Description

Ball valves are versatile flow control valves commonly used in various industrial applications to regulate the flow of liquids or gases. They are categorized based on their construction as 1-piece, 2-piece, or 3-piece ball valves, each offering specific advantages and applications. Additionally, ball valves come with different connection ends, including FNPT, flanged, and sanitary Tri-clamp ends, catering to diverse installation requirements. Materials such as carbon steel, 304 stainless steel (304SS), and 316 stainless steel (316SS) are commonly used for their construction, providing properties like strength, corrosion resistance, and durability.

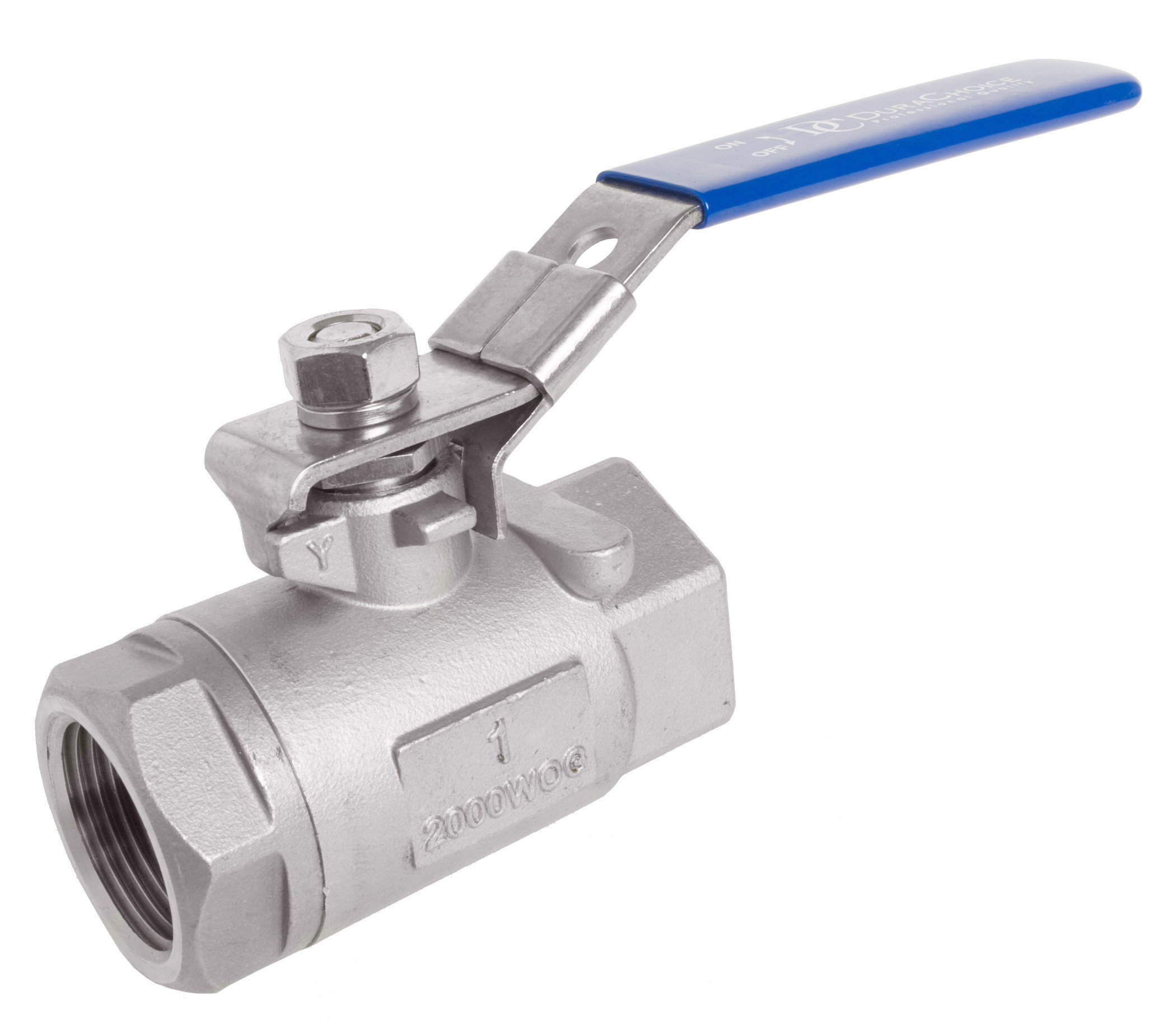

1-Piece Ball Valves:

1-piece ball valves consist of a single housing that integrates the ball and seat. They are compact, lightweight, and generally cost-effective. These valves are designed for simple on/off flow control applications and are easy to install and maintain. However, they offer limited flexibility for repair or maintenance due to their one-piece design.

