Description

A wireless temperature transmitter is a device designed to measure temperature and wirelessly transmit this data to a central monitoring system or receiver. Also, these transmitters play a crucial role in various industries where monitoring and maintaining temperature levels is critical for operational efficiency, safety, and quality control.

A wireless temperature transmitter is a device designed to measure temperature and wirelessly transmit this data to a central monitoring system or receiver. Also, these transmitters play a crucial role in various industries where monitoring and maintaining temperature levels is critical for operational efficiency, safety, and quality control.

Here is a detailed breakdown of the components and functionality of a typical wireless temperature transmitter:

Sensor

A wireless temperature transmitter includes a sensor that detects temperature changes and converts them into electrical signals. In addition, common types of temperature sensors used include thermocouples, resistance temperature detectors (RTDs), and thermistors. Finally, the selection of the sensor type depends on factors like temperature range, accuracy, and environmental conditions.

Transmitter Unit

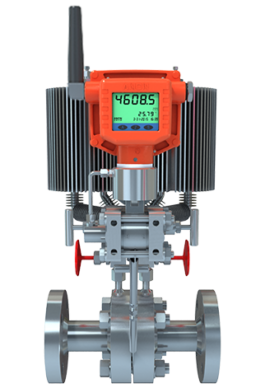

The transmitter unit processes the electrical signals from the sensor and transmits the data wirelessly to a receiver. It may include components such as a microprocessor, signal conditioning circuitry, and a radio frequency (RF) transmitter for wireless communication.

Wireless Communication

Wireless temperature transmitters utilize technologies like Bluetooth, Wi-Fi, Zigbee, or other proprietary wireless protocols to transmit temperature data. Moreover, this wireless connectivity eliminates the need for physical connections like cables, allowing for flexible installation and remote monitoring capabilities.

Power Source

Depending on the application and location of the transmitter, power is supplied through various means. Additionally, some transmitters use batteries, while others power them through energy harvesting systems, solar panels, or wired power sources.

Enclosures house the transmitter unit, protecting the internal components from environmental factors like dust, moisture, and temperature extremes. Manufacturers typically make enclosures out of materials like plastic, stainless steel, or aluminum based on the application requirements.

Installation and Calibration

Companies strategically install wireless temperature transmitters in crucial locations where temperature monitoring is essential. Proper calibration is essential to ensure accurate temperature readings, and some transmitters may support local or remote calibration capabilities.

Data Logging and Monitoring

A central monitoring system or receiver receives the temperature data transmitted wirelessly by the transmitter. This system collects, logs, and displays temperature information in real time. This allows operators to track temperature trends. Also, it sets alarm thresholds and makes informed decisions based on the data.

Wireless temperature transmitters find applications in various industries, including manufacturing, pharmaceuticals, food and beverage, HVAC, energy, and environmental monitoring. Furthermore, industries use them to monitor temperature in refrigeration units, industrial processes, storage facilities, laboratories, and more.

In summary, a wireless temperature transmitter is a sophisticated yet essential device that enables real-time temperature monitoring and data transmission without the constraints of wired connections. Finally, its versatility, accuracy, and remote monitoring capabilities make it a valuable tool. This tool allows for maintaining optimal temperature conditions in diverse industrial settings.

Specifications

- Input: Single sensor capability with universal sensor inputs (RTD, T/C, mV, ohms)

