Description

Pulsation dampers, also known as pulsation arrestors or surge suppressors, are devices used to mitigate pressure fluctuations and pulsations in pump systems. These fluctuations are typically caused by the cyclic operation of positive displacement pumps, such as diaphragm, piston, and plunger pumps. When these pumps operate, they create pulsating flow due to their reciprocating action, which can lead to vibrations, noise, and mechanical stress on the pump and associated piping systems. Pulsation dampers play a crucial role in smoothing out these pulsations, ensuring a more stable and continuous flow, thereby enhancing the performance, reliability, and lifespan of the pumping system.

Pulsation dampers, also known as pulsation arrestors or surge suppressors, are devices used to mitigate pressure fluctuations and pulsations in pump systems. These fluctuations are typically caused by the cyclic operation of positive displacement pumps, such as diaphragm, piston, and plunger pumps. When these pumps operate, they create pulsating flow due to their reciprocating action, which can lead to vibrations, noise, and mechanical stress on the pump and associated piping systems. Pulsation dampers play a crucial role in smoothing out these pulsations, ensuring a more stable and continuous flow, thereby enhancing the performance, reliability, and lifespan of the pumping system.

The primary function of a pulsation damper is to absorb the energy of the pressure pulses generated by the pump and release it gradually, thus dampening the pulsations and stabilizing the flow. This is achieved through the use of a compressible gas or an elastomeric bladder within the damper. The damper is installed on the discharge side of the pump, where it acts as a cushion to absorb the pulsations and smooth out the flow before it enters the downstream piping.

What does Pulsation Dampers consist of?

Pulsation dampers typically consist of a cylindrical or spherical chamber that contains a gas-filled bladder or diaphragm. The chamber is filled with a compressible gas, such as nitrogen or air, which acts as the damping medium. When a pressure pulse from the pump enters the damper, the gas compresses, absorbing the energy of the pulse. As the pressure pulse subsides, the gas expands, releasing the absorbed energy and maintaining a steady pressure in the system. This cyclical compression and expansion of the gas smooth out the pulsations, resulting in a more consistent and stable flow.

The design and construction of pulsation dampers vary depending on the specific application and operating conditions. Materials used for the damper body and internal components must be compatible with the pumped fluid and capable of withstanding the operating pressures and temperatures. Common materials include stainless steel, carbon steel, and various high-strength alloys for the body, while the bladder or diaphragm is typically made from elastomers such as EPDM, NBR, or PTFE, depending on the chemical compatibility and temperature requirements.

Effectiveness

The effectiveness of a pulsation damper depends on several factors, including the volume of the gas chamber, the pre-charge pressure of the gas, and the characteristics of the pumped fluid. Proper sizing and selection of the damper are critical to achieving optimal performance. The volume of the gas chamber must be sufficient to absorb the energy of the pressure pulses without excessive compression, while the pre-charge pressure must be set correctly to ensure the damper operates within its effective range. Additionally, the viscosity and compressibility of the pumped fluid, as well as the frequency and amplitude of the pulsations, must be considered when selecting a pulsation damper.

One of the primary benefits of using pulsation dampers is the reduction of vibration and noise in the pumping system. By smoothing out the pulsations, the damper minimizes the mechanical stress on the pump and associated piping, reducing the risk of fatigue and failure. This leads to longer equipment life, lower maintenance costs, and improved overall reliability of the system. Additionally, the reduction in vibration and noise can create a safer and more comfortable working environment for operators and maintenance personnel.

Reasons for Pulsation Dampers

Another significant advantage of pulsation dampers is their ability to improve the accuracy and stability of flow measurements. In many industrial applications, accurate flow measurement is critical for process control and optimization. Pulsations can cause erratic readings from flow meters and other instrumentation, leading to inaccurate measurements and suboptimal process control. By dampening the pulsations, the damper ensures a more stable and continuous flow, allowing for more accurate and reliable flow measurements.

Pulsation dampers also play a crucial role in protecting downstream equipment from the damaging effects of pressure surges and pulsations. Valves, sensors, and other sensitive components can be adversely affected by sudden pressure spikes, leading to premature wear and failure. The dampening effect of the pulsation damper reduces the impact of these pressure surges, protecting the downstream equipment and extending its operational life.

What are they used for?

