Fixed Injection Quills

$ 198.00 – $ 595.00Price range: $ 198.00 through $ 595.00

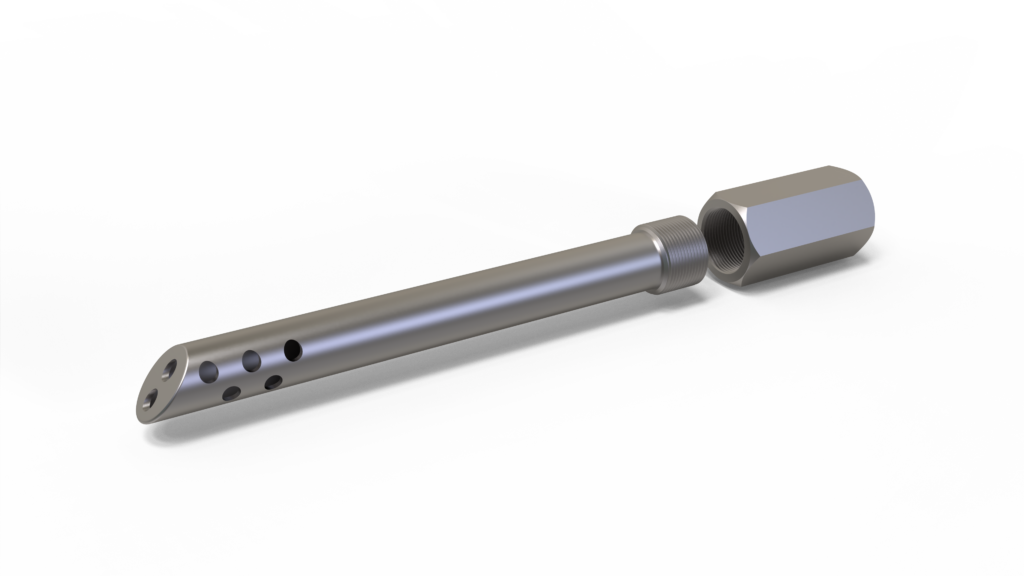

Injection quills are specialized devices designed to introduce fluids into static mixers, enhancing the mixing process across various industries, including chemicals, food production, and pharmaceuticals. These quills facilitate the precise injection of additives, catalysts, or secondary fluids into the primary flow, ensuring a uniform distribution that improves product quality and consistency.