- Output Signal: Wireless HART / Zigbee protocol

- Housing: Dual-compartment field mount

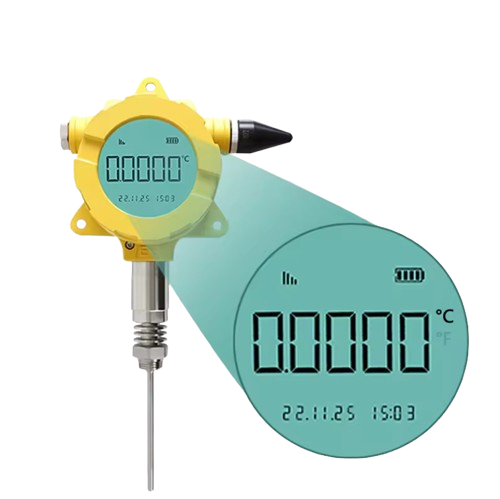

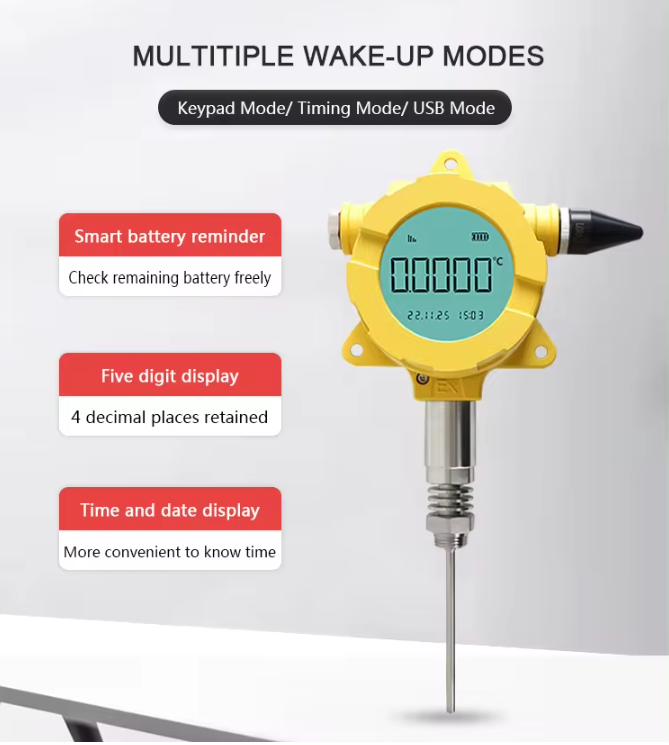

- Display/Interface: Large LCD with percent range graph

- Diagnostics: Basic diagnostics including open/short sensor diagnostics

- Calibration Options: Transmitter-sensor matching

- Certifications/Approvals: Hazardous location, marine type, see full specs for a complete list of certifications

- Update Rate: 1 sec. to 60 min., user selectable

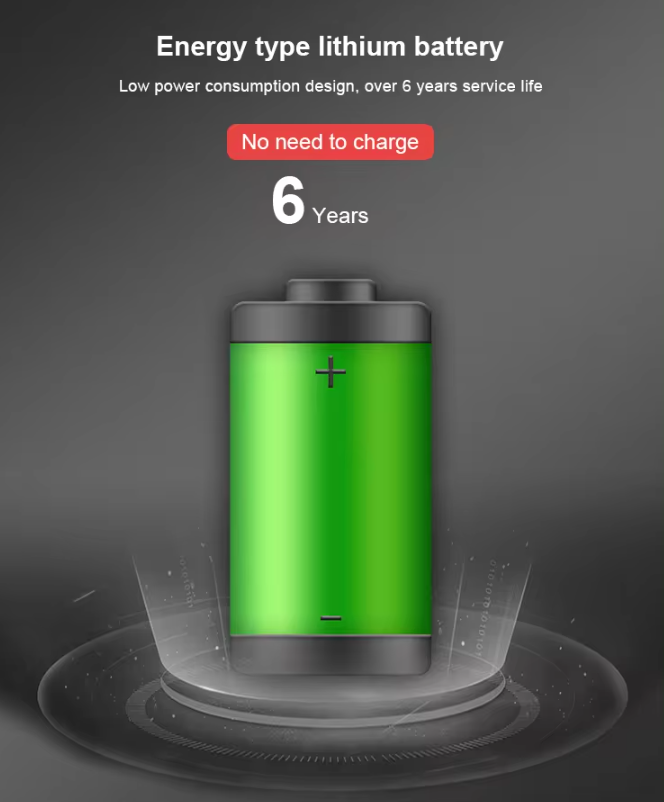

- Power Module Life: Up to 10-year life, field replaceable (order separately) Antenna Type: External (standard and extended range)

-

Wireless Temperature Transmitter HART / Zigbee technology is secure, cost-effective, and delivers >99% data reliability

- Best-in-class wireless accuracy and stability for process automation Durable dual-compartment housing offers added field reliability The technology measures temperature without a process penetration for reduced design, installation, and maintenance costs Wireless Temperature Transmitter sensor matching produces better accuracy, matching exact sensor characteristics with the transmitter LCD offers access to measurement and diagnostic information in the field, enhancing process visibility. The internal module provides up to 5-year maintenance-free operation and field replacement without transmitter removal Easy installation enables quick instrumentation of measurement points without the cost of wiring

Communication Options

LoRa (Long Range), NB-IoT (Narrowband IoT), and 4G are different wireless communication technologies, each with unique characteristics and use cases:

LoRa

- LoRa is a low-power, long-range wireless communication technology designed for connecting battery-operated devices over long distances.