In addition to their use in positive displacement pump systems, pulsation dampers are also employed in various other applications. This is where pressure fluctuations and pulsations are a concern. These include hydraulic systems, chemical dosing systems, and fluid transfer systems. This occurs in industries such as oil and gas, water treatment, pharmaceuticals, and food and beverage processing. In each of these applications, the dampers help to stabilize the flow, reduce vibration. Finally, it is also used for noise and protect equipment from pressure-related damage.

The installation and maintenance of pulsation dampers are relatively straightforward. Moreover, it is important to follow manufacturer guidelines and best practices to ensure optimal performance. The damper should be installed as close to the pump discharge as possible to maximize its effectiveness. Regular inspection and maintenance of the damper are necessary to ensure it remains in good working condition. This includes checking the pre-charge pressure of the gas and inspecting the bladder or diaphragm. The inspection is for signs of wear or damage, and replacing any components as needed.

One-size-fits-all

Pulsation dampers are highly effective in mitigating pressure pulsations. It is important to note that they are not a one-size-fits-all solution. The specific requirements of the application must be carefully considered to select the appropriate damper. Factors such as the type of pump and the characteristics of the pumped fluid. Also, it is for operating conditions must be taken into account to ensure the damper is properly sized and configured. Consulting with a knowledgeable supplier or engineer can help in selecting the right pulsation damper for the application.

In conclusion, pulsation dampers are essential components in pump systems where pressure fluctuations and pulsations can cause significant issues. By absorbing and dampening the energy of pressure pulses, these devices help to stabilize the flow. It also reduces vibration and noise, protect equipment, and improve the accuracy of flow measurements. Proper selection, installation, and maintenance of pulsation dampers are critical to achieving optimal performance. Also, it is also for reliability in a wide range of industrial applications. Whether in chemical processing, water treatment, or any other industry where pump systems are used. Finally, pulsation dampers play a vital role in ensuring the smooth and efficient operation of the system.

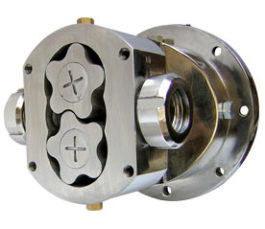

Specifications

General Specifications:

- Model Number: PD-3000

- Type: Inline Hydraulic Pulsation Damper

- Application: Industrial (water and wastewater treatment, oil and gas, chemical processing, food and beverage, etc.)

Performance Specifications:

- Max Flow Rate: 10,000 gallons per minute (GPM)

- Pressure Range: 0-300 psi

- Temperature Range: -20°F to 250°F (-29°C to 121°C)

- Damping Capacity: Up to 95% pulsation reduction

- Volume Capacity: 0.5 to 20 gallons (varies by model)

Construction and Materials:

- Body Material: Carbon steel, stainless steel 304/316, or duplex stainless steel (optional)

- Bladder Material: Nitrile (Buna-N), EPDM, Viton, or PTFE (based on fluid compatibility)

- Seals and Gaskets: EPDM, Viton, or PTFE

- Connection Type: Flanged (ANSI, DIN) or threaded (NPT, BSP)

Operational Features:

- Pressure Relief Valve: Integrated or external (optional)

- Charging Valve: Standard Schrader valve for air/nitrogen charging

- Mounting Options: Vertical or horizontal installation

- Inspection Port: For easy internal inspection and maintenance

Control System:

- Monitoring: Pressure gauge, electronic pressure transducer (optional)

- Control Interface: Manual or PLC-based control panel

- Alarm System: High/low pressure alarms, bladder failure alarm (optional)

Installation Requirements:

- Inlet/Outlet Size: 1 to 12 inches (customizable)

- Mounting Space: Minimum clearance of 24 inches around the unit for maintenance access

- Power Supply (if required): 110/220V AC, 50/60 Hz for electronic monitoring systems

- Foundation: Concrete pad or steel structure capable of supporting the damper’s weight when fully loaded

Maintenance and Service:

- Bladder Replacement: Easy-access design for quick replacement

- Inspection Interval: Recommended bi-annual inspection

- Maintenance Kit: Includes replacement bladder, seals, and gaskets

- Documentation: Comprehensive user manual with maintenance schedule and troubleshooting guide

Compliance and Standards:

- Compliance: ASME Section VIII, CE, ISO 9001

- Certifications: ATEX (for explosive environments), NSF (for potable water applications)

- Environmental Standards: RoHS, REACH compliant

Additional Features:

- Custom Coatings: Epoxy, PTFE, or other coatings for enhanced corrosion resistance

- Remote Monitoring: Optional wireless connectivity for remote monitoring and control

- Warranty: 2-year standard warranty, extendable to 5 years with maintenance contract

- Service Support: 24/7 technical support and on-site service available

By specifying these detailed characteristics, the pulsation damper can be tailored to meet the precise requirements of various industrial applications, ensuring reliable and efficient performance.

