerospace and Automotive: Magnetic Level Gauges are used in aviation and automotive industries for monitoring fuel levels accurately.

Biotechnology: In biotech laboratories, these gauges are employed for measuring liquid levels in bioreactors and fermentation tanks.

Marine and Shipping: Magnetic Level Gauges find application in cargo ships and vessels for monitoring fluid levels in various tanks, including fuel and ballast tanks.

Downloads

Drawings

The Magnetic Level Gauge is a sophisticated instrument designed to accurately measure liquid levels in various industrial applications. It utilizes the principles of magnetic coupling and fluid dynamics to provide precise and reliable level measurements. People recognize this device for its durability, high accuracy, and suitability for harsh environments. Environments such as those requiring explosion-proof and corrosion-resistant features.

The Magnetic Level Gauge is a sophisticated instrument designed to accurately measure liquid levels in various industrial applications. It utilizes the principles of magnetic coupling and fluid dynamics to provide precise and reliable level measurements. People recognize this device for its durability, high accuracy, and suitability for harsh environments. Environments such as those requiring explosion-proof and corrosion-resistant features.