- It operates in the unlicensed radio spectrum, offering long-range connectivity with minimal power consumption, making it suitable for Internet of Things (IoT) applications such as smart city infrastructure, agriculture, and industrial monitoring.

- LoRa is known for its ability to penetrate obstacles and provide reliable communication in challenging environments.

NB-IoT

- NB-IoT, or Narrowband IoT, is a Low Power Wide Area Network (LPWAN) technology designed for long-range, low-power IoT applications using licensed cellular bands.

- It provides deeper coverage compared to traditional cellular networks and is optimized for efficient data transmission from a large number of IoT devices.

- NB-IoT is well-suited for applications that require long battery life, such as asset tracking, smart meters, and remote monitoring.

4G

- 4G is a standard for wireless broadband communication, providing high-speed data transmission and low latency for mobile devices and applications.

- It operates in licensed bands and is commonly used for high-bandwidth applications, such as mobile internet access, video streaming, and voice communication.

- 4G offers fast and reliable data connectivity, making it suitable for applications that require real-time data transmission and high-speed internet access.

In summary, LoRa and NB-IoT are tailored for low-power, long-range IoT applications, with the former working in unlicensed spectrum and the latter leveraging licensed cellular bands. On the other hand, 4G provides high-speed, high-bandwidth communication for mobile and data-centric applications. The choice of technology depends on the specific requirements of the application, such as range, power consumption, and data transmission speed.

Installation

Installing a wireless temperature transmitter involves several steps to ensure accurate temperature measurements and reliable wireless communication. Here is a detailed guide to the installation procedure:

Planning and Preparation

Review Manufacturer’s Documentation: Start by carefully reading the installation manual provided by the manufacturer. This manual will include specific instructions, installation requirements, and safety precautions relevant to your model.

Gather Tools and Equipment: Collect all necessary tools and materials, including wrenches, mounting brackets, sealants, power sources or batteries, and any other components required for installation.

Select Installation Location: Choose an installation site that ensures accurate temperature readings and optimal wireless signal strength. The location should be accessible, free from excessive vibration, and protected from extreme environmental conditions.

System Preparation

Power Down the System: If the temperature transmitter is being installed in an active system, turn off the system and ensure it is at a safe temperature before installation to avoid accidents and ensure safety.

Prepare the Installation Surface: Clean the surface or pipe where the transmitter will be installed. Remove any debris, rust, or old sealant to ensure a good connection and accurate readings.

Installing the Temperature Transmitter

Prepare the Connection Point (Pipe or Surface Mount): For pipe or surface mounting, ensure that the area is clean and properly prepared according to the transmitter’s specifications. If installing on a pipe, ensure it is of the appropriate diameter and material compatible with the transmitter.

Install the Temperature Transmitter:

Direct Mounting: For transmitters designed to be mounted directly on a surface or pipe, use the provided mounting hardware to secure the transmitter. Ensure the transmitter is positioned in such a way that it accurately measures the temperature of the desired area.

Probe Installation: If the transmitter uses a probe, insert the probe into the designated port or mounting point. Secure it according to the manufacturer’s instructions to ensure proper thermal contact and accuracy.

Ensure Proper Alignment: Make sure the transmitter is correctly aligned and securely mounted to avoid mechanical stress or damage. For probe installations, ensure the probe is fully inserted and properly positioned.

Wireless Communication Setup

Power the Transmitter: Insert the batteries or connect the power source as specified by the manufacturer. Ensure that the power supply meets the transmitter’s requirements and is stable.

Configure Wireless Settings: Follow the manufacturer’s instructions to set up the wireless communication. This may include pairing the transmitter with a receiver or control system, configuring network settings, and establishing communication protocols.

Test Wireless Connectivity: Verify that the transmitter is successfully communicating with the receiver or monitoring system. Check for adequate signal strength and ensure there are no sources of interference.

Calibration and Testing

Calibrate the Transmitter: Perform calibration procedures as outlined in the manufacturer’s documentation. Calibration ensures the transmitter provides accurate temperature readings.

