Description

Density Flow Meter: A Comprehensive Overview

A density flow meter is an advanced measurement device used to determine the density of a fluid as it flows through a pipeline. Also, these meters are crucial in various industries for applications where fluid density directly affects process control, quality assurance, and operational efficiency. Finally, this detailed description covers the principles, types, components, applications, advantages, limitations, and maintenance of density flow meters.

Principles of Operation

Density flow meters operate on the principle that the density of a fluid is indicative of its mass per unit volume. In addition, measuring the density of a fluid in real-time allows for accurate monitoring and control of processes where density is a critical parameter. Furthermore, the density of a fluid can changes due to variations in temperature, pressure, or composition, and density flow meters help track these changes to ensure consistency and optimize operations.

Types of Density Flow Meters

Several types of density flow meters are available, each employing different technologies to measure fluid density:

Vibrating Element Density Meters

These meters use vibrating sensors to measure density. They consist of a sensor element that vibrates at a specific frequency. Furthermore, when the fluid flows around the vibrating element, changes in density affect the vibration frequency. By analyzing these frequency changes, the meter calculates the fluid’s density. Finally, vibrating element meters are known for their accuracy and are commonly used in the chemical and petrochemical industries.

Gamma Ray Density Meters

Gamma ray density meters utilize radioactive isotopes to measure density. A gamma ray source emits radiation that passes through the fluid and is detected by a receiver on the opposite side. Also, the amount of radiation absorbed by the fluid depends on its density. By measuring the intensity of the detected radiation, the meter calculates the fluid’s density. Finally, these meters are often used in applications where other measurement techniques might be unsuitable, such as in highly corrosive or high-temperature environments.

Ultrasonic Density Meters

Ultrasonic density meters use sound waves to measure density. An ultrasonic transducer sends sound waves through the fluid, and the meter measures the speed at which the sound waves travel. The fluid’s density affects the speed of sound, so the meter determines the density of the fluid by analyzing the travel time and frequency shifts. Finally, ultrasonic meters are advantageous for their non-intrusive measurement and are suitable for a wide range of fluid types.

Hydrostatic Density Meters

Hydrostatic density meters measure density based on the hydrostatic pressure exerted by a fluid column. Additionally, these meters have a sensor that measures the pressure at various depths within the fluid. In addition, by calculating the pressure difference and knowing the height of the fluid column, the meter determines the fluid’s density. Hydrostatic meters are often used in applications involving large tanks or vessels.

Components of a Density Flow Meter

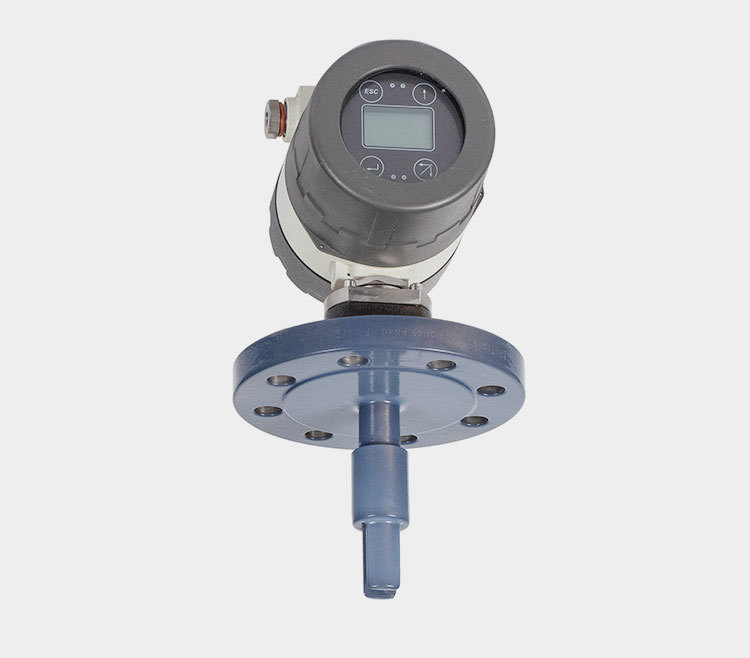

Sensor Element: The sensor is the core component that interacts with the fluid. Depending on the type of density meter, this could be a vibrating element, a gamma ray source and detector, an ultrasonic transducer, or a pressure sensor.