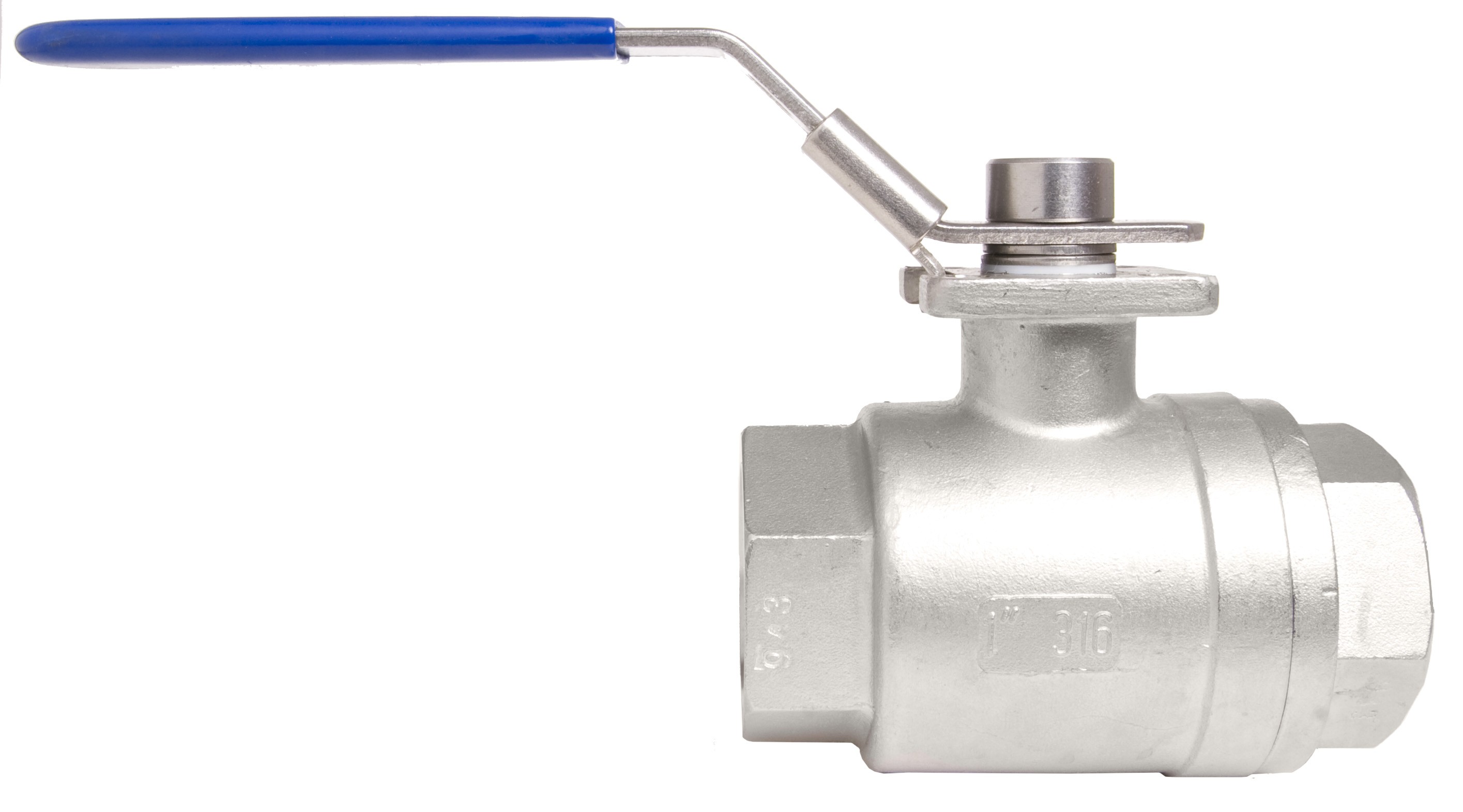

2-Piece Ball Valves:

2-piece ball valves are constructed with two separate pieces — one containing the ball and stem assembly and the other housing the seat. This design allows for easier disassembly, maintenance, and repair compared to 1-piece ball valves. They are suitable for a wider range of applications and offer greater flexibility in terms of customization and end connections.