Conduct Functional Tests: Test the transmitter by exposing it to known temperature conditions. Verify that it accurately reads and transmits temperature data.

Verify Data Transmission: Ensure that the temperature data from the transmitter is correctly transmitted to and displayed by the receiver or monitoring system. Confirm that the data aligns with expected values.

Final Checks and Documentation

Inspect the Installation: Perform a final inspection to ensure that the transmitter is securely installed, there are no leaks or loose connections, and the wireless communication is stable.

Document the Installation: Record all relevant installation details, including the transmitter’s location, configuration settings, calibration results, and any observations from the testing phase. This documentation will be useful for future reference and maintenance.

Provide Training: If necessary, provide training or instructions to relevant personnel on operating, monitoring, and maintaining the wireless temperature transmitter.

Ongoing Maintenance and Monitoring

Schedule Regular Inspections: Plan and perform regular inspections to ensure the transmitter remains in good working condition. Check for signs of wear, damage, or calibration drift.

Monitor Performance: Continuously monitor the transmitter’s performance and wireless communication. Address any issues promptly to maintain accurate temperature measurements and reliable data transmission.

By following these installation procedures, you can ensure that your wireless temperature transmitter is set up correctly, functions effectively, and provides accurate temperature measurements. Regular maintenance and monitoring will help maintain its performance and extend its operational life.

Maintenance

Maintaining a wireless temperature transmitter is crucial for ensuring it provides accurate temperature measurements and operates reliably over time. Here’s a detailed guide to the maintenance procedures:

Routine Inspections

Visual Inspection: Conduct regular visual checks to identify any signs of physical damage, such as cracks, corrosion, or loose components. Ensure that the transmitter is securely mounted and that no parts are missing or damaged.

Wireless Signal Check: Periodically verify the strength and reliability of the wireless communication between the transmitter and the receiver or control system. Ensure that there are no sources of interference and that the signal is stable.

Temperature Reading Verification: Compare the readings from the transmitter with known temperature standards or reference devices to ensure accuracy. If discrepancies are found, investigate potential causes and perform necessary adjustments or calibration.

Cleaning

Schedule Cleaning: Depending on the operating environment and the type of materials in contact with the transmitter, schedule regular cleaning to prevent contamination that might affect performance.

Cleaning Procedure:

Shut Down System: Ensure that the system is turned off and, if necessary, depressurized before cleaning.

Clean the Transmitter: Use a non-abrasive cleaner and a soft cloth to gently clean the exterior of the transmitter. Avoid harsh chemicals or solvents that might damage the device.

Inspect for Contamination: For transmitters with external probes, check and clean the probe area to remove any build-up that could affect temperature measurements.

Calibration

Perform Regular Calibration: Follow the manufacturer’s recommendations for calibration frequency. Regular calibration is essential to maintain measurement accuracy and ensure reliable performance.

Calibration Procedure:

Verify Calibration Schedule: Check and adhere to the manufacturer’s recommended calibration intervals.

Use Calibration Standards: Calibrate the transmitter using temperature standards or reference materials to verify its accuracy.

Adjust Settings: If calibration reveals deviations, adjust the transmitter’s settings as needed to match the reference standards.

Battery and Power Management

Check Power Sources: Regularly inspect the battery or power source to ensure it is functioning correctly. For battery-powered models, monitor battery levels and replace batteries before they are fully depleted.

Inspect Power Connections: Ensure that all power connections are secure and free from corrosion or damage. For wired power sources, check connections to ensure they are intact and reliable.

Manage Energy Harvesting Systems: For transmitters using energy-harvesting features (e.g., solar panels), ensure that the energy source is clean and unobstructed to maintain efficient power generation.

Firmware and Software Updates

Check for Updates: Periodically check for firmware or software updates from the manufacturer. Updates may provide bug fixes, performance improvements, or new features.

Install Updates: Follow the manufacturer’s instructions to download and apply updates. Schedule updates during maintenance windows to minimize disruption to operations.

Data Management

Review Data Logs: Regularly review data logs for any anomalies or patterns that could indicate issues with the transmitter. This review helps in early detection of potential problems.

Backup Data: Ensure that data is backed up regularly, particularly if the transmitter integrates with cloud-based or data management systems.