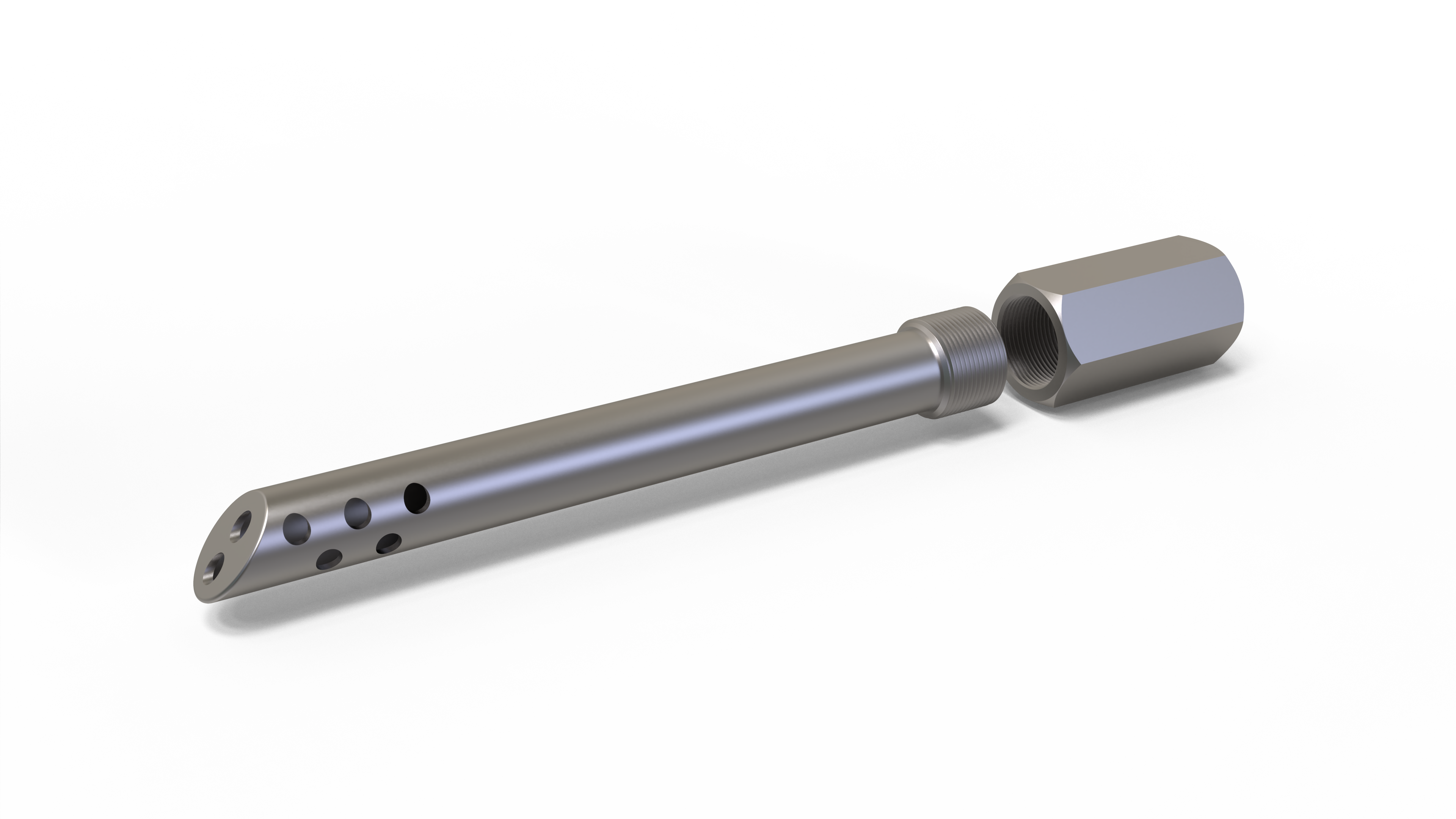

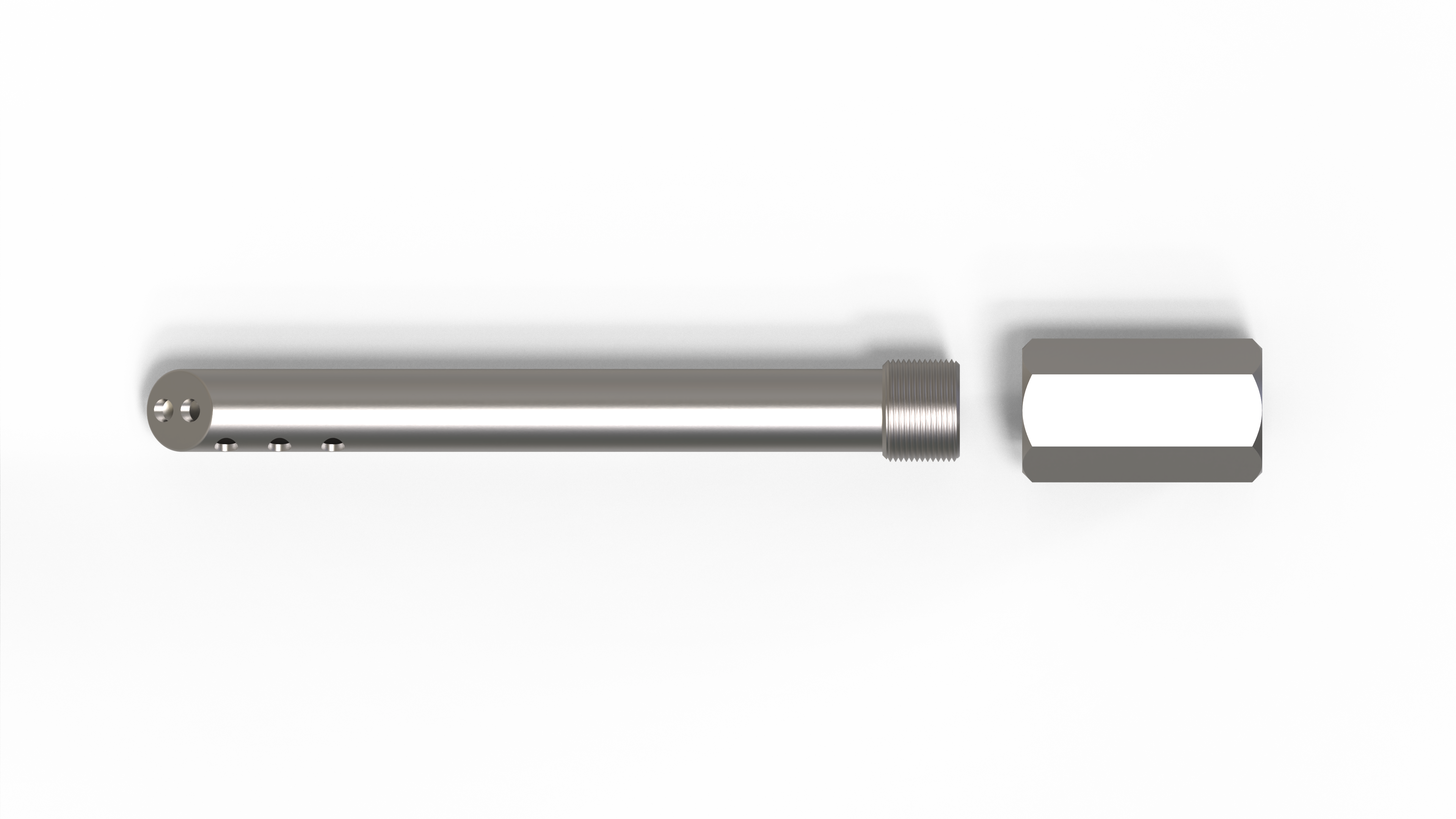

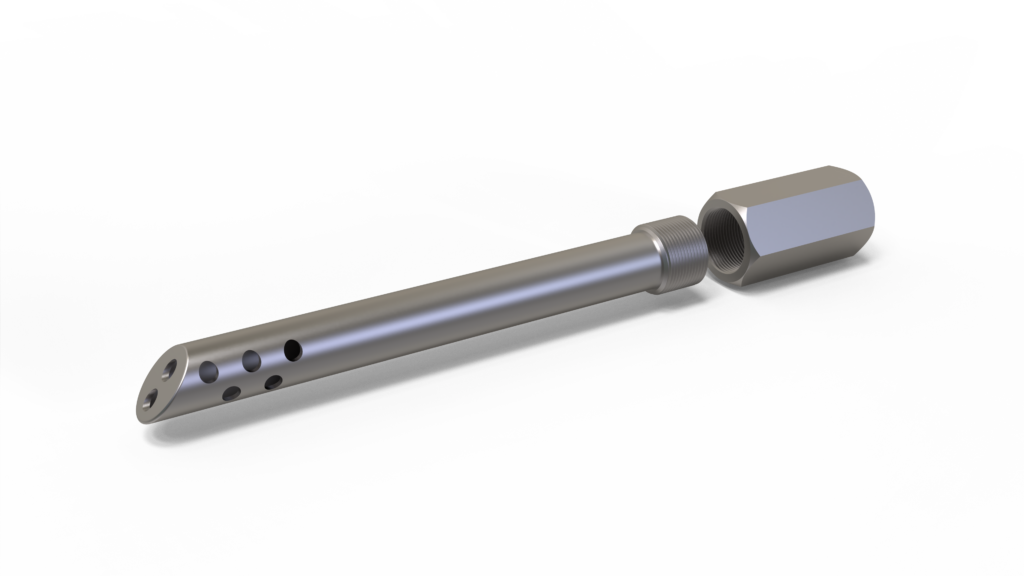

Constructed as tube-like structures, injection quills are strategically placed within static mixers to optimize flow patterns and enhance mixing efficiency. Their design allows for customizable lengths and diameters, catering to specific application requirements while minimizing pressure drop and turbulence. The benefits of using injection quills are substantial; they improve mixing efficiency, reduce energy consumption, and enhance operational flexibility by allowing for the easy addition of various materials as needed.

Additionally, injection quills support stringent quality control measures in industries where product homogeneity is vital, such as pharmaceuticals. However, careful consideration of material compatibility and regular maintenance are essential to ensure optimal performance.

