A UL (Underwriters Laboratories) panel building shop is an industrial facility that is certified to produce and assemble electrical control panels. This is in accordance with the safety and performance standards set by UL.

UL (Underwriters Laboratories) is a globally recognized independent safety science company that offers a variety of services, including the certification of panel-building products. The UL Panel Building Certification ensures that the evaluated products meet specific safety and performance requirements.

What is Panel Building

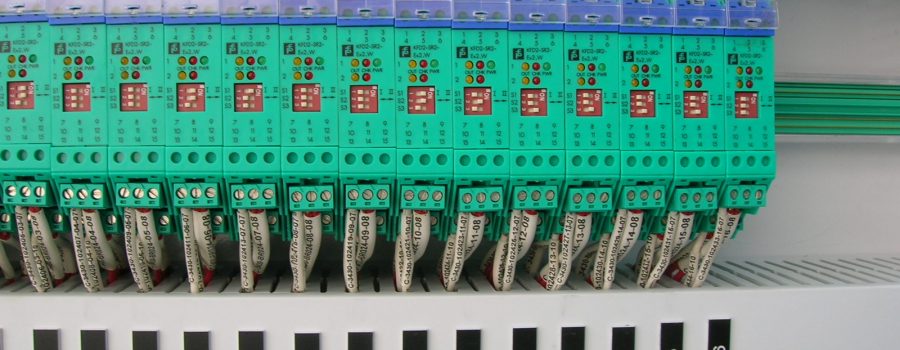

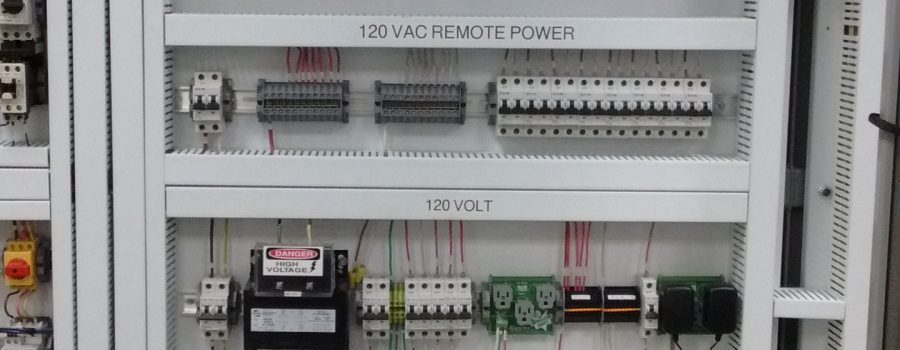

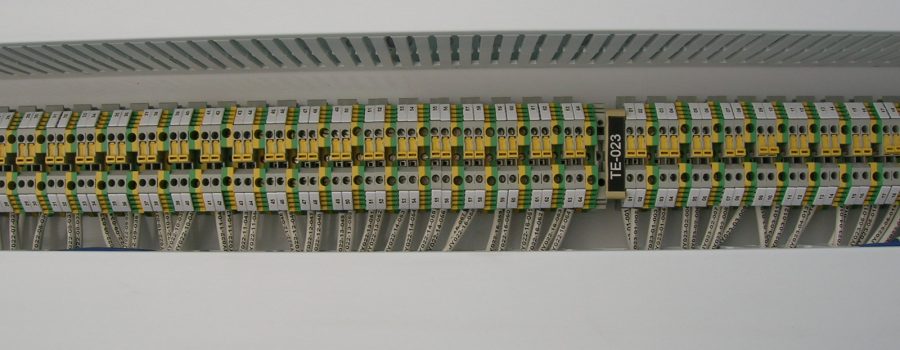

Panel building refers to the construction of electrical control panels and related equipment used in various industries, such as manufacturing, automation, and energy. These panels are responsible for controlling and distributing electrical power and signals, making them critical components of any electrical system.

The UL Panel Building Certification process involves a series of tests, inspections, and evaluations to ensure that the products comply with UL’s safety standards and other applicable industry regulations. Let’s delve deeper into the certification process to understand it better.

Application

First, a manufacturer applies for UL certification for their panel building products. The certification process involves submitting comprehensive documentation, including product designs, manufacturing processes, and parts used. This documentation is reviewed by UL experts who assess whether the product meets the necessary safety requirements and performance criteria.

Once the documentation review is complete, UL performs a series of tests on the products. These tests cover various aspects of the panel building products, such as electrical safety, environmental performance, and fire resistance. The specific tests conducted depend on the type of product being certified.