Troubleshooting

Address Performance Issues: If the transmitter exhibits irregular performance or inaccuracies, follow the troubleshooting steps outlined in the manufacturer’s manual. Common issues might include signal interference, calibration drift, or sensor malfunctions.

Contact Support: For persistent issues or complex problems, contact the manufacturer’s technical support team for assistance and guidance.

Documentation

Record Maintenance Activities: Document all maintenance activities, including inspections, cleaning, calibrations, and repairs. Maintaining detailed records helps track the history of the transmitter and plan future maintenance.

Update Maintenance Logs: Keep updated logs of any changes or updates made to the transmitter’s configuration, software, or hardware.

Training and Best Practices

Train Personnel: Ensure that personnel responsible for operating or maintaining the transmitter are properly trained and familiar with maintenance procedures.

Follow Best Practices: Adhere to industry best practices for the care and handling of temperature transmitters, including avoiding exposure to harsh environments that could damage the equipment.

By following these maintenance procedures, you can help ensure that your wireless temperature transmitter continues to operate effectively, providing accurate temperature measurements and reliable performance throughout its lifespan. Regular maintenance and monitoring are key to preventing issues and extending the life of the equipment.

Q&A

Q: What is a Wireless Temperature Transmitter?

A: A Wireless Temperature Transmitter is a device that measures temperature and wirelessly transmits the data to a monitoring system or control center without the need for physical wiring.

Q: How does a Wireless Temperature Transmitter benefit industrial applications?

A: Wireless Temperature Transmitters eliminate the need for wiring, enabling easy installation, remote monitoring, and real-time temperature data collection in industrial environments, improving efficiency and safety.

Q: What types of temperature sensors are commonly used in Wireless Temperature Transmitters?

A: Wireless Temperature Transmitters can utilize various types of temperature sensors such as thermocouples, RTDs (Resistance Temperature Detectors), thermistors, or infrared sensors based on the specific requirements of the application.

Q: What is the typical wireless range of a Wireless Temperature Transmitter?

A: The wireless range of a Wireless Temperature Transmitter can vary based on the technology used (e.g., Bluetooth, Wi-Fi, Zigbee) and environmental factors, but ranges of up to several hundred meters are common in industrial settings.

Q: How secure is the data transmission in Wireless Temperature Transmitters?

A: Data security is crucial in industrial applications. Wireless Temperature Transmitters incorporate encryption, authentication, and secure communication protocols to ensure the integrity and confidentiality of temperature data.

Q: Can multiple Wireless Temperature Transmitters be integrated to monitor different locations? A: Yes, multiple Wireless Temperature Transmitters can be deployed to monitor temperature variations at various locations within a facility, providing comprehensive temperature data for analysis and control.

Q: What factors should be considered when selecting a Wireless Temperature Transmitter?

A: Factors to consider include temperature range, accuracy, wireless range, battery life, data transmission frequency, compatibility with monitoring systems, and environmental conditions where the transmitter will be deployed.

Feel free to customize these questions or add more based on the specific details of the Wireless Temperature Transmitters you are interested in!

Advantages / Disadvantages

Advantages of Wireless Temperature Transmitters

Wireless temperature transmitters offer several advantages over their wired counterparts. They provide flexibility in terms of installation, enabling the monitoring of temperature in hard-to-reach or hazardous locations. The absence of physical wiring simplifies maintenance and reduces the risk of damage or interference with other equipment. Wireless transmitters can also be easily repositioned or relocated as needed.

In terms of maintenance and management, wireless temperature transmitters may incorporate self-diagnostic capabilities for identifying faults or irregularities in the measurement process. They can also support over-the-air (OTA) firmware updates, allowing for easy software upgrades and ensuring compatibility with evolving wireless protocols or security standards.

Ease of Installation: Wireless temperature transmitters eliminate the need for complex wiring, making installation quick and straightforward, especially in hard-to-reach or remote locations.

Flexibility: Wireless transmitters offer flexibility in terms of placement and relocation, allowing for easy adjustments to changes in the monitoring environment without the constraints of physical cables.

Remote Monitoring: Real-time temperature monitoring and data transmission enable remote access to critical temperature readings, allowing for prompt response to variations or anomalies without the need for on-site visits.

Cost Savings: Wireless temperature transmitters can reduce installation and maintenance costs associated with wiring, conduit, and labor, making them a cost-effective solution for temperature monitoring in industrial settings.