As industries increasingly adopt innovative technologies, the future of injection quills looks promising. Advancements in materials and smart monitoring systems may further enhance their efficiency and reliability, contributing to more sustainable and cost-effective manufacturing processes. Overall, injection quills play a crucial role in optimizing static mixers, paving the way for superior product outcomes and operational efficiencies.

Description

Injection Quills are vital on dispersing a liquid stream center into another flowing liquid stream. The same applies for Gas applications as well. In various industrial applications, ensuring the proper mixing of fluids is crucial for achieving desired product qualities. Static mixers have gained popularity in industries such as chemical processing, food production, and pharmaceuticals for their ability to blend two or more substances efficiently without moving parts. One essential component in this mixing process is the injection quill. This article explores the design, function, applications, and advantages of injection quills in static mixers, highlighting their role in enhancing mixing efficiency and product quality.

Injection Quills are vital on dispersing a liquid stream center into another flowing liquid stream. The same applies for Gas applications as well. In various industrial applications, ensuring the proper mixing of fluids is crucial for achieving desired product qualities. Static mixers have gained popularity in industries such as chemical processing, food production, and pharmaceuticals for their ability to blend two or more substances efficiently without moving parts. One essential component in this mixing process is the injection quill. This article explores the design, function, applications, and advantages of injection quills in static mixers, highlighting their role in enhancing mixing efficiency and product quality.

Understanding Injection Quills

Injection quills are specialized devices designed to introduce one or more fluids into a static mixer. Typically, they are installed at specific points along the length of the mixer and facilitate the injection of materials such as additives, catalysts, or secondary fluids into the primary flow stream. The design of these quills is critical for ensuring optimal mixing and preventing issues like dead zones or channeling.

The primary function of injection quills is to create a uniform distribution of injected materials throughout the main flow. By doing so, they enhance the efficiency of the mixing process, leading to improved product consistency and quality. This is particularly important in applications where precise ratios of components are required.

Design and Functionality

The design of injection quills varies depending on the specific application, but they typically consist of a tube-like structure that allows materials to be injected into the static mixer. One end of the quill is connected to a feed line, while the other end is positioned within the static mixer. The quill’s internal geometry is designed to optimize flow patterns, ensuring that the injected fluid is evenly distributed.

Several factors influence the effectiveness of an injection quill, including its length, diameter, and orientation. The length of the quill should be sufficient to allow adequate mixing without causing excessive pressure drop or turbulence. The diameter must be chosen carefully to prevent blockages and ensure smooth fluid flow. Additionally, the angle at which the quill is positioned can impact how well the injected material integrates with the primary flow.

Applications of Injection Quills in Static Mixers

Injection quills are utilized in a wide range of industries, each with specific requirements for mixing processes. In the chemical industry, for instance, they are often used to introduce catalysts or other additives into reactions. The precise control offered by injection quills ensures that the reaction proceeds at the desired rate, ultimately enhancing yield and efficiency.

In the food and beverage sector, injection quills can add flavorings, preservatives, or colorants during the mixing process. The ability to introduce these components uniformly allows manufacturers to maintain consistent product quality and flavor profiles across large batches.

The use of injection quills also benefits pharmaceutical manufacturing. In this industry, strict adherence to formulation specifications is vital. Injection quills facilitate the accurate blending of active ingredients with excipients, ensuring that medications are produced with the correct potency and homogeneity.

Advantages of Using Injection Quills

The incorporation of injection quills in static mixers offers several notable advantages. One of the primary benefits is improved mixing efficiency. By allowing for the precise injection of materials at the optimal points within the mixer, quills enhance the overall homogeneity of the final product. This leads to more consistent quality and can reduce the likelihood of defects or variability.

Another significant advantage is the reduction of energy consumption. Static mixers are known for their low-pressure drop characteristics, and when combined with injection quills, they can further optimize energy use. By minimizing the need for additional pumping or agitation equipment, manufacturers can achieve cost savings while maintaining high mixing performance.

Injection quills also enhance the flexibility of mixing operations. They allow for the easy addition of different materials as needed, enabling manufacturers to adjust formulations without significant downtime. This adaptability is particularly beneficial in industries that require rapid changes in production, such as specialty chemicals or food processing.