Installation

Preparation

Read the Manufacturer’s Manual:

Review the manufacturer’s installation and maintenance manual thoroughly. Ensure you understand all the specific instructions and recommendations provided for the pulsation damper model you are installing.

Safety Precautions:

Ensure the system is depressurized and drained before starting the installation process. Follow all relevant safety protocols, including wearing appropriate personal protective equipment (PPE).

Gather Tools and Materials:

Prepare all necessary tools and materials, including wrenches, sealants, mounting brackets, and any other equipment specified by the manufacturer.

Installation Steps

Select Installation Location:

Choose a location as close to the pump discharge as possible. This proximity maximizes the damper’s effectiveness in absorbing pulsations.

Check for Proper Orientation:

Ensure the damper is oriented correctly according to the manufacturer’s specifications. Most pulsation dampers have an inlet and outlet marked on the body that must align with the flow direction.

Install Mounting Brackets:

Secure the mounting brackets or supports, if required. Make sure the damper is firmly mounted to minimize vibrations and movement during operation.

Connect the Damper to the Pump Discharge:

Use appropriate fittings and piping to connect the damper to the pump discharge line. Ensure that all connections are secure and leak-free. Use thread sealant or tape if specified by the manufacturer.

Pre-Charge the Damper:

Pre-charge the damper with the specified gas (usually nitrogen) to the recommended pressure. This pressure is often detailed in the manufacturer’s manual and is critical for optimal damper performance. Use a pressure gauge to monitor and adjust the pressure accurately.

Check for Proper Sealing:

Inspect all connections and seals to ensure there are no leaks. Tighten connections as necessary.

Install Pressure Relief Valve (if required):

Some installations may require a pressure relief valve. Install this according to the manufacturer’s guidelines to protect the system from over-pressurization.

Integration with Control System (if applicable):

If the pulsation damper includes sensors or is integrated into a control system, connect the appropriate electrical or signal lines. Ensure all connections are secure and follow the manufacturer’s instructions for calibration and integration.

Post-Installation

System Pressurization:

Gradually pressurize the system and monitor for any leaks or abnormal conditions. Check the pressure in the damper to ensure it remains within the specified range.

Operational Testing:

Start the pump and observe the system’s performance. Verify that the pulsation damper is effectively reducing pulsations and stabilizing the flow. Monitor for any unusual vibrations, noise, or pressure fluctuations.

Final Inspection:

Perform a thorough inspection of the entire installation. Ensure all components are securely fastened and that the system is operating smoothly.

Documentation:

Record the installation details, including the pre-charge pressure, any adjustments made, and observations during the operational testing. This documentation will be useful for future maintenance and troubleshooting.

By following these detailed installation procedures, you can ensure that the pulsation damper is installed correctly and operates effectively, providing optimal performance and longevity for your pump system. Proper installation and regular maintenance are key to maximizing the benefits of the pulsation damper and ensuring a stable and efficient pumping operation.

Maintenance

Regular Inspections:

Periodically inspect the damper for signs of wear, damage, or leaks. Check the pre-charge pressure regularly and adjust as necessary.

Bladder or Diaphragm Replacement:

Follow the manufacturer’s guidelines for replacing the bladder or diaphragm. This is typically required at regular intervals or if any performance issues are detected.

System Performance Monitoring:

Continuously monitor the system’s performance. Any increase in pulsations, noise, or vibrations may indicate a need for maintenance or adjustment of the pulsation damper.

Q&A

Q: What is a pulsation damper?

A: A pulsation damper is a device used to reduce pressure fluctuations and pulsations in pump systems, particularly those caused by positive displacement pumps. It absorbs the energy from the pressure pulses generated by the pump, smoothing out the flow and minimizing vibrations and noise.

Q: How does a pulsation damper work?