3-Piece Ball Valves:

3-piece ball valves consist of three separate pieces — a body with two end caps, allowing the middle section to be removed without disturbing the piping connections. This design facilitates easy maintenance, cleaning, and servicing, making them ideal for applications where regular maintenance is required. 3-piece ball valves offer superior versatility and durability compared to 1-piece and 2-piece valves.

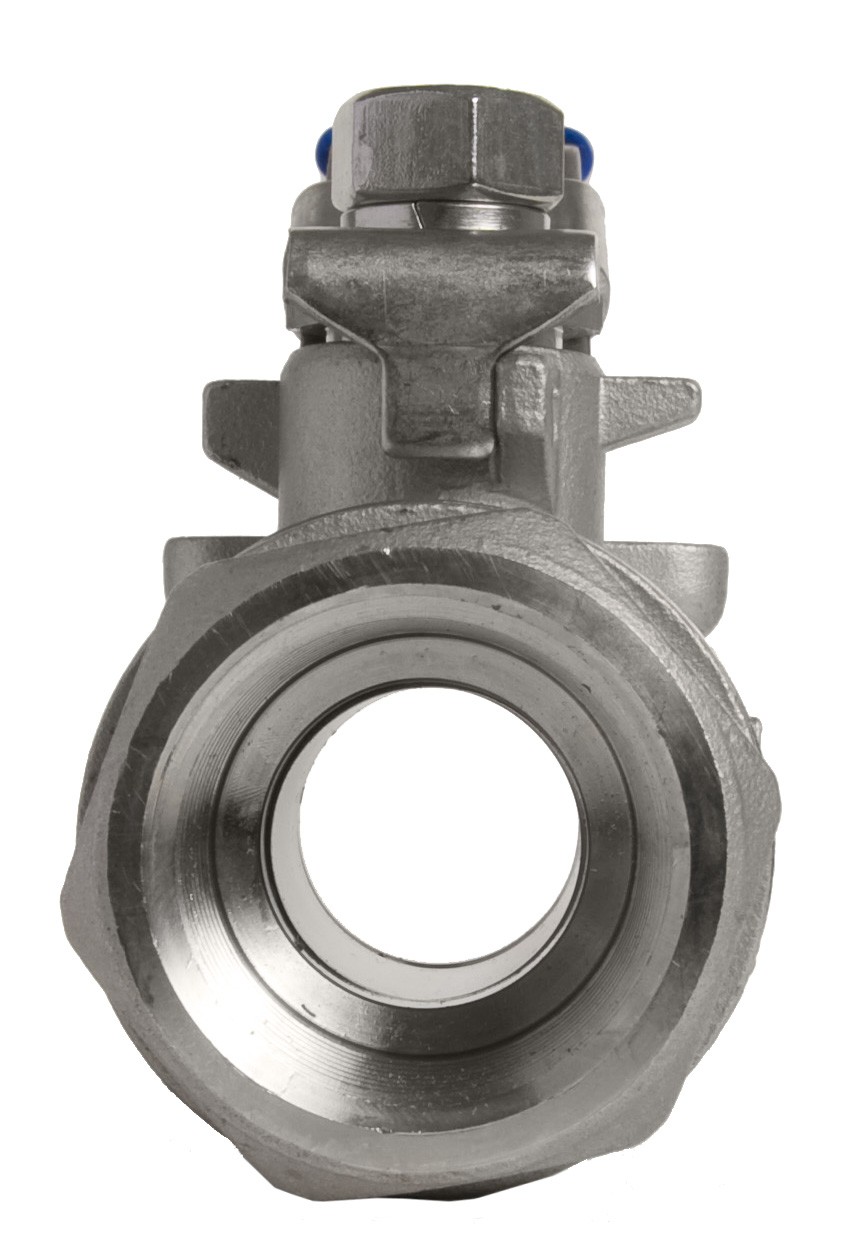

Connection Ends:

Ball valves come with different connection ends to suit various piping systems. FNPT (Female National Pipe Thread) connections provide a threaded connection for easy installation into female threaded pipes or fittings. Flanged connections feature flat discs with holes for bolting onto flanged pipes, providing a secure and leak-proof attachment. Sanitary Tri-clamp ends are designed for hygienic applications in industries such as food and pharmaceuticals, ensuring cleanliness and easy disassembly for cleaning and sterilization purposes.