Considerations for Implementation

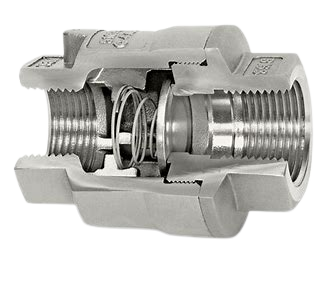

While injection quills offer many benefits, several considerations must be taken into account during implementation. One critical factor is the compatibility of materials. The injected fluids must be compatible with both the primary flow and the materials used in the construction of the quill and static mixer. Incompatibility can lead to reactions that may compromise product quality or damage equipment.

Another consideration is the maintenance of them. Over time, deposits or blockages may occur, especially when working with viscous materials or fluids containing solids. Regular maintenance schedules and inspections can help mitigate these issues, ensuring consistent performance and longevity of the equipment.

Furthermore, proper sizing and placement of injection quills are essential. Engineers must carefully analyze flow dynamics to determine the optimal locations for quill installation. Computational fluid dynamics (CFD) simulations can be valuable tools in this process, allowing for the visualization of flow patterns and the prediction of mixing efficiency.

The Future of Injection Quills in Static Mixers

As industries continue to evolve and embrace new technologies, the role in static mixers is expected to grow. Innovations in materials and designs are paving the way for more efficient and reliable injection systems. For instance, advancements in polymer technology may lead to the development of quills that are more resistant to wear and corrosion, further enhancing their longevity and performance.

Moreover, the integration of smart technologies is likely to influence the future of injection quills. Real-time monitoring systems could be developed to track flow rates, pressures, and material properties, providing operators with valuable data to optimize mixing processes on-the-fly. This data-driven approach would enable manufacturers to achieve even greater precision and efficiency in their operations.

In the context of sustainability, there is also a growing emphasis on reducing waste and energy consumption in industrial processes. They can contribute to these goals by facilitating the precise dosing of additives. Also, they can reduce the amount of material required for effective mixing. This not only benefits the environment but can also lead to significant cost savings for manufacturers.

Conclusion

Injection quills are a vital component in the functionality of static mixers, providing a means to introduce various fluids into the mixing process. This is done with precision and efficiency. Their design and application play a significant role in enhancing mixing performance across a variety of industries. This includes chemicals, food production, and pharmaceuticals. With their ability to improve product quality, reduce energy consumption, and increase operational flexibility, injection quills are poised to remain an essential technology in industrial mixing processes. As innovations continue to emerge, the future of injection quills looks promising. They offer opportunities for even greater efficiencies and advancements in manufacturing.

Specifications

Installation

Injection quills are essential components used for introducing chemicals or additives into processes. Proper installation is crucial for optimal performance and safety. This guide outlines the installation procedures for injection quills.

Safety Precautions

Before beginning installation, ensure all safety protocols are followed. Wear appropriate personal protective equipment (PPE) and ensure the work area is clear of hazards.

Tools and Materials Needed

Gather the necessary tools and materials, including:

- Injection quill assembly

- Wrenches or pliers

- Teflon tape or thread sealant

- Safety goggles and gloves

- Clean cloths for any spills

Preparation of the Site

- Identify the installation location, ensuring it is suitable for the specific application.

- Shut down any systems that will be affected during the installation.

- Flush the line to remove any residual substances.

Assembling the Injection Quill

- Inspect the injection quill for any damage or defects.

- Attach the quill to the designated fitting or port using appropriate connectors.

- Apply Teflon tape or thread sealant to the threads to ensure a leak-free connection.

Securing the Quill

- Tighten the connections securely using wrenches or pliers.

- Be careful not to over-tighten, as this may damage the threads or the quill.

Connecting the Injection Line

- Connect the injection line to the quill, ensuring a snug fit.

- Secure the line using appropriate clamps or fasteners to prevent leaks.

Testing for Leaks

- Once the installation is complete, restore the system and gradually increase pressure.

- Monitor all connections for any signs of leakage.

- If leaks are detected, shut down the system and rectify the connections.

Final Checks and System Start-Up

- Ensure all tools and materials are cleared from the installation area.

- Double-check that all connections are tight and secure.

- Start the system according to the manufacturer’s guidelines and monitor the injection quill for proper operation.