A: A pulsation damper typically contains a gas-filled bladder or diaphragm within a chamber. When a pressure pulse from the pump enters the damper, the gas compresses, absorbing the pulse’s energy. As the pressure pulse subsides, the gas expands, releasing the absorbed energy and maintaining steady pressure, thereby stabilizing the flow.

Q: Where is a pulsation damper installed in a pump system?

A: A pulsation damper is usually installed on the discharge side of the pump, as close to the pump as possible, to maximize its effectiveness in absorbing pressure pulses and stabilizing the flow before it enters the downstream piping.

Q: What materials are pulsation dampers made from?

A: Pulsation dampers can be made from various materials depending on the application. Common materials for the body include stainless steel, carbon steel, and high-strength alloys. The bladder or diaphragm is often made from elastomers like EPDM, NBR, or PTFE to ensure chemical compatibility and durability.

Q: Why is reducing pulsations important in pump systems?

A: Reducing pulsations is crucial because it minimizes mechanical stress on the pump and piping, reduces vibration and noise, and protects downstream equipment from pressure surges. This leads to longer equipment life, lower maintenance costs, and improved reliability and performance of the system.

Q: Can pulsation dampers improve flow measurement accuracy?

A: Yes, pulsation dampers can significantly improve flow measurement accuracy by stabilizing the flow and reducing erratic readings caused by pressure pulsations. This results in more reliable and precise flow measurements, which are essential for process control and optimization.

Q: What factors should be considered when selecting a pulsation damper?

A: When selecting a pulsation damper, consider factors such as the type of pump, the characteristics of the pumped fluid, operating pressures and temperatures, the volume of the gas chamber, and the pre-charge pressure of the gas. Proper sizing and material selection are crucial for optimal performance.

Q: Are pulsation dampers used in specific industries?

A: Pulsation dampers are used in various industries, including chemical processing, oil and gas, water treatment, pharmaceuticals, and food and beverage processing. They are essential in any application where pump-induced pressure pulsations can cause operational issues or equipment damage.

Q: How often should a pulsation damper be maintained?

A: Regular maintenance of a pulsation damper includes checking the pre-charge pressure of the gas, inspecting the bladder or diaphragm for wear or damage, and replacing any worn components. The frequency of maintenance depends on the operating conditions and the manufacturer’s recommendations.

Q: What are the benefits of using a pulsation damper?

A: The benefits of using a pulsation damper include reduced vibration and noise, extended equipment life, improved flow measurement accuracy, enhanced system reliability, and protection of downstream equipment from pressure surges. These benefits contribute to overall operational efficiency and cost savings.

Advantages / Disadvantages

Advantages of Pulsation Dampers

Smooth Flow: Provides a more stable fluid flow by minimizing pulsation.

Reduced Vibration: Decreases vibrations in the piping system, preventing damage to pipes and fittings.

Extended Equipment Life: Protects pumps, valves, and other equipment from wear and tear.

Prevent Cavitation: Maintains consistent pressure to prevent cavitation in pumps.

Energy Savings: Smoother flow requires less energy, leading to potential energy savings.

Noise Reduction: Dampens pulsations, significantly reducing noise levels in the system.

Versatility: Can be used across various industries, including chemical processing, oil and gas, water treatment, and food and beverage.

Adaptability: Effective with a variety of fluids, including liquids, gases, and slurries.

Easy Integration: Can be easily integrated into existing systems without significant modifications.

Low Maintenance: Typically requires minimal maintenance, adding to their convenience and cost-effectiveness.

Disadvantages of Pulsation Dampers

Initial Cost: The initial cost of purchasing and installing pulsation dampers can be relatively high.

Space Requirements: Requires additional space in the system layout, which may be a limitation in compact environments.

Maintenance Needs: While generally low maintenance, they may still require periodic inspections and servicing to ensure optimal performance.

Potential for Issues: Over time, there may be potential maintenance issues that necessitate attention.

Applications

Water and Wastewater Treatment

Municipal Water Treatment: Ensures a consistent supply of clean water by minimizing pulsation and protecting pumps and valves.

Industrial Wastewater Treatment: Reduces vibrations and wear on equipment, leading to more efficient treatment processes.

Desalination Plants: Enhances the performance and longevity of high-pressure pumps used in reverse osmosis systems.

Oil and Gas Industry

Pipeline Systems: Stabilizes pressure fluctuations to prevent pipeline damage and ensure smooth transport of oil and gas.