Materials:

Ball valves are manufactured using different materials to suit specific application requirements. Carbon steel ball valves are durable and cost-effective, suitable for applications with moderate pressure and temperature conditions. 304 stainless steel (304SS) offers good corrosion resistance and is commonly used in general industrial applications. 316 stainless steel (316SS) provides superior corrosion resistance and is ideal for applications requiring high chemical resistance or exposure to harsh environments.

In conclusion, ball valves are essential components for flow control in industrial systems, with varying designs such as 1-piece, 2-piece, and 3-piece valves catering to different needs. The choice of connection ends and materials, including FNPT, flanged, sanitary Tri-clamp ends, and carbon steel, 304SS, or 316SS, depends on the specific application requirements for durability, compatibility, and performance.

Specifications

The specifications of a ball valve typically include key details that define its design, construction, and operational capabilities. Here are the typical specifications you might find for a ball valve:

Size: The size specification indicates the nominal diameter of the valve, usually expressed in inches or millimeters, and denotes the size of the pipeline for which the valve is designed.

Pressure rating: This specification defines the maximum pressure at which the valve can safely operate, often specified in pounds per square inch (psi) or bars. It is crucial to ensure the valve is compatible with the operating pressure of the system.

Temperature rating: The temperature rating specifies the range of temperatures within which the valve can effectively function without compromising its integrity or performance. The temperature rating is typically expressed in degrees Celsius or Fahrenheit.