Transmitter: The transmitter processes the signals from the sensor and converts them into a readable density measurement. It may also handle additional functions such as temperature compensation, data logging, and output communication.

Display Unit: The display unit shows the density readings and may provide additional information such as flow rates, temperature, and alarms. In advanced systems, the display could be a digital screen or part of a larger control system interface.

Flow Conditioning Elements: Some density meters include flow conditioning elements such as straightening vanes or flow conditioners. This will ensure a uniform flow profile and accurate measurements.

Housing and Connections: The housing protects the internal components from environmental factors and contains the necessary connections. This necessary connection is for integrating the meter into the pipeline or process system.

Conclusion

A density flow meter is a valuable tool for measuring the density of fluids in real-time. This is with applications spanning various industries including chemical processing, petrochemicals, food and beverage, pharmaceuticals, and environmental monitoring. Additionally, by understanding the principles, types, components, applications, advantages. The limitations of density flow meters, users can effectively utilize these devices to optimize processes. This will ensure product quality and improve operational efficiency. Finally, proper maintenance and calibration are key to ensuring the accuracy and reliability of density measurements. This makes these meters an essential component in many industrial applications.

Specifications

Measure the density, concentration, gravity, and temperature of the liquid

- The accuracy will not be affected by temperature, pressure, density, viscosity, etc.

- Accuracy: ±0.002g/cc; ±0.001g/cc optional

- Applications: pipeline interface detection, mineral slurry solids monitoring, and corrosive acid concentration control; Where fast-response density and concentration monitoring is required.

- Moreover, it Increased installation flexibility with continuous, real-time measurement in pipelines, by-pass loops, and tanks

- Also, Choose from a wide range of corrosion-resistant materials for measuring the density and concentration of critical chemicals Support protocols for connection to DCS, PLC, and flow computers

- Finally, Expand usage with a hazardous area-approved, head-mounted transmitter that supports local configuration and display

Installation

Installation Procedures for a Density Flow Meter

Installing a density flow meter involves several critical steps to ensure accurate measurements and optimal performance. The installation process must be carried out carefully to maintain the integrity of the system and the accuracy of the measurements. Below is a detailed guide for installing a density flow meter:

Planning and Preparation

Review Manufacturer’s Documentation: Thoroughly read the installation manual provided by the manufacturer. This document includes specific instructions, installation requirements, and safety precautions tailored to the particular model of the density flow meter you are using.

Gather Tools and Equipment: Collect all necessary tools and materials for the installation. This typically includes wrenches, pipe cutters, sealants, mounting brackets, and any necessary fittings. Ensure you have the correct components for connecting the flow meter to your piping system.

Select Installation Location: Choose an appropriate location for the flow meter. It should be installed in a straight section of the pipe to ensure accurate measurements. Avoid areas with excessive vibration, temperature extremes, or high levels of particulate matter. Ensure the installation site allows for easy access for maintenance and calibration.

System Preparation

Shut Down the System: Before beginning the installation, turn off the system and depressurize the pipeline. This step is crucial for safety and to prevent any accidental leaks or spills.

Prepare the Installation Site: Clean the pipe or connection point where the density flow meter will be installed. Remove any debris, rust, or old sealant to ensure a clean and secure connection.

Installing the Density Flow Meter

Verify Orientation and Alignment: Ensure the flow meter is oriented correctly according to the manufacturer’s specifications. Most density flow meters should be installed in a vertical position with the flow direction indicated by an arrow on the device. Proper alignment is crucial for accurate measurements.