Conclusion

Following these installation procedures will help ensure the effective and safe operation of injection quills. Regular maintenance and inspection are recommended to prolong the lifespan and efficiency of the system.

Maintenance

Regular maintenance of injection quills is essential for ensuring their efficiency, reliability, and safety. This guide outlines the recommended maintenance procedures to keep injection quills in optimal condition.

Safety Precautions

Before performing any maintenance, ensure all safety protocols are in place. Wear appropriate personal protective equipment (PPE) and ensure the area is well-ventilated.

Routine Inspection

- Conduct visual inspections of the injection quill at regular intervals.

- Look for signs of wear, corrosion, or damage to the quill and its connections.

- Check for any leaks around the fittings and connections.

Cleaning the Injection Quill

- Disconnect the quill from the injection line following safety protocols.

- Use a clean cloth or appropriate cleaning solution to remove any buildup or residue on the quill.

- Rinse with water if necessary, ensuring all cleaning agents are removed.

Checking Connections and Seals

- Inspect all threaded connections and seals for signs of wear or damage.

- Replace any damaged seals or gaskets with new ones to maintain a leak-free environment.

- Reapply Teflon tape or thread sealant as needed.

Functional Testing

- Reconnect the injection line and ensure all connections are secure.

- Gradually restore pressure to the system and monitor the quill for proper operation.

- Verify that the injection flow rate is within the specified range for your application.

Calibration and Adjustment

- If applicable, check the calibration of any associated flow meters or control systems.

- Make necessary adjustments to ensure the system operates within desired parameters.

Documentation

- Maintain a maintenance log that records inspection dates, findings, and any actions taken.

- Document any replacement parts used and the conditions observed during inspections.

Scheduled Maintenance

- Establish a regular maintenance schedule based on the manufacturer’s recommendations and operational conditions.

- Include detailed procedures for more in-depth inspections or repairs as needed.

Conclusion

Regular maintenance of injection quills not only enhances their performance but also extends their lifespan. Adhering to these procedures will help ensure safe and effective operation within your system.

Q&A

Q: What is an injection quill?

A: An injection quill is a device used to introduce chemicals or additives into a fluid stream. It is designed to ensure even distribution and proper mixing of the injected substances.

Q: Why is proper installation of injection quills important?

A: Proper installation is crucial to prevent leaks, ensure accurate dosing, and maintain system integrity. Poor installation can lead to chemical spills, reduced efficiency, and potential hazards.

Q: How often should injection quills be inspected?

A: Injection quills should be inspected regularly as part of a maintenance schedule. The frequency can depend on the application, but quarterly inspections are generally recommended.

Q: What are common signs of wear or damage on an injection quill?

A: Look for corrosion, cracks, leaks at the connections, or buildup of materials around the quill. Any noticeable changes in flow rate can also indicate issues.

Q: What should I do if I find a leak during inspection?

A: If a leak is detected, shut down the system immediately and assess the connections. Tighten or replace damaged seals and gaskets, then test for leaks again before restarting the system.

Q: Can I clean an injection quill?

A: Yes, you should clean the injection quill as part of routine maintenance. Disconnect it safely and use a clean cloth or suitable cleaning solution to remove any buildup.

Q: What types of chemicals can be injected with a quill?

A: Injection quills can handle a wide range of chemicals, including acids, bases, and various additives. Always consult the manufacturer’s specifications to ensure compatibility.

Q: How do I know if my injection quill needs calibration?

A: Calibration should be checked regularly, especially if there are noticeable changes in flow rates or if the system is not performing as expected. Refer to the manufacturer’s guidelines for specific calibration procedures.

Q: What safety precautions should I take during maintenance?

A: Always wear appropriate personal protective equipment (PPE), ensure good ventilation, and follow all safety protocols specific to the chemicals being handled.

Q: How can I extend the lifespan of my injection quill?

A: Regular maintenance, prompt repairs, and using the quill within its specified limits can significantly extend its lifespan. Keeping a detailed maintenance log can also help track its performance over time.

Advantages / Disadvantages

Advantages of Injection Quills

Efficient Chemical Dispersion

Injection quills provide uniform mixing of chemicals within a fluid stream, ensuring effective treatment or enhancement of the primary process.