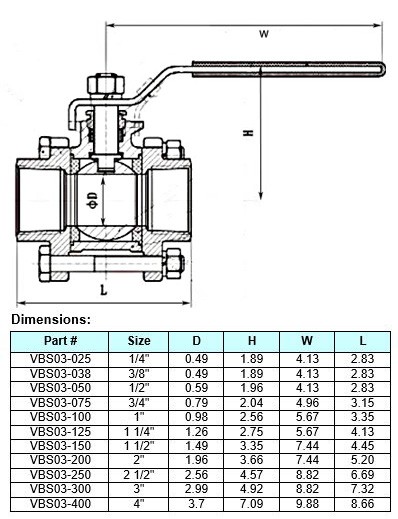

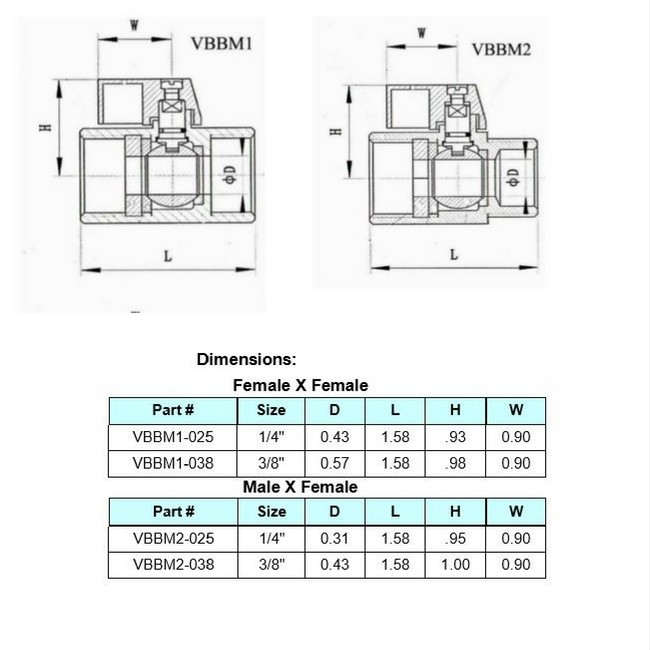

Dimensions

| Pipe Size |

1/2″ – 6″. Above that call for price. |

Details

| Body Material |

Carbon Steel, 304, 316 Stainless Steel |

| Body Style |

Inline |

| Max. Pressure |

600 PSIG CWP (Default), up to 2500 PSIG |

| Body Seal Material |

PTFE |

| Compliance |

RoHs |

| Stem Type |

Blowout Proof |

| Ball Valve Basic Body Material |

Stainless Steel |

| Seat Material |

PTFE |

| Handle Type |

Lever |

| Standards |

MSS-SP-110 |

| Connection Type |

Threaded FNPT x FNPT, Flanged Class 150, Socket, Tri-Clamps |

| Ball Valve Product Group |

Manual |

| Temp. Range |

-60 Degrees to 450 Degrees F |

| Ball Material |

316 stainless steel |

| Item |

Ball Valve |

| Handle Material |

Stainless Steel |

| Port |

Full |

| Valve Structure |

1, 2, and 3-Piece |

| Max. Steam Pressure |

150 PSI WSP |

| Stem Material |

316 Stainless Steel |

| General Connection Type |

Female NPT, RF Class 150 Flanged, Tri-Clamp |

| Sub-Category |

Stainless Steel Ball Valves |

|

Pieces

The primary difference between 1-piece, 2-piece, and 3-piece valves lies in their construction, maintenance, and ease of service. Understanding these differences can help in selecting the right type of valve for specific applications. Here’s a breakdown of the distinctions between these types of ball valves:

-

-

-

-

-

-

-

-

-

-

- 1-piece ball valves:

-

-

- Construction: 1-piece ball valves are integrated units where the body, ball, and end connections are all part of a single piece. This design offers a compact and simple configuration.

- Maintenance and repair: These valves are generally intended for applications where frequent maintenance or repair is not a primary concern. Due to their integrated design, 1-piece valves are not as easy to disassemble or service compared to multi-piece valves.

<li

>Cos

-

t and simplicity: 1-piece ball valves are often cost-effective and straightf

orward, mak

ing them suitable for applications where a basic, compact valve design is sufficient.

<l<

/ol>

</ol>i>2-

-

-

-

-

-

piece ball v

</ol>

alves:

<li

>tyle=”list

-style-type: none;”>

-

- “list-style-type: none;”>

-

- le=”list-style-type: none;”>>

- Construction: 2-piece ball valves consist of two separate pieces—the body and an end cap—that are bolted together. This modular design allows for easier disassembly and maintenance compared to 1-piece valves.</li>&amp;lt;/li><li>Mainte

- nance and repair: The two-piece construction permits maintenance and repair without requiring the entire valve to be removed from the pipeline. This contributes to reduced downtime and easier servicing.</li></li>

-

-

-

Flexibility and adaptability: 2-piece ball valves offer greater flexibility in ma

terial sele

ction and can be customized to suit

specific o

-

perating conditions, making them suitable for

a wide rang

- </u

<li style=”

list-style-

-

type: none

;”>l>

</li

>

- iece ball v

-

-

alves:

-

>Construction: 3-piece ball valves have an even more modular design, with the body and two en

d caps that

are bolted together. This construction allows for comple

te disassem

-

b

ly without

-

removing the entire valve from the pipeline.

- <li>Maintenance and repair: The 3-piece design

- offers the

-

- <ul>

-

- s=”yoast-text-mark”>le=”list-style-type: none;”>

- “list-style-type: none;”>

level of a

ntenance an

-

-

d repair, as the valve can be fully disassembled for i

nspection,<

cleaning,

component

ent. This m

-

-

- <ul>akes 3-piece valves ideal for applications

with string

-

- <ul>

- s=”yoast-text-mark”>tyle=”list-style-type: none;”>

>

nten</li>

ance requir

-

-

- yle=”list-style-type: none;”>

- Customization and serviceability: 3-piece ball valves allow for greater customization and repair options, as individual components can be replaced or modified, reducing overall maintenance costs over the valve’s lifecycle.

</ol

>

In summ

- le=”list-style-type: none;”>

-

ary, 1-piec

e ball val

-

ves are compact and straightforward, but offer li

mite

-

d serviceability and maintenance. 2-piece ball valves provide a balance between simplicity and ser

viceab

ility, making them sui

table for a

<ol><li style=”list-style-type: none;”>

wide range of applications. 3-p

iece ball

- <ol>valves offer the highest level of accessibility a

nd c

-

ustomization, making them ideal for applications with stringent maintenance needs and the requirem

ent fo

- ype: none;”>

-

r freque

nt adjustme

-

nts or repairs. Choosing t

he right ty

p

e of</p>

ball valve depends on the specific operational requirements and maintenance considerations of the application.</p>

Q&A

class=”yoast-text-mark”>class=”yoast-text-mark”>class=”yoast-text-mark”>class=”yoast-text-mark”>class=”yoast-text-mark”>class=”yoast-text-mark”>class=”yoast-text-mark”>class=”yoast-text-mark”>class=”yoast-text-mark”>class=”yoast-text-mark”>class=”yoast-text-mark”>class=”yoast-text-mark”>class=”yoast-text-mark”>style=”color: #121512;”>Q: What is a ball valve?