Drilling Operations: Reduces pulsations in drilling mud pumps, protecting drilling equipment and enhancing drilling efficiency.

Refineries: Ensures smooth operation of pumps and compressors, reducing maintenance costs and downtime.

Chemical and Pharmaceutical Industry

Chemical Processing: Maintains consistent flow and pressure, crucial for accurate chemical reactions and product quality.

Pharmaceutical Manufacturing: Protects sensitive equipment and ensures precise dosing and mixing of ingredients.

Batch Processing: Enhances the stability and efficiency of batch processing systems by reducing pulsations.

Food and Beverage Industry

Beverage Production: Ensures consistent flow in bottling and canning lines, reducing spillage and waste.

Dairy Processing: Stabilizes pressure in pasteurization and homogenization processes, ensuring product quality.

Food Processing: Protects pumps and valves in processing lines, leading to longer equipment life and reduced maintenance.

Power Generation

Hydroelectric Plants: Reduces pressure fluctuations in water turbines, enhancing efficiency and reducing wear.

Thermal Power Plants: Ensures stable flow in cooling systems and feedwater pumps, improving overall plant efficiency.

Nuclear Power Plants: Protects critical cooling and reactor feed systems by maintaining consistent pressure and flow.

Pulp and Paper Industry

Paper Manufacturing: Stabilizes pressure in pulp processing and paper-making machines, improving product quality and equipment longevity.

Chemical Pulping: Ensures consistent flow and pressure in chemical pulping processes, enhancing efficiency and product quality.

Recycling Processes: Protects pumps and reduces vibrations in water recycling systems used in paper mills.

Automotive Industry

Paint Booths: Ensures smooth operation of paint spray systems, improving paint finish quality.

Fluid Transfer Systems: Stabilizes pressure in fluid transfer systems, protecting pumps and valves and ensuring consistent flow.

Manufacturing Equipment: Reduces vibrations and wear on pumps and compressors used in automotive manufacturing processes.

Mining and Mineral Processing

Slurry Transport: Reduces pulsations in slurry pumps, protecting pipelines and ensuring efficient transport of mineral slurries.

Flotation Processes: Stabilizes pressure and flow in flotation cells, enhancing mineral separation efficiency.

Dewatering Systems: Ensures consistent flow in dewatering pumps, improving efficiency and equipment longevity.

Agriculture and Irrigation

Irrigation Systems: Maintains consistent pressure in drip and sprinkler systems, ensuring uniform water distribution.

Fertilizer Injection Systems: Ensures smooth operation of fertilizer injection pumps, enhancing efficiency and accuracy.

Livestock Watering Systems: Protects pumps and valves in livestock watering systems, ensuring reliable water supply.

HVAC Systems

Chilled Water Systems: Reduces pulsations in chilled water pumps, improving system efficiency and reducing noise.

Heating Systems: Stabilizes pressure in hot water and steam heating systems, protecting equipment and ensuring consistent heat distribution.

Ventilation Systems: Ensures smooth operation of ventilation fans and air handling units, reducing wear and noise.

By being used in these diverse applications, pulsation dampers play a critical role in enhancing system performance, protecting equipment, and ensuring consistent and efficient operation.

Drawings

Pulsation dampers, also known as pulsation arrestors or surge suppressors, are devices used to mitigate pressure fluctuations and pulsations in pump systems. These fluctuations are typically caused by the cyclic operation of positive displacement pumps, such as diaphragm, piston, and plunger pumps. When these pumps operate, they create pulsating flow due to their reciprocating action, which can lead to vibrations, noise, and mechanical stress on the pump and associated piping systems. Pulsation dampers play a crucial role in smoothing out these pulsations, ensuring a more stable and continuous flow, thereby enhancing the performance, reliability, and lifespan of the pumping system.

Pulsation dampers, also known as pulsation arrestors or surge suppressors, are devices used to mitigate pressure fluctuations and pulsations in pump systems. These fluctuations are typically caused by the cyclic operation of positive displacement pumps, such as diaphragm, piston, and plunger pumps. When these pumps operate, they create pulsating flow due to their reciprocating action, which can lead to vibrations, noise, and mechanical stress on the pump and associated piping systems. Pulsation dampers play a crucial role in smoothing out these pulsations, ensuring a more stable and continuous flow, thereby enhancing the performance, reliability, and lifespan of the pumping system.