Versatility

They can be used with a wide range of chemicals, including acids, bases, and various additives, making them suitable for diverse applications in different industries.

Easy Installation and Maintenance

Injection quills are relatively straightforward to install and maintain, allowing for quick setup and minimal downtime during maintenance.

Space-Saving Design

Their compact design allows for easy integration into existing systems without requiring significant modifications to the infrastructure.

Enhanced Control

Many injection quills come with adjustable flow rates, enabling precise control over chemical dosing based on specific process requirements.

Cost-Effective

By optimizing chemical usage and improving process efficiency, injection quills can lead to cost savings over time.

Disadvantages of Injection Quills

Potential for Leaks

If not installed or maintained properly, injection quills can develop leaks, leading to chemical spills and environmental hazards.

Wear and Tear

Continuous use can lead to wear and degradation of the quill, necessitating regular inspections and possible replacements.

Dependency on System Compatibility

Injection quills must be compatible with the fluid and chemical being used; incompatibility can lead to failure or reduced effectiveness.

Calibration Needs

Regular calibration may be required to ensure accurate dosing, which adds to maintenance responsibilities.

Pressure Limitations

Some injection quills may have limitations on the pressure they can handle, which could restrict their use in high-pressure applications.

Initial Cost

While they can be cost-effective over time, the initial purchase price of high-quality injection quills may be a concern for some budget-conscious operations.

Applications

Water Treatment

Injection quills are commonly used in water treatment processes, where they introduce chemicals such as chlorine, coagulants, or pH adjusters into the water supply. This ensures effective disinfection, sedimentation, and overall water quality management.

Chemical Processing

In chemical manufacturing, injection quills facilitate the precise addition of various chemicals during production. They are used for the injection of catalysts, reagents, and other additives, contributing to controlled reactions and enhanced product quality.

Oil and Gas Industry

In the oil and gas sector, injection quills play a critical role in enhancing production efficiency. They are used to inject chemicals that prevent corrosion, hydrate formation, or scale buildup in pipelines, ensuring smooth operation and extended equipment life.

Food and Beverage

In the food and beverage industry, injection quills are utilized for the precise dosing of additives, flavorings, and preservatives. This ensures product consistency and safety while complying with stringent regulatory standards.

Pharmaceuticals

Injection quills are essential in pharmaceutical manufacturing, where they facilitate the accurate addition of active ingredients and excipients during the production of medications. This precision is vital for maintaining product efficacy and safety.

Cooling Water Systems

In cooling water systems, injection quills are employed to introduce biocides and scale inhibitors. This helps control microbial growth and scaling, ensuring efficient heat exchange and reducing maintenance costs.

Agriculture

In agricultural applications, injection quills can be used for fertigation, where fertilizers are injected into irrigation systems. This method allows for precise nutrient delivery, promoting healthier crops and optimizing resource use.

Wastewater Treatment

In wastewater treatment facilities, injection quills are utilized to introduce flocculants and other treatment chemicals. This aids in the effective removal of contaminants and improves the overall treatment process.

Industrial Cleaning

In industrial cleaning applications, injection quills are used to add cleaning agents to systems and processes. This ensures thorough cleaning and maintenance, enhancing equipment performance and longevity.

Downloads

Drawings

Injection Quills are vital on dispersing a liquid stream center into another flowing liquid stream. The same applies for Gas applications as well. In various industrial applications, ensuring the proper mixing of fluids is crucial for achieving desired product qualities. Static mixers have gained popularity in industries such as chemical processing, food production, and pharmaceuticals for their ability to blend two or more substances efficiently without moving parts. One essential component in this mixing process is the injection quill. This article explores the design, function, applications, and advantages of injection quills in static mixers, highlighting their role in enhancing mixing efficiency and product quality.

Injection Quills are vital on dispersing a liquid stream center into another flowing liquid stream. The same applies for Gas applications as well. In various industrial applications, ensuring the proper mixing of fluids is crucial for achieving desired product qualities. Static mixers have gained popularity in industries such as chemical processing, food production, and pharmaceuticals for their ability to blend two or more substances efficiently without moving parts. One essential component in this mixing process is the injection quill. This article explores the design, function, applications, and advantages of injection quills in static mixers, highlighting their role in enhancing mixing efficiency and product quality.