A: A ball valve is a type of valve used to control the flow of fluids, typically featuring a spherical closure unit (the ball) within the valve body that allows for opening and closing to control flow.

Q: What are the main advantages of using ball valves?

A: Ball valves are known for their reliability, tight shut-off capabilities, ease of operation, minimal maintenance requirements, and suitability for a wide range of applications and operating conditions.

e=”color: #121512;”>Q: What are the different types of ball valves?</p><p>e=”color: #121512;”>A: Ball valves come in various types, including full port, reduced port, single-piece, two-piece, three-piece, top-entry, cryogenic, and V-port ball valves, each designed to meet specific needs and applications.</p&gt;</p>

e=”color: #121512;”>Q: What are some common applications of ball valves?

<p><p style=”color: #121512;”>A: Ball valves are widely used in industries such as oil and gas, chemical processing, water and wastewater management, power generation, aerospace, pharmaceuticals, and general utility services.</p>

tyle=”color: #121512;”>Q: How do I select the right ball valve for a specific application?

requirements, flow control needs, material compatibility, environmental conditions, and any specific industry standards or regulations for guidance in selecting the appropriate ball valve.</p>

le=”color: #121512;”>Q: What are the main differences between 1-piece, 2-piece, and 3-piece ball valves?</p>

A: The primary differences lie in their construction, ease of maintenance, and repair capabilities. 1-piece valves are compact and integrated, 2-piece valves offer easier access for maintenance, and 3-piece valves provide the most accessibility for maintenance and customization.

Q: What is the process for installing a ball valve?

<p style=”color: #121512;”>A: The installation process involves preparing the workspace, selecting the appropriate valve, verifying its condition, preparing the pipeline, applying sealing materials, positioning and securing the valve, completing connections, conducting pressure tests, and verifying its alignment, tightness, and operation.

Q: Are ball valves suitable for throttling applications?</p>

A: While ball valves can regulate flow to some extent, they are not typically considered optimal for precise throttling applications. For precise flow control requirements, other types of valves such as globe valves or control valves are often more suitable.

=”yoast-text-mark”>: #121512;”>Q: How can I ensure the proper maintenance of ball valves?</p>

<p>yle=”color: #121512;”>A: Regular maintenance involves inspecting for leaks, verifying proper operation, cleaning the valve and its components, lubricating moving parts as needed, and replacing any worn or damaged seals or gaskets to ensure optimal performance.</p>

Q: What precautions should be taken when working with ball valves in hazardous environments?

A: In hazardous environments, it is crucial to adhere to safety guidelines, use appropriate personal protective equipment, follow industry-specific regulations, and consider the use of valves constructed from materials suitable for hazardous or corrosive fluids.

This Q&A provides a range of information that can help individuals understand the basics of ball valves, their applications, and considerations for selecting, installing, maintaining, and operating them in various industrial and commercial settings.

Installation

class=”yoast-text-mark”>class=”yoast-text-mark”>class=”yoast-text-mark”>class=”yoast-text-mark”>class=”yoast-text-mark”>class=”yoast-text-mark”>class=”yoast-text-mark”>class=”yoast-text-mark”>class=”yoast-text-mark”>class=”yoast-text-mark”>class=”yoast-text-mark”>class=”yoast-text-mark”>class=”yoast-text-mark”>style=”color: #121512;”>The installation of ball valves is a critical process that requires careful attention to ensure the valve operates effectively and safely within the intended system. Here’s a detailed procedure for the installation of ball valves:

-

-

-

-

-

-

- <ol style=”color: #121512;”>

-

<l

i style=”li<ol style=”color: #121512;”>st-style-type: none;”>

-

tyle=”color: #121512;”>

- style=”list-style-type: none;”>

e=”color: #121512;”>

- “list-style-type: none;”>

- <ol style=”color: #121512;”>

- Prepare the workspace: Begin by ensuring that the installation area is clean, well-lit, and free from any obstructions. Clear debris and ensure that the pipeline is properly supported and aligned.