Install the Flow Meter:

- Threaded Connections: For flow meters with threaded connections, apply a suitable thread sealant to prevent leaks. Screw the meter into the pipe or fitting and tighten securely with a wrench. Avoid over-tightening to prevent damage to the flow meter or pipe.

- Flanged Connections: If the flow meter has flanged connections, align it with the pipe flanges and place any necessary gaskets. Secure the flow meter with bolts, tightening them evenly in a cross pattern to ensure a uniform seal.

Verify Installation: Check that the flow meter is securely installed, and all connections are tight. Ensure the flow meter is aligned correctly and that there are no obstructions or misalignments.

Connecting and Testing

Reconnect the System: Once the flow meter is installed, reconnect the system and gradually reintroduce pressure. Monitor for any leaks around the flow meter and connections.

Test the Flow Meter: Conduct a test run to verify that the flow meter operates correctly. Observe the readings and ensure they match the expected values. Check the flow meter for any signs of instability or interference.

Calibrate the Meter: Perform any necessary calibration according to the manufacturer’s guidelines. Calibration ensures that the flow meter provides accurate density measurements. Use standard calibration fluids if required and adjust settings as needed.

Final Checks and Documentation

Inspect the Installation: Conduct a final inspection to ensure the flow meter is properly installed and functioning as expected. Confirm that there are no leaks and that all connections are secure.

Document the Installation: Record all relevant details about the installation, including the location, connection types, calibration settings, and any observations from the testing phase. This documentation is important for future reference and maintenance.

Provide Training: If necessary, provide training for relevant personnel on how to operate and maintain the flow meter. Ensure they understand how to interpret the readings and what actions to take in case of any issues.

Ongoing Maintenance and Monitoring

Schedule Regular Inspections: Plan regular inspections to check the condition of the flow meter and its performance. Inspect for any signs of wear, damage, or calibration drift.

Monitor Performance: Continuously monitor the performance of the flow meter to ensure accurate measurements. Address any issues promptly to maintain optimal operation.

By following these installation procedures, you can ensure that your density flow meter is set up correctly and provides reliable, accurate measurements for your system. Proper installation and regular maintenance are key to the long-term performance and accuracy of the flow meter.

Maintenance

Routine Inspection: Regularly inspect the density meter for signs of wear, damage, or contamination. Check for any physical damage to the sensor or housing and ensure all connections are secure.

Cleaning: Depending on the fluid being measured, periodic cleaning may be required to prevent buildup or contamination on the sensor element. Follow the manufacturer’s recommendations for cleaning procedures and use appropriate cleaning agents.

Calibration: Regularly calibrate the density meter to ensure accurate measurements. Use standard calibration fluids or procedures as recommended by the manufacturer and adjust the meter as needed based on calibration results.

Component Checks: Inspect and test individual components such as sensors, transmitters, and display units to ensure they are functioning correctly. Replace any faulty components promptly to avoid measurement errors.

Documentation: Maintain detailed records of all maintenance activities, including inspections, cleaning, calibrations, and repairs. This documentation helps track the meter’s performance and plan future maintenance.

Q&A

A Q&A Density Flow Meters, which stands for “question and answer for Density Flow Meters,” is a format commonly used to facilitate communication and exchange of information. Also, in a Q&A, one person asks a question, and another person or group provides an answer or response to that question. In addition, this format is widely used in various contexts, such as interviews, discussions, presentations, or online forums. Furthermore, it allows for a structured and organized way of addressing inquiries and obtaining relevant information. Finally, is there anything specific you would like to know about Q&A Density Flow Meters?

Q: What is a density flow meter?

A: A Q&A Density Flow Meters are a type of flow meter that measures the density of a fluid With this we use that information to calculate the flow rate of the fluid.

Q: How does a density flow meter work?

A: A density flow meter works by measuring the frequency shift of a sound wave that is sent through the fluid. In addition, the frequency shift is proportional to the density of the fluid, which can then be used to calculate the flow rate of the fluid.

Q: What are the advantages of using a density flow meter?