Safety Tests

For instance, electrical safety tests may include dielectric voltage withstand, short circuit current rating, and ground continuity verification. Environmental tests may include exposure to extreme temperatures, humidity, and vibrations, simulating the conditions that the product may be exposed to during its lifespan. Fire resistance tests evaluate the product’s ability to withstand fire hazards and prevent the spread of flames.

During the certification process, UL also conducts factory audits to verify the manufacturer’s production capabilities and quality control processes. These audits aim to ensure that the manufacturer consistently produces products that meet the required safety standards.

Testing

Once the testing and auditing processes are complete, UL issues the appropriate certification, indicating that the panel building products comply with the established standards and regulations. The UL mark, a widely recognized symbol of safety, can then be affixed to the certified products.

The UL Panel Building Certification offers several benefits to both manufacturers and end-users. For manufacturers, the certification demonstrates their commitment to producing safe and reliable products. It also helps them gain a competitive advantage by differentiating their products in the market. Furthermore, UL’s reputation as a trusted certification body enhances the manufacturer’s credibility.

UL Mark

For end-users, the UL mark on panel-building products provides assurance of their safety and performance. Certified products are less likely to cause electrical hazards or malfunction, resulting in improved overall system reliability. Additionally, using UL-certified products can help organizations meet regulatory requirements, ensuring compliance with relevant safety codes and standards.

It’s worth mentioning that UL continually updates its standards to keep up with evolving technologies and safety requirements. As a result, manufacturers must regularly renew their certifications to ensure ongoing compliance with the latest standards and regulations. This process helps maintain the highest level of safety and performance for panel-building products.

Here are some of the reasons why having a UL panel building shop is important:

- Compliance with safety standards: UL is a globally recognized safety certification organization that sets rigorous safety standards for electrical equipment and components. Building electrical control panels in compliance with UL standards ensures that the panels are safe to use and meet regulatory requirements.

- Risk reduction: Electrical panels that do not meet safety standards can pose significant risks to personnel, equipment, and facilities. In the event of an electrical hazard, compliance with UL standards can limit the risks and reduce the likelihood of injuries, property damage, and downtime.

- Quality assurance: UL certification requires strict adherence to manufacturing processes and quality control measures. This ensures that every panel built in a UL panel building shop meets the same high standards for quality, reliability, and durability.

- Enhanced marketability: UL certification is recognized and respected worldwide, and having a UL panel building shop. They can provide a competitive edge for companies operating in the electrical equipment and control panel industry.

- Customer confidence: Customers often require assurance that the electrical equipment they purchase meets safety standards. UL certification provides this assurance, and having a UL panel building shop can increase customer confidence in a company’s products and services.

In summary, having a UL panel building shop is essential for companies involved in the design. manufacture, and assembly of electrical control panels. Compliance with UL standards ensures safety, reduces risk, enhances quality, and increases marketability and customer confidence.

Certifications

SRS has a UL Panel Building Shop certification for UL508A / cUL 508A and is also ISO 9001 certified. We are also well versed in Hazardous panel Explosion proof rates or intrinsically safe.

Whether your needs are high the OEM panels, custom control panels, or SRS will assist in your needs.

UL’s safety Marks are the most credible and sought-after certification marks in North America. When regulators, specifiers, and end-product certifiers see the familiar UL Mark, they are confident that the panel has met the UL Panel certification requirements.

Increase your competitive advantage with a UL Panel

Offer your customers UL-certified general use, industrial machinery, elevator control, service equipment, and air conditioning. This also includes refrigeration equipment, fountain control, irrigation equipment, crane and flame control, and marine use panels and bid on jobs that specify UL-certified ICPs.

Cover all requirements of the UL Panel

UL Marks approvals confirm that proper component usage, enclosure environmental ratings, wiring and motor protection, and safety markings. This is needed to conform to the National Electrical Code (NEC) and Canadian Electrical Code (CEC) are met.

Greater efficiency of the UL Panel Building Shop

Eliminate red-tagged panels at the job site, along with the resulting delays and extra costs.

Widespread acceptance of the UL Panel

Benefit from the widespread acceptance of the UL Mark by regulatory authorities in every jurisdiction. This includes both the United States and Canada.

Increased component sourcing with a UL Panel

UL and CSA International have a formal component acceptance agreement. Hence, this permits the acceptance of specific components for use in end products; including industrial control panels. SRS’s customers now have flexibility when sourcing components.

CSA-certified components are accepted in UL-certified panels in addition to UL-certified components already permitted.

Requirements

The UL Mark meets requirements for applications such as general use, industrial machinery, elevator control, service equipment, and air conditioning. In addition, refrigeration equipment, fountain control, irrigation equipment, crane and flame control, and finally marine use.

Also, Our technical experts can help you “build safety in” while meeting the requirements set for you by regulators.