- Select the appropriate valve: Choose a ball valve that is suitable for the specific application, taking into account factors such as fluid type, pressure, temperature, and flow requirements.</li>&l</ol

>

t;</li></o</li></ol>

l>li>Ver<ol sty

le=”color:

#121512;”>

-

class=”yoast-text-mark”>

-

“color: #121512;”>ify t<l

</li>

i cl<ol class=”yoast-text-mark”>ass=”yoast-text-mark”>”list-style-type: none;”>

-

- <ol class=”yoast-text-mark”>s=”yoast-text-mark”>

-

-

color

: #1215</ol

>

- </ol

-

>12;”

-

>

- <ol style=”color: #121512;”>he valve condition: Before installation, inspect the ball valve to en</li></li></li>

</ol></

-

li>sure

- none;”><ol class=”yoast-text-mark”>

-

tyle=”col

</li></ol</ol>

>or: #12151

2

-

;”>

- >e=”list-style-type: none;”>

-

-

- e=”list-style-type: none;”>

e=”color: #121512;”>

</

ol>;it is f

ree

-

-

from

any damage

or d

</ol

>

efec

- le=”list-style-type: none;”>

-

-

-

<li

style=”lis

-

t-style-type: n

one;”>&l

t;ol style=”color: #121512;”>

- ype: none;”>

ts

<

/ol><li style=”list-style-type: none;”>. Chec</ol>

-

tyle=”color: #121512;”>

- =”list

-

-

style=”color: #121512;”>-style-type: none;”>&

lt;ol style

=”color: #121512;”>k for

</li>

</li></li>

prop</p><ol style=”color: #121512;”>

- <ol style=”color: #121512;”>er operation of the valv

e, i

ncluding the actuator (if appl

icable), th

- style=”list-style-type: none;”>

<l

i style=”li</p>

-

“color: #121512;”>st-style-type:

none;”>

;

-

-

e=”col

or: #121512

-

;”>e ball

movement, a

nd

the integr<ol style=”color: #121512;”>

<ul>

- =”list-style-type: none;”>

ity of seals a

nd g

as

kets.</li>

ine: P

and cu

o ac

commodate the ball valve. Ensure that the ends of the pipeline are clean, smooth, and free from any burrs or contaminants that could affect the valve’s performance.<

li>Apply appropriate sealing materials: Depending on the design of the ball valve and the type of connection (e.g., threaded, flanged, or welded), apply the appropriate sealing materials such as thread sealant, gaskets, or pipe joint compound as recommended by the valve manufacturer.

- Position the valve: Carefully position the ball valve in the pipeline, ensuring that it is aligned correctly and that the flow direction indicated on the valve matches the direction of the media flow.

<li><li&g

-

“color: #121512;”>t;Secure

the

<ol>v<p></li></ol>

alve

-

-

le=”color: #121512

;”><<

/ol>

li>tyle=</l</p>

i>

“list-style-type: none;”>

-

lass=”yo

ast-text-ma

rk”>

2151

<ol class=”yoast-text-mark”>

-

-

lass=”yoast-text-mark”&g

t;2</li>;”>

- tyle=”list-style-type: none;”>

: If the valve is a fla

nged type,

-

-

-

sty

</o

l>

le=”co

-

-

-

-

>lor: #121512;”&g

<p>t;

-

- style=”list-style-type: none;”><ol style=”color: #121512;”>

-

-

- yle=”list-style-type: none;”><ol class=”yoast-text-mark”>yle=”color: #121512;”>ensure that the flanges are

</li>

prop

-

-

-

-

-

-

- “list-style-type: none;”>

=”yoast-text-mark”>e

</o

l>

</ol>

r</o

-

-

-

-

-

-

l>

</ol>

ly aligned

-

-

-

-

-

a

</ol

>nd tighten

-

-

-

-

-

le=”color: #121512;”>e

-

- e=”list-sty

le-type: none;”>

-

-

-

-

-

d

as per t</

-

-

-

-

-

ol>

he m

<ol class=”yoast-text-mark”>

-

-

-

-

-

-

ss=”yoast-text-mark”>tyle=”color: #121512;”><li

class=”yoa

-

-

-

-

-

- e=”list-style-type: none;”>

<li style=”list-st

yle-type: n

-

-

-

-

-

one;”><li

style

-

-

-

-

-

=”list-style-type: none;”>

-

st-text-mark”>class=”yoast-text-mark”>style=”list-style-type: none;”><ol class=”yoas

t-text-mark

-

-

-

-

-

-

“>: #121512;”

>

-

-

-

-

-

- le=”list-style-type: none;”><ol style=”color: #121512;”>

-

- anufacturer

‘s spec

ifications.