A: Some advantages of using a density flow meter include:

-

- High accuracy and precision in measuring flow rate

-

- Additionally, it can be used for a wide range of fluids, including liquids, gases, and slurries

-

- Can measure both low and high flow rates

-

- Furthermore, it can be used in harsh environments, including high-pressure and high-temperature applications

-

- Also, this can be used to measure the density of the fluid in addition to the flow rate, providing valuable information about the fluid being measured

Q: What are some common applications for density flow meters?

A: Density flow meters are commonly used in a variety of industries, including oil and gas, chemical processing, and food and beverage. Also, they are often used in applications where accurate measurement of flow rate and density is critical. Also, as in custody transfer applications, process control, and quality control.

Q: What are some potential limitations or drawbacks of using a density flow meter?

A: Some potential limitations of using a density flow meter include:

-

- Higher cost compared to other types of flow meters

-

- Can be affected by changes in fluid temperature and pressure, which can affect the accuracy of the meter

-

- Furthermore, it can be sensitive to changes in fluid properties, such as changes in viscosity or density

-

- Also, it can be affected by bubbles or entrained air in the fluid, which can affect the accuracy of the meter

Q: How can a density flow meter be calibrated?

A: A density flow meter can be calibrated using a reference standard, such as a calibrated container or a more accurate flow meter. In addition, the fluid is passed through the density flow meter and the reference standard at the same time. Moreover, the readings from both devices are compared to determine any differences in accuracy. Finally, the meter can then be adjusted accordingly to improve its accuracy.

Q: What materials are density flow meters typically made from?

A: Density flow meters can be made from a variety of materials depending on the application. This includes metals such as stainless steel, titanium, and aluminum, as well as plastics such as PVC and PTFE. Finally, the choice of material depends on factors such as the type of fluid being measured. Other factors are the temperature and pressure of the fluid and the required level of accuracy.

Q: Can density flow meters be used in hazardous or corrosive environments?

A: Density flow meters can be designed and constructed to be used in hazardous or corrosive environments. Moreover, when using materials such as stainless steel or special coatings to resist corrosion. It is also by using explosion-proof housings and other safety features to prevent the risk of fires or explosions.

Q: What is the typical accuracy of a density flow meter?

A: The typical accuracy of a Q&A Density Flow Meter depends on factors such as the flow range. Also, accuracy is impacted by the quality of the sensor, and the calibration method used. Finally, in general, the accuracy of a density flow meter can range from 0.1% to 2% of the actual flow rate.

Q: How does the installation of a density flow meter affect the flow of the fluid being measured?

A: The installation of a density flow meter can affect the flow of the fluid being measured. This is especially true if the meter obstructs the flow path. Also, to minimize the impact of the meter on the flow, it is important to ensure that the meter is installed in a section of the pipe. Furthermore, this is where the flow is fully developed and has a stable velocity profile. Additionally, it is also important to choose a Density flow meter with a low-pressure drop to minimize any impact on the flow rate.

Q: Can density flow meters be used to measure the flow of multiphase fluids?

A: Density flow meters can be used to measure the flow of multiphase fluids, which are fluids that contain a mixture of two or more phases. Also, the phases such as oil and water or gas and liquid. Also, however, the accuracy of the meter may be affected by the presence of multiple phases. Finally, considering this, additional measurements may be needed to accurately determine the flow rate.

Q: What is the maintenance required for density flow meters?

A: The maintenance required for Q&A Density Flow Meters depends on factors such as the type of meter. It also depends upon the application and the environment in which the meter is used. Additionally, in general, regular calibration and cleaning of the meter is recommended to ensure accurate readings. Finally, the meter should also be inspected regularly for any signs of damage or wear. Now, any necessary repairs or replacements should be made promptly to prevent further damage.

Q: Can a density flow meter be used in both liquids and gases?

A: Yes, a density flow meter can be used to measure the flow of both liquids and gases. In addition, this occurs as long as the meter is designed and calibrated for the specific fluid being measured.

