Butterfly Valve

$ 73.00 – $ 1,678.00

A butterfly valve is a quarter-turn rotary valve used to control the flow of fluids in pipelines. Its simple yet effective design consists of a disc mounted on a central shaft within a pipe, which can be rotated to regulate the flow by opening or closing, similar to the motion of a butterfly’s wings. The disc provides a tight seal against the seat when closed to prevent leakage.

Butterfly valves are available in various sizes, materials, and types to suit different applications and operating conditions. They are commonly used in industries such as water treatment, HVAC, chemical processing, and more, where reliable flow control is essential. With options for manual or automated operation, butterfly valves offer a cost-effective solution for throttling, isolating, or regulating fluid flow in pipelines, making them a versatile and widely used valve type in various industrial processes.

Description

A butterfly valve is a quarter-turn rotary valve that is commonly used to control the flow of a fluid within a system. It consists of a metal disc mounted on a rod in the center of the pipe, which rotates to open, close, or regulate the flow of the material passing through the pipeline. Moreover, the name “butterfly valve” originates from the wing-like action of the disc as it opens and closes.

Here is a detailed breakdown of the components and functioning of a typical butterfly valve:

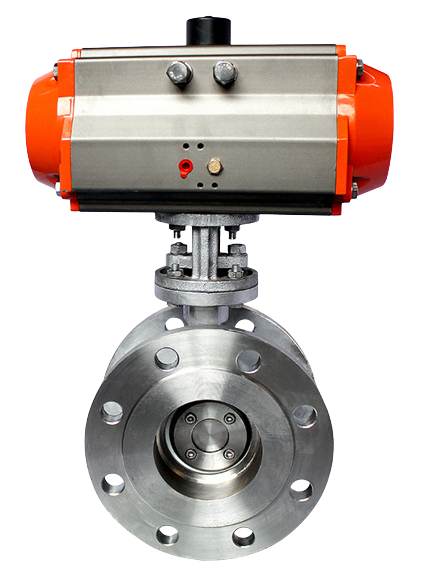

The body of a butterfly valve is a cylindrical structure that houses the disc and stem assembly. Designers have made it to withstand the pressure of the fluid passing through the pipeline. In addition, butterfly valves come in various materials such as cast iron and stainless steel. Other types come in carbon steel, PVC, or other alloys, depending on the application and the type of fluid being controlled.

Disc

The disc of the butterfly valve is the primary element responsible for regulating the flow. Attaching it to a stem that connects to the actuator allows the disc to rotate 90 degrees. It will go from fully closed to fully open positions. Moreover, the disc can be constructed from materials like stainless steel and cast iron. Depending on the specific requirements of the application, manufacturers can rubber-line or polymer-coat the materials.

The seat of the butterfly valve is the portion where the disc comes into contact to achieve a complete seal when closed. Furthermore, various materials such as rubber and PTFE can achieve the sealing. Other types include metal, ensuring a tight shut-off to prevent leakage during operation.

The shaft connects the disc to the actuator, allowing the disc to rotate within the valve body. Designers must ensure it withstands the torque needed to open or close the valve. It also effectively transmits the actuator’s motion to the disc.

Manually or Automatic?

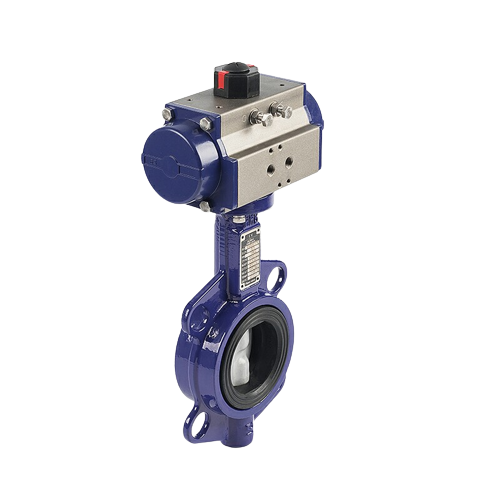

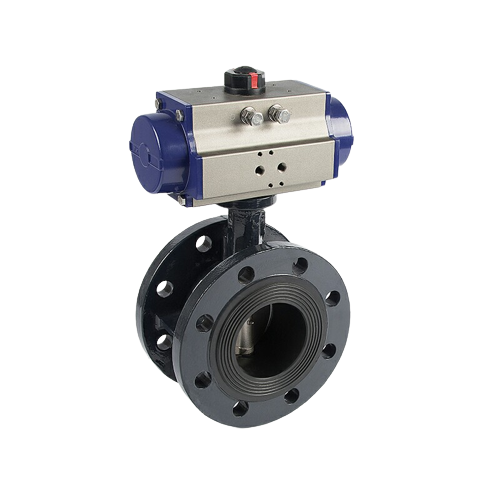

Users can operate butterfly valves manually or automatically using various types of actuators. In addition, manual actuators typically consist of a hand lever or gear operator, while automatic actuators include pneumatic, electric, or hydraulic options. These actuators can remotely control the opening and closing of the valve. This is based on signals from a control system or operator.

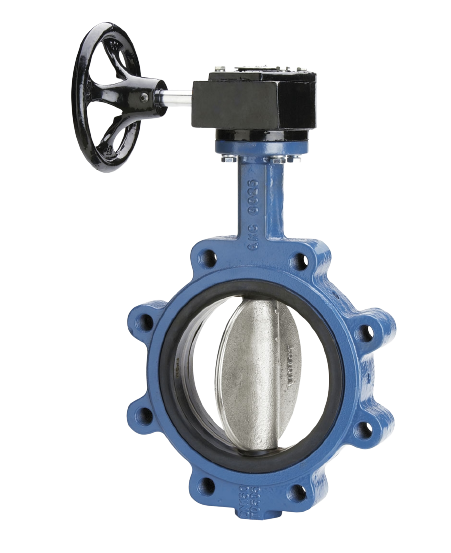

Butterfly valves can be classified based on their connection type as lug type or wafer type. Lug-type butterfly valves have threaded inserts at both sides of the valve body. This would enable users to mount them between two flanges. In the end, manufacturers design Wafer-type butterfly valves to fit between two flanges without needing additional bolts. This makes them a more compact and cost-effective option.