Scalability: Wireless systems can be easily scaled up by adding more transmitters as needed, allowing for expansion or modification of the monitoring network without significant infrastructure changes.

Disadvantages of Wireless Temperature Transmitters

Interference: Wireless signals may be prone to interference from other electronic devices, physical obstructions, or environmental factors, potentially affecting data accuracy and reliability.

Power Source Dependency: Wireless transmitters require a power source, which may be limited in remote or inaccessible locations, requiring careful consideration of power management and battery replacement.

Data Security Concerns: Transmitting temperature data wirelessly introduces security risks such as data interception or unauthorized access, necessitating robust encryption and authentication mechanisms to safeguard sensitive information.

Range Limitations: The wireless range of temperature transmitters may be limited, especially in large industrial facilities or areas with interference, requiring strategic placement of repeaters or signal boosters.

Latency: Wireless communication may introduce latency in data transmission, which could be a concern for applications requiring real-time temperature monitoring and immediate action based on the data received.

By understanding both the advantages and disadvantages of wireless temperature transmitters, businesses can make informed decisions about implementing these devices in their industrial temperature monitoring systems. Proper planning and consideration of these factors can help maximize the benefits and mitigate potential challenges associated with wireless temperature monitoring technologies. I

Applications

Wireless temperature transmitters are suitable for numerous applications across various industries where remote and real-time temperature monitoring is essential. Some common applications where wireless temperature transmitters are beneficial include:

Industrial Monitoring: Wireless temperature transmitters are ideal for monitoring temperature in industrial settings such as manufacturing plants, oil refineries, chemical processing facilities, and food production environments. They allow for continuous monitoring of critical temperatures without the need for manual checks.

HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, wireless temperature transmitters can be used to monitor and regulate temperature levels in buildings, offices, and commercial spaces, ensuring efficient operation and occupant comfort.

Cold Chain Management: For industries like pharmaceuticals, food storage, and logistics, wireless temperature transmitters help in monitoring temperature-sensitive products throughout the supply chain, ensuring that they are stored at optimal temperatures to maintain quality and safety.

Environmental Monitoring: Wireless temperature transmitters are utilized in environmental monitoring applications such as weather stations, agricultural settings, and research facilities to track temperature variations, analyze trends, and study climate changes.

Laboratories and Research: In scientific research, laboratories, and healthcare facilities, wireless temperature transmitters play a crucial role in monitoring temperature-sensitive experiments, samples, vaccines, and storage conditions to maintain integrity and compliance.

Energy Management: Wireless temperature transmitters help in energy management by monitoring temperature levels in heating and cooling systems, optimizing energy usage, and identifying areas for efficiency improvements in commercial and industrial buildings.

Data Centers: In data centers and server rooms, wireless temperature transmitters are used to monitor equipment temperature, prevent overheating, and ensure optimal conditions for the reliable operation of IT infrastructure.

Greenhouses and Agriculture: Wireless temperature transmitters are valuable in greenhouse monitoring for controlling and maintaining optimal growing conditions for plants, crops, and agricultural produce by monitoring temperature variations.

Equipment Monitoring: Wireless temperature transmitters are employed to monitor temperature-sensitive equipment, machinery, and processes in industries like aerospace, automotive, and electronics manufacturing to prevent overheating and avoid potential damage.

Safety Compliance: In environments where temperature monitoring is critical for safety and regulatory compliance, such as industrial ovens, chemical storage facilities, and clean rooms, wireless temperature transmitters ensure adherence to standards and prevent hazards.

These applications showcase the versatility and importance of wireless temperature transmitters in various sectors where accurate and reliable temperature monitoring is essential for operational efficiency, product quality, and maintaining safety standards. If you have a specific application in mind or need more detailed information, feel free to ask for further assistance!

Downloads

SRSACT-Z3 – Temperature Sensors

Drawings

A wireless temperature transmitter is a device designed to measure temperature and wirelessly transmit this data to a central monitoring system or receiver. Also, these transmitters play a crucial role in various industries where monitoring and maintaining temperature levels is critical for operational efficiency, safety, and quality control.

A wireless temperature transmitter is a device designed to measure temperature and wirelessly transmit this data to a central monitoring system or receiver. Also, these transmitters play a crucial role in various industries where monitoring and maintaining temperature levels is critical for operational efficiency, safety, and quality control.