Q: What is the cost of a density flow meter?

A: The cost of a Q&A Density Flow Meter can vary widely depending on factors such as the type of meter. Also, you need to consider the size, the materials used, and the level of accuracy required. Also, in general, density flow meters are more expensive than other types of flow meters. Additionally, the prices range from a few hundred dollars for a basic meter to tens of thousands of dollars. These costs are for a high-precision meter.

Buy

Density Flow Meters

Advantages / Disadvantages

Advantages of a Density Flow Meter

The Density Meter offers several advantages over other flow measurement technologies. Some of the notable advantages include:

Real-Time Data: The Meter provides continuous, real-time density and flow rate measurements, enabling prompt response to process variations and ensuring product quality.

Minimal Pressure Drop: Unlike some other flow measurement devices, the Meter has a negligible impact on the fluid flow, resulting in minimal pressure drop.

Wide Dynamic Range: It can handle fluids with a wide range of densities and velocities, making it adaptable to different process conditions.

Accurate Measurements: Density flow meters provide precise measurements of fluid density and flow rates, ensuring reliable data for process control and optimization.

Real-time Monitoring: These meters offer continuous monitoring of density and flow, enabling quick detection of any variations or abnormalities in the fluid being measured.

Versatility: Density flow meters can be used with a wide range of fluids, making them suitable for diverse industrial applications across different sectors.

Improved Process Efficiency: By providing accurate density and flow data, these meters help improve process efficiency, reduce waste, and enhance product quality.

Low Maintenance: Density flow meters are often low-maintenance devices, requiring minimal calibration and upkeep to ensure consistent performance.

Disadvantages of a Density Flow Meter

Cost: Density flow meters can be expensive to purchase and install, making them less budget-friendly compared to some other flow measurement devices.

Sensitivity to Installation Conditions: Proper installation and calibration are crucial for accurate measurements with density flow meters. Factors like pipe size, flow conditions, and fluid properties can impact their performance.

Complex Setup: Some density flow meters may require complex setup procedures or additional equipment for optimal functionality, which can pose a challenge for inexperienced users.

Risk of Contamination: External factors such as impurities or contaminants in the fluid being measured can affect the accuracy and reliability of density flow meters.

Limited Application in Some Fluids: Certain types of fluids or conditions may not be suitable for density flow meter measurements, limiting their applicability in specific environments or industries.

Applications

Density flow meters are used in various industries for diverse applications:

Chemical Processing: In chemical manufacturing, density flow meters ensure that chemical reactions occur under optimal conditions by monitoring the density of reactants and products. Accurate density measurement helps in controlling the concentration and quality of chemical products.

Petrochemical Industry: Density meters are used to measure the density of crude oil, refined products, and various petrochemical fluids. This information is crucial for quality control, blending operations, and compliance with regulatory standards.

Food and Beverage: In the food and beverage industry, density flow meters monitor the density of liquids such as juices, syrups, and dairy products. Maintaining consistent density is essential for product quality and processing efficiency.

Pharmaceuticals: Density flow meters play a role in pharmaceutical manufacturing by ensuring that drug formulations have the correct density. Accurate density measurement is vital for maintaining consistency and efficacy in pharmaceutical products.

Environmental Monitoring: Density meters are used in environmental monitoring to measure the density of water or other fluids in various natural and industrial processes. This data helps in assessing water quality and detecting contamination.

Pipeline interface Inspection, Slurry Solids monitoring, and corrosive acid concentration control; density and concentration monitoring that require rapid response. Furthermore, continuously measure pipelines in real-time with your Meter through pipelines and storage tanks to increase installation flexibility and choose from a variety of corrosion-resistant materials to measure the density and concentration of key chemicals.

Also, it supports protocols connected to DCS, PLC, and Flow computers. Also, pass hazardous area area-approved head-mounted Transmitters extend the range of use, and the transmitter supports local configuration and display.

Drawings