Versatile Butterfly Valve

Butterfly valves are versatile and find applications in various industries such as water treatment and HVAC systems. Other applications include chemical processing, oil and gas, power generation, and more. They also find use in throttling, isolating, or regulating flow in pipelines that carry liquids, gases, or slurries.

In conclusion, butterfly valves are popular for their simple design, quick operation, and reliable performance in controlling fluid flow. Their versatility, cost-effectiveness, and ease of maintenance make them a preferred choice for a wide range of industrial applications.

Specifications

- Valve pressure rating 200 psi

- 225°F continuous and 250°F intermittent service

- Lug style

- EPDM or Buna (others available) molded-in seat liner

- Stainless Disc

- Stainless steel stem with copper bushings

- Operating mechanism: Bare stem, infinite position plate and lock, lever lock, manual gear operator and pneumatic/electric automation

- Lead-free*

- Not recommended for steam service

- Designed to meet MSS SP-67

- MSS SP-25 (markings)

- Designed to meet API 609

- U.S. Coast Guard Category A

- California Health and Safety Code Section 116875

- Vermont Act 193

- Size range 2″ to 12″

Q&A

Q: What is a butterfly valve?

A: A butterfly valve is a quarter-turn rotary valve used to control the flow of fluids in pipelines.

Q: How does a butterfly valve operate?

A: A butterfly valve operates by using a disc mounted on a central shaft within a pipe. The disc can be rotated to regulate flow by opening, closing, or partially obstructing the passageway.

Q: What are the common applications of butterfly valves?

A: Butterfly valves are commonly used in industries such as water treatment, HVAC systems, chemical processing, oil and gas, and power generation for throttling, isolating, or regulating flow in pipelines.

Q: What are the advantages of butterfly valves?

A: Some advantages of butterfly valves include their simple design, quick operation, low cost, ease of maintenance, and suitability for a wide range of applications.

Q: What types of actuators are used with butterfly valves?

A: Butterfly valves can be operated manually using hand levers or gear operators, or automatically using pneumatic, electric, or hydraulic actuators.

Q: How are butterfly valves classified based on connection type?

A: Butterfly valves can be classified as lug type or wafer type. Lug-type valves have threaded inserts for mounting between flanges, while wafer-type valves fit between flanges without additional bolts.

Advantages / Disadvantages

Advantages of Butterfly Valves

Cost-Effective: Butterfly valves are generally more cost-effective compared to other types of valves.

Quick Operation: They offer fast operation with a quarter-turn, allowing for efficient flow control.

Simple Design: Their simple design makes them easy to install, operate, and maintain.

Low-Pressure Drop: Butterfly valves have low-pressure drops, minimizing energy consumption.

Space-Saving: Wafer-type butterfly valves are compact and do not require a lot of space for installation.

Versatility: They are suitable for a wide range of applications and can handle various types of fluids.

Reduced Maintenance: Due to their fewer parts and simple design, butterfly valves often require less maintenance.

Disadvantages of Butterfly Valves

Limitations in Sealing: Butterfly valves may have limitations in achieving a perfect seal, leading to potential leakage issues.

Throttling Capability: Compared to globe or ball valves, butterfly valves may have limitations in precise throttling control.

Pressure Limitations: High-pressure applications may exceed the pressure capabilities of some butterfly valves.

Cavitation Risk: In certain conditions, butterfly valves are susceptible to cavitation, which can damage the valve components.

Wear and Tear: Constant cycling and high-velocity flows can lead to wear on the valve components.

Temperature Limitations: Butterfly valves may have temperature limitations depending on the materials used in construction.

Noise and Vibration: In certain conditions, butterfly valves can generate noise and vibration during operation, affecting surrounding components.

Applications

Butterfly valves are versatile components widely used in various industries and applications due to their benefits and effectiveness in controlling fluid flow. Some common applications of butterfly valves include:

Water and Wastewater Systems: Butterfly valves regulate the flow of water in municipal water supply systems, irrigation systems, water treatment plants, and wastewater treatment facilities.

HVAC Systems: Butterfly valves control the flow of water and air in heating, ventilation, and air conditioning systems for temperature regulation and energy efficiency.

Chemical Processing: Butterfly valves are used in chemical plants to handle a wide range of corrosive and abrasive chemicals due to their compatibility with different materials.

Oil and Gas Industry: Butterfly valves regulate the flow of fluids in pipelines, refineries, and offshore platforms for transportation, processing, and storage of oil and gas products.

Power Generation: Butterfly valves control the flow of steam, water, and other fluids in power plants to optimize energy production and ensure the efficient operation of turbines and generators.

Food and Beverage Processing: Butterfly valves are used in food and beverage processing to control the flow of liquids, slurries, and gases in various stages of production and packaging.

Pharmaceutical Industry: Butterfly valves play a crucial role in pharmaceutical manufacturing processes to ensure precise control of fluid flow and maintain sterile conditions.

Shipbuilding and Marine Industry: Butterfly valves are used in ship systems for ballast control, firefighting systems, cooling water circulation, and other marine applications.

These are just a few examples of the diverse applications of butterfly valves across different industries where reliable and efficient fluid flow control is essential.

Downloads

Drawings

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.