-

For threaded

- c

<ol

-

-

-

class=”yoast-text-mark”>onnection

-

style=”color: #121512;”>s, use

appr<ol style=”color: #121512;”>opriate torque to secur

e the valve

-

-

-

without over-tightening.</li

>

-

-

-

le

<ol style=”color: #121512;”>

-

-

-

- <ul><li style=”list-style-type: none;”>

</li></ul>class=”yoa

</li>

<p>ark”>s

-

-

-

- e=”list-style-type: none;”>

-type:

-

-

-

none;”>

-

tyle=”color: #121512;”><</ol>

li style=”l

-

-

-

-

<l

i style=”li

-

-

-

- <ol style=”color: #121512;”>st-style-type: none;”><

ol style=”c

-

-

-

-

olor: #121512

;”>

-

-

-

l>i st

e: n

-

-

-

-

-

-

-

-

-

one;”></o

l>

</ol>;

<li

class

-

-

-

-

=”</yoastmark”>”yoast-text-mar

k”&g

-

-

-

t;e=”list-style-type: none;”>

-

-

=”yoast-tex

-

-

t-mark”>style=”color: #121

512;</li>

“>te c

-

-

-

-

onnections: If t

he b

-

-

-

all valve is part of a

<

/ol></ol>

</ol>

larger sys

<li styl

-

-

-

e=”list-style-type: none;”>

-

-

-

-

tyle=”color: #121512;”><

li class=”y

-

oast-text-mark”>le=”list-style-type: none;”>

-

-

-

-

- ype: none;”>

-

- tyle=”list-style-type: none;”><ol style=”color: #121512;”>t</ol>

</ol>

em,</li&gt;</li>

</

ol>

</ol>

complete th

-

-

-

-

-

- <ol style=”color: #121512;”><li style=”list-style-type: none;”>

-

style=”color: #121512;”>

-

-

<li style=”list-st

yle-type: n

one;”>

</ol

>;

- “list-style-type: none;”>

-

yle=”color: #121

512;”>

-

-

-

- le=”list-style-type: none;”>

-

-

e n</ol

>

ecessary co<ol style=”color: #121512;”>nnections

</li>

wit

h appro

-

priate pi</ol

>

- pe fittings

- <ol style=”color: #121512;”>

-

, adapter

s, or acc</

ol>

esso

-

-

-

ries

</li></li>to integrat

-

-

-

-

-

le=”co

lor: #12151

-

2;”><li

style

=”list-style-type: none;”>

-

le=”color: #121512;”>e the valve

int

-

-

-

l

>&l

-

-

-

t;/ol>

</ol>

system

effe

-

-

-

-

<li style=”list-

style-type:

-

-

-

none;”>

-

e=”color: #121512;”><l

i st

-

-

-

-

-

yle=”list-style-type: none;”>

-

- e=”list-style-type: none;”>

-

-

- =”list-style-type: none;”>

ctively.

- Verify tightness and alignment: Double-check all connections and ensure that they are properly tightened, sealed, and aligned according to the valve manufacturer’s guidelines.

- Conduct pressure tests: After installation, conduct pressure tests to verify the integrity of the system and the newly installed ball valve. Follow industry standards and safety procedures when conducting pressure testing.</li></li></li><li

>Docum

- e

- nt and label: Properly document the installation process and label the ball valve with necessary information such as operating instructions, service dates, and any specific operational details relevant to the valve.

<li>Perform operationa

l checks: O

-

-

-

-

-

-

-

li class=”yoast-text-mark”>le=”list-style-type: none;”>

-

-

-

=”col

or: #1

21512;”>nce the

installa</

-

ol>

tion i

-

-

-

fy t

-

-

-

-

he operation of the ball valve by opening and closing it to ensure that it functions correctly and smoothly.

</li><p class=”yoast-text-mark”>tyle=”color: #121512;”>It’s important to note that the installation procedure may vary depending on the specific type of ball valve, the requirements of the system, and industry standards. Always refer to the manufacturer’s installation guidelines and follow the appropriate safety procedures and best practices to ensure a successful and reliable installation.

Reviews

There are